Tunnel-before-wall-type crossed tunnel portal excavation supporting construction method

A construction method and intersection technology, which are used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem of the stability of the surrounding rock at the intersection without a systematic solution, avoid backfilling concrete, reduce over-excavation, save construction time and The effect of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

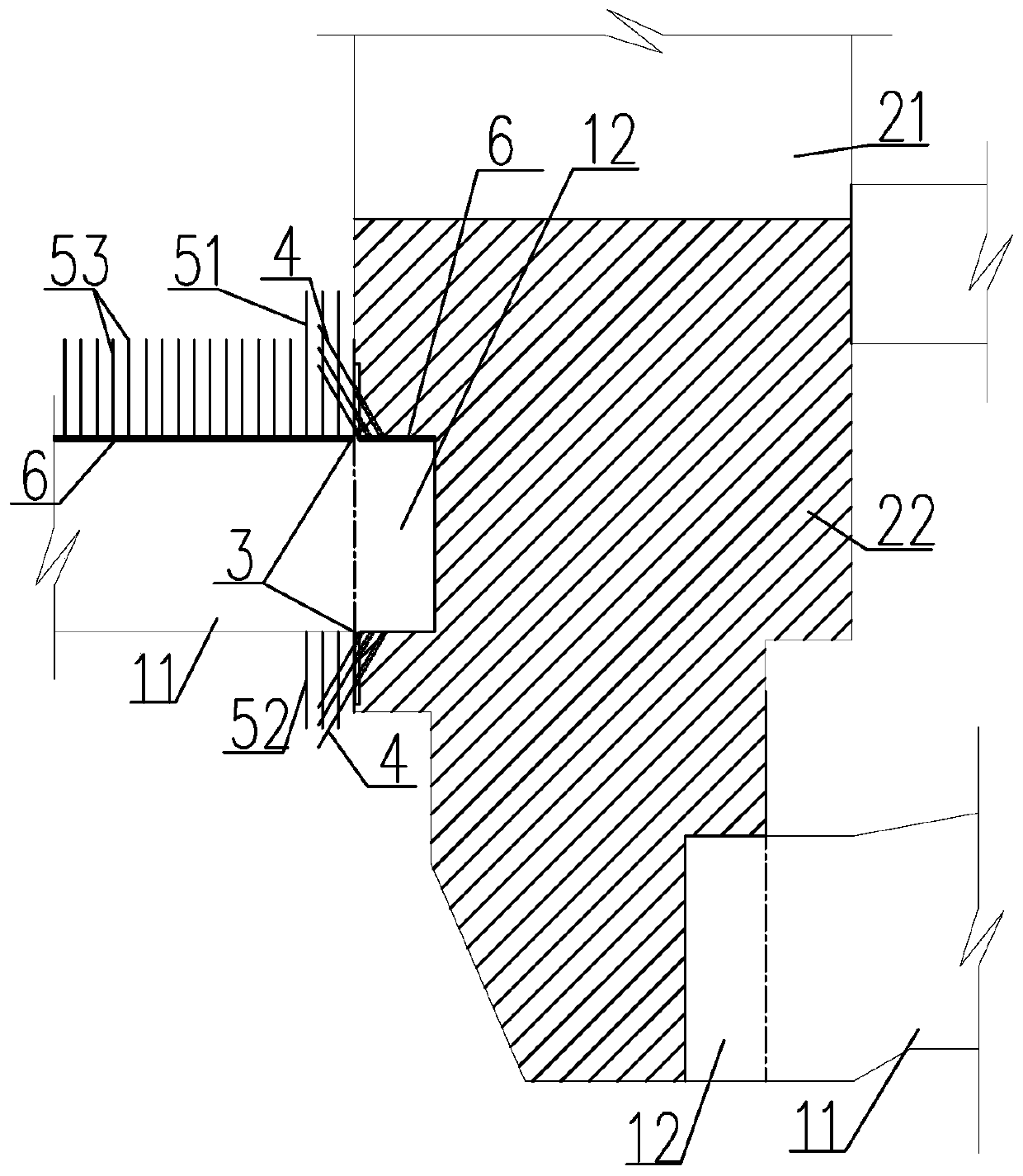

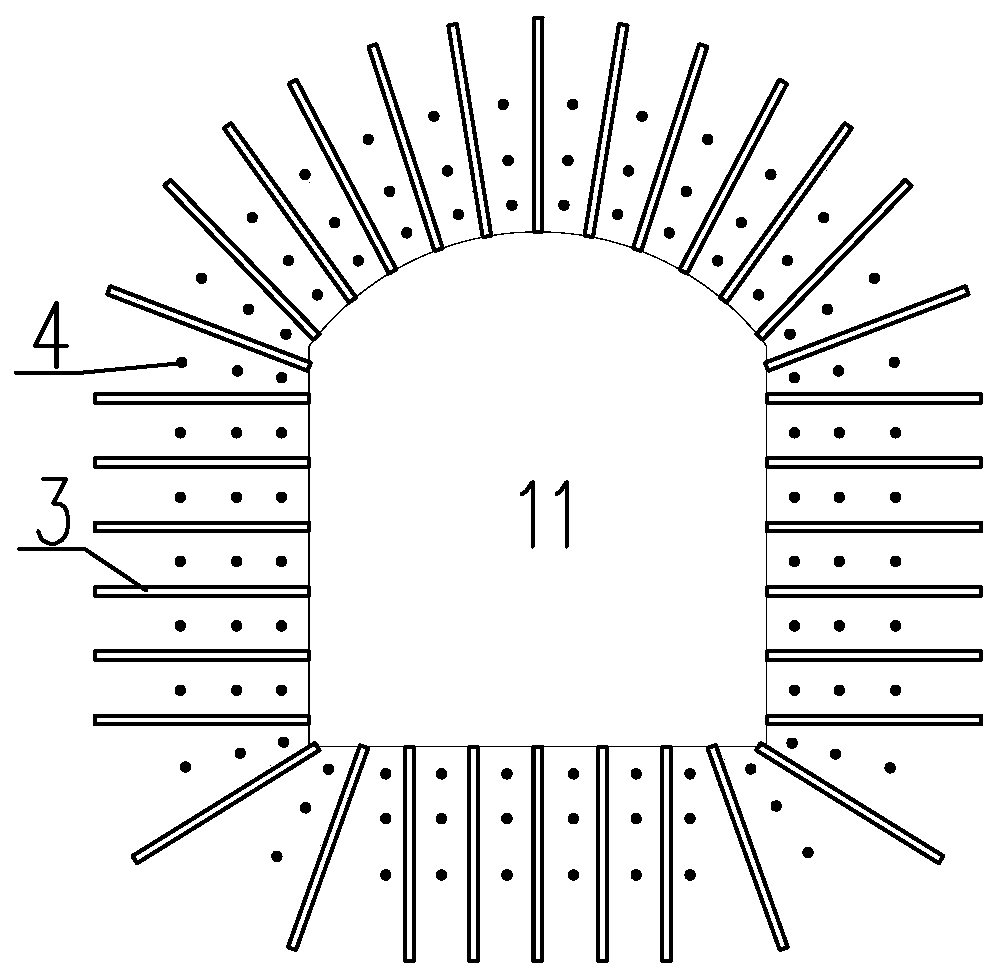

[0015] like figure 1 As shown, the excavation and support construction method of a hole-first and wall-type intersection of the present invention is used for excavation and support of large-scale underground caverns and tunnel intersections. During the excavation of the upper part of the cavern, simultaneously Excavation and support of the lower tunnel 11. exist figure 1 Among them, the reference numeral 21 represents the excavated section of the cavern, and the reference numeral 22 represents the unexcavated section of the cavern.

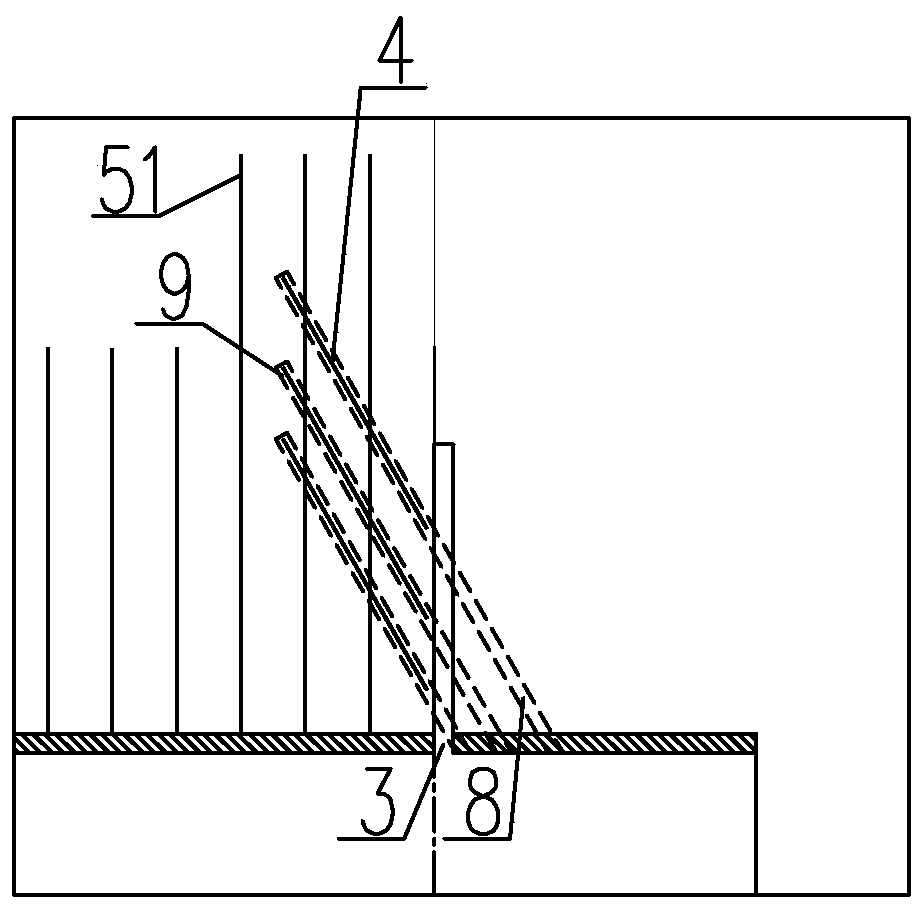

[0016] After the permanent section 11 of the tunnel is excavated to the designed structural surface of the side wall of the cavern, the reinforced concrete spraying layer 6 and the system anchor rod 53 shall be constructed on the side arch of the tunnel in time to complete the system spraying, anchoring and netting support, and then according to the size of the tunnel section Continue to excavate into the cavern to form a tunnel extension sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com