Fireproof composite cable

A composite cable and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of internal core wire damage, economic loss, cable damage, etc., and achieve a good fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

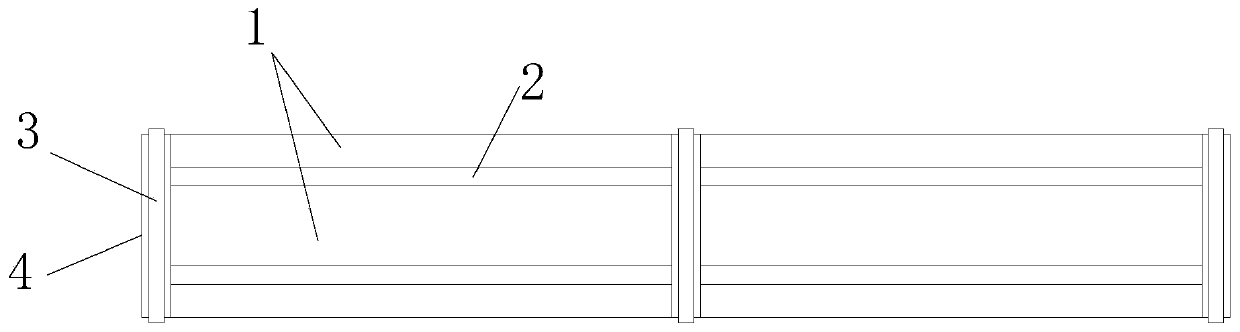

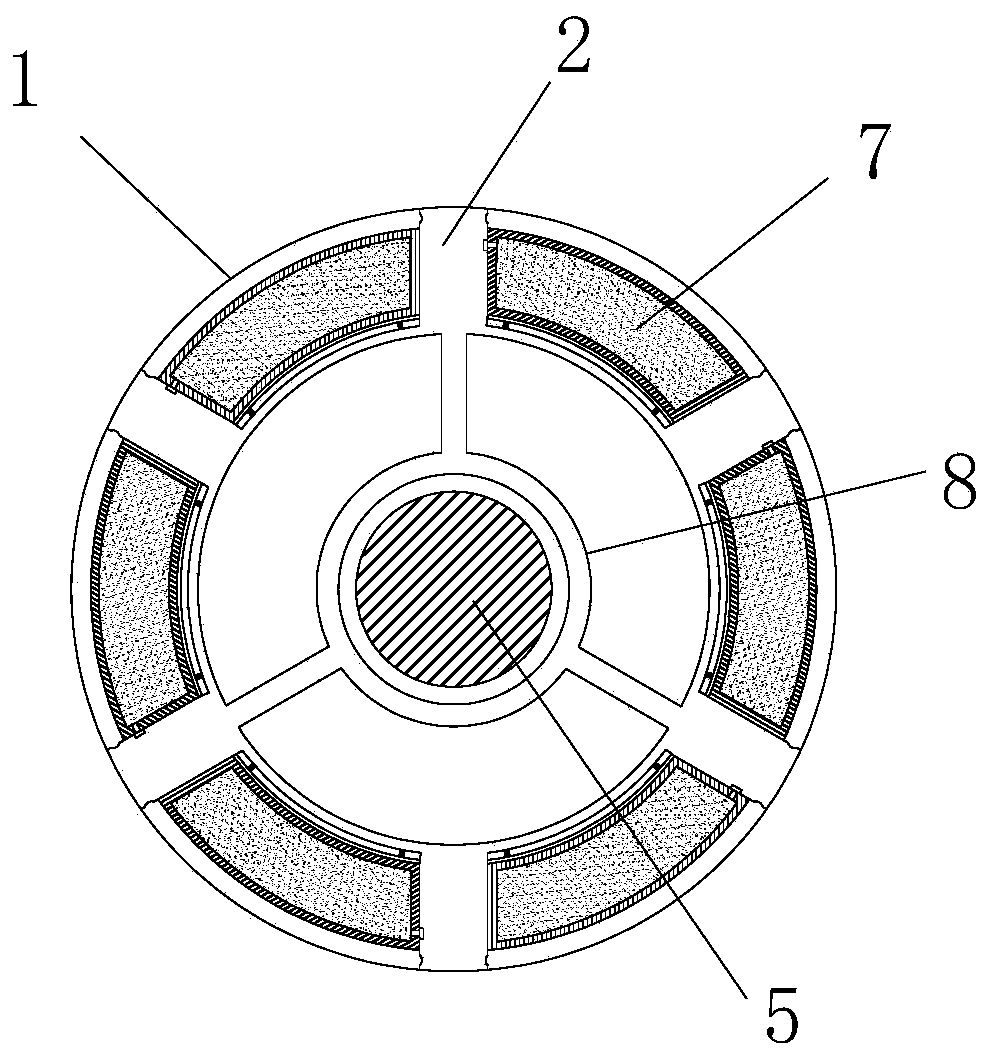

[0018] Such as figure 1 with figure 2 As shown, the fireproof composite cable is composed of more than one section of outer covering layer 2 and more than one connecting piece. A connecting piece is arranged between adjacent outer covering layers 2, and the outer covering layer 2 and the end surface of the connecting piece are fixed. touch;

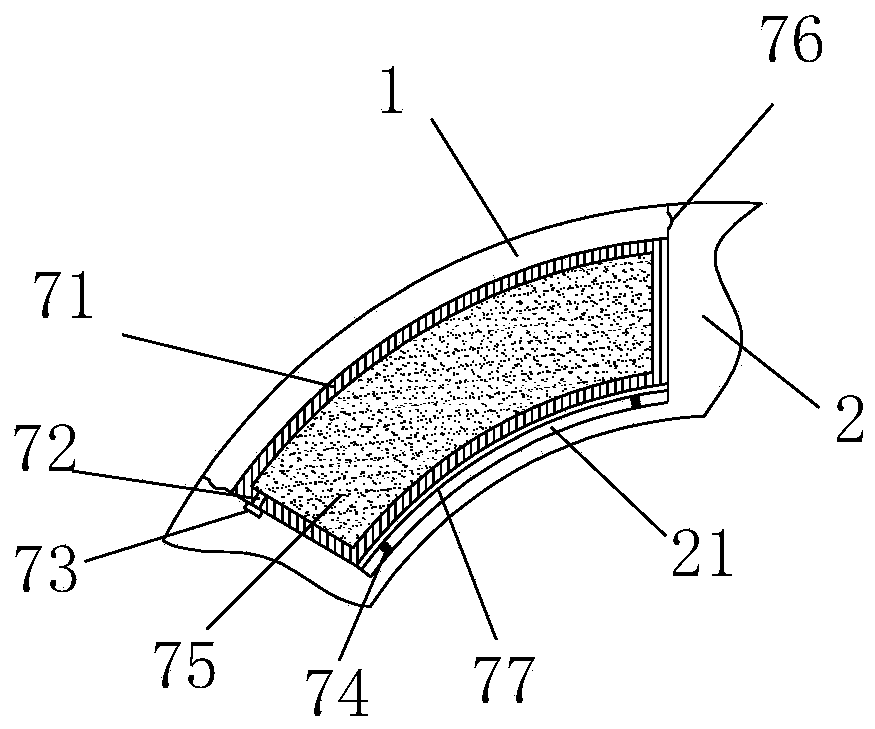

[0019] There are more than one concave cavities 21 around the outer layer on the outer layer 2, such as image 3 As shown, an expansion body 7 is filled in the concave cavity 21, and an inert gas is filled in the expansion body 7. A bottom layer 77 is arranged on the bottom of the expansion body 7, and more than one compression spring 74 is arranged on the bottom of the bottom layer 77. The compression spring 74 The bottom of the expansion body 7 is fixedly connected with the bottom surface of the concave cavity 21, and the outer end of the expansion body 7 is provided with a heat conduction sheet 1. The limit is in the concave cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com