Water purifier with flip device

A water purifier and flip-top technology, applied in the field of deep filtration and purification of drinking water, can solve the problems of scaling on the inner wall of filter cartridges and pipelines, soaking cabinets, time-consuming charges, etc., to avoid inconvenience and service expenses, and low-cost manufacturing. requirements, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

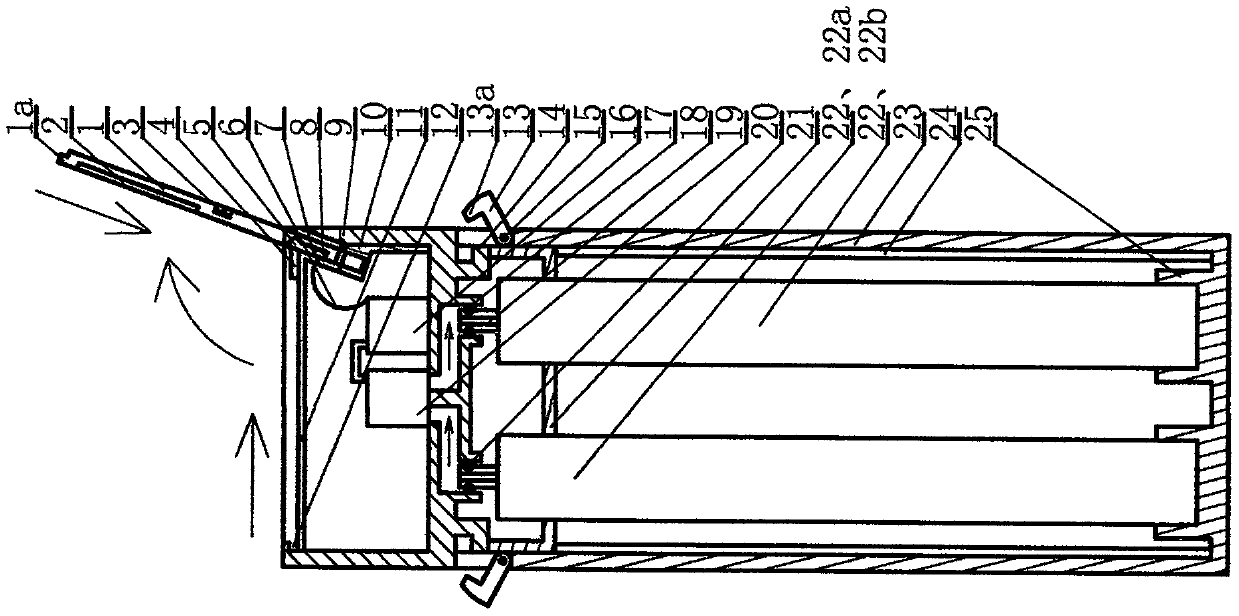

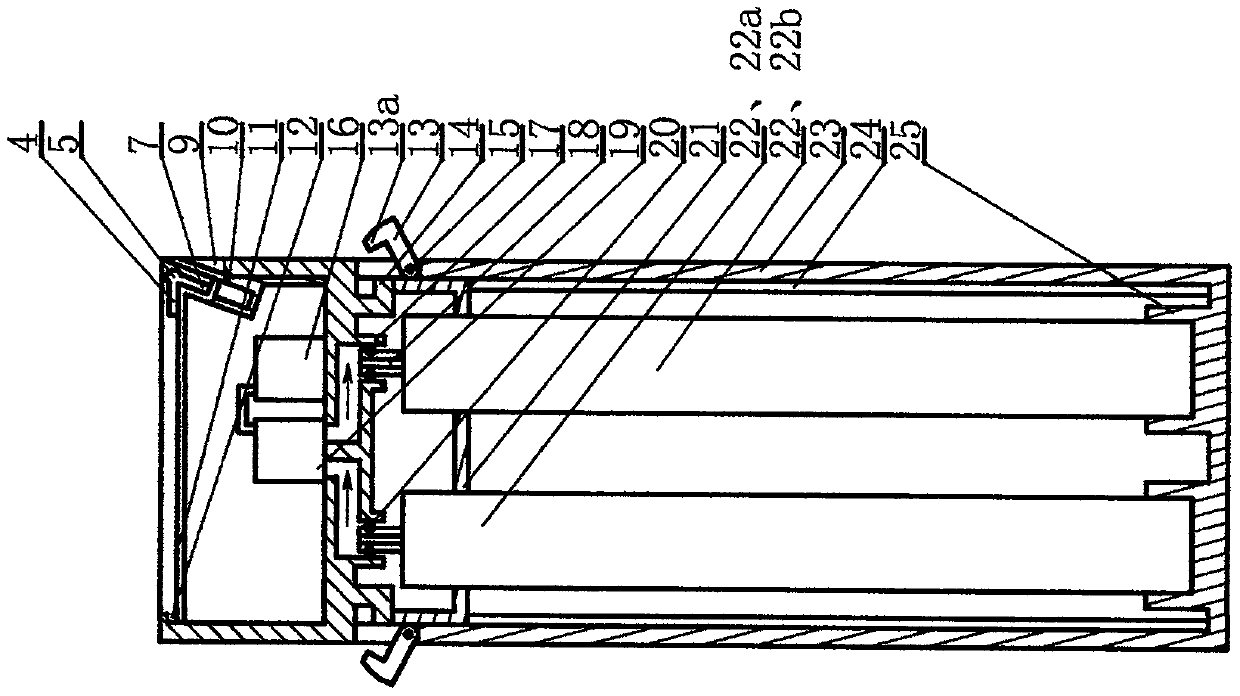

[0058]Example 1. A water purifier with a flip cover device, including a machine base and a water passage, a filter gall and a fastening device, a control part and a display part, a U-shaped filter chamber for placing and fixing the filter gall, and a U-shaped control chamber for placing the control parts; The output end is connected to the control part of the display part or the water control part or the electric control part or the combined device of the water control part and the electric control part; The upper and lower connections of the gallbladder chamber 23 form an integrated structure, and a plurality of filter gallbladders 22 and the water-passing control components are connected with the water-passing pipeline to form a filter channel. It also includes a flip cover with a protruding shaft 8 and a display part, a lateral movement groove 4 and a bracket 11, a shaft seat structure 5 and a flip device for the lower movement groove 7, wherein the upper end of the lower m...

Embodiment 2

[0065] Example 2. On the basis of Embodiment 1, a component selection screen will be displayed. The flip cover is provided with a built-in display screen and a cover plate; the cover plate placed on the outer surface of the flip cover cooperates with the flip cover to control the exposure of the display screen through a hinged structure or a guide rail moving structure. When the display screen needs to be used, the built-in display screen can be viewed directly by turning up or removing the cover plate placed on the outer surface of the flip cover.

[0066] On this basis, the flip cover is provided with dual display windows, such as setting LED indicator lights or digital display modules or exposed display screens on the outer side of the flip cover, setting the display screen for machine self-inspection as a built-in display screen and placing it on the flip cover. A cover plate is arranged on the outer surface.

Embodiment 3

[0067] Example 3. On the basis of the principle of Embodiment 1, a water purifier with a flip device includes a machine base and a water passage, a filter gall and a fastening device, a control component and a display component, and a U-shaped filter gall for placing and fixing the filter gall warehouse, U-shaped control chamber for placing control parts; the output end is connected to the control part of the display part or the water control part or the electric control part or the combination device of the water control part and the electric control part; The device connects the U-shaped control chamber 9 and the U-shaped gallbladder chamber 23 up and down to form an integrated structure, and connects a plurality of gallbladder filters 22 and water-passing control components with a water-passing pipeline to form a filter channel. It also includes a flip cover 1 with a protruding shaft 8 and a display part, a lateral movement groove 4 and a bracket 11, and a flip device with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com