Flexible cigarette carton turnover box with variable space

A variable and turnover box technology, applied in the direction of variable capacity containers, rigid containers, locking equipment, etc., can solve the problems of unfavorable distribution placement, displacement of cigarettes, etc., to achieve material reduction, good fit, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

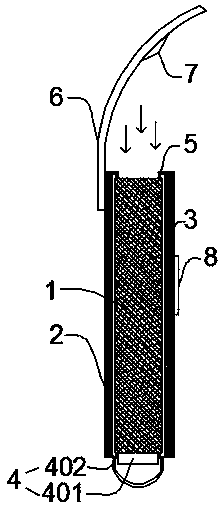

[0036] refer to figure 1 , figure 2 As shown, a space-variable flexible turnover box for cigarettes includes a box body. The box body is an existing bag box. The upper part of the box body is open and hollow. , used to form the box side wall from the tension band 1.

[0037] Wherein the tension band 1 is an existing elastic band, the height of the tension band 1 from the bottom to the top is less than the height of the box body, and the telescopic side wall of the box body is formed by the tension band 1, and the front wall of the above-mentioned box body is provided with a first fixed Forming plate 2, the second shaping plate 3 is provided on the rear wall of the above-mentioned box body, wherein the first shaping plate 2 and the second shaping plate 3 have the same size, and are installed on the front wall and the rear wall of the box body by conventional fixing methods, The material of the first shaping plate 2 and the second shaping plate 3 can be plastic or other mater...

Embodiment 2

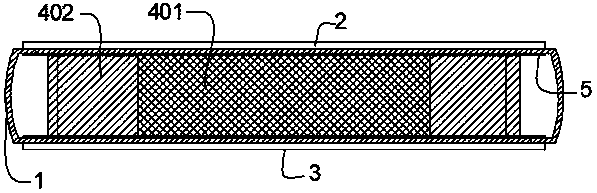

[0045] Based on the above examples, refer to image 3 , Figure 4As shown, another embodiment of the present invention is that the above-mentioned tension band 1 is one, and the above-mentioned tension band 1 is annular, and the above-mentioned tension band 1 runs through the gap between the contact cloth 5 and the inner wall of the box, and the above-mentioned tension band 1 against the contact cloth 5; during installation, the tension belt 1 is sleeved in the gap between the contact cloth 5 and the first shaping plate 2 and the second shaping plate 3.

[0046] Specifically, the tension belt 1 runs through the gap between the contact cloth 5 and the second sizing plate 3 and the gap between the contact cloth 5 and the first sizing plate 2; while the tension belt 1 is distributed on the first sizing plate 2 And the plate surface of the second sizing plate 3.

[0047] When in use, the cigarette is placed in the box, the contact cloth 5 touches the cigarette, and the tension b...

Embodiment 3

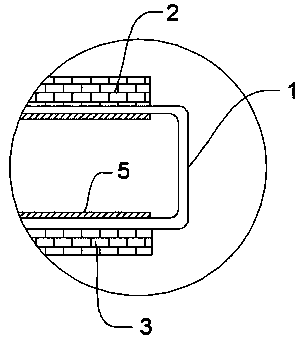

[0049] Based on the above examples, refer to Figure 5 , Figure 6 As shown, another embodiment of the present invention is, in order to save manufacturing cost, above-mentioned tension belt 1 is two or more, and above-mentioned tension belt 1 is sheet shape, and its tension belt 1 under the non-stretched state The minimum length is greater than or equal to the gap between the first shaping plate 2 and the second shaping plate 3 .

[0050] The end of the above-mentioned tension belt 1 extends into the gap between the contact cloth 5 and the inner wall of the box, and the above-mentioned tension belt 1 is respectively connected with the contact cloth 5 of the first sizing plate 2 and the second sizing plate 3 . The length of the tension band 1 is shorter than the length of the tension band 1 in Embodiment 2, wherein one end of the tension band 1 is fixed between the contact cloth 5 and the second sizing plate 3 sides; the other end of the tension band 1 It is fixed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com