Steel casing pre-embedded construction technology

A construction technology and steel casing technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of structural waterproof damage, non-existence, and hidden dangers of water seepage in the floor, and achieve faster The construction progress, the casing is firmly fixed, and the effect of ensuring the quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it is not intended as a limitation of the present invention.

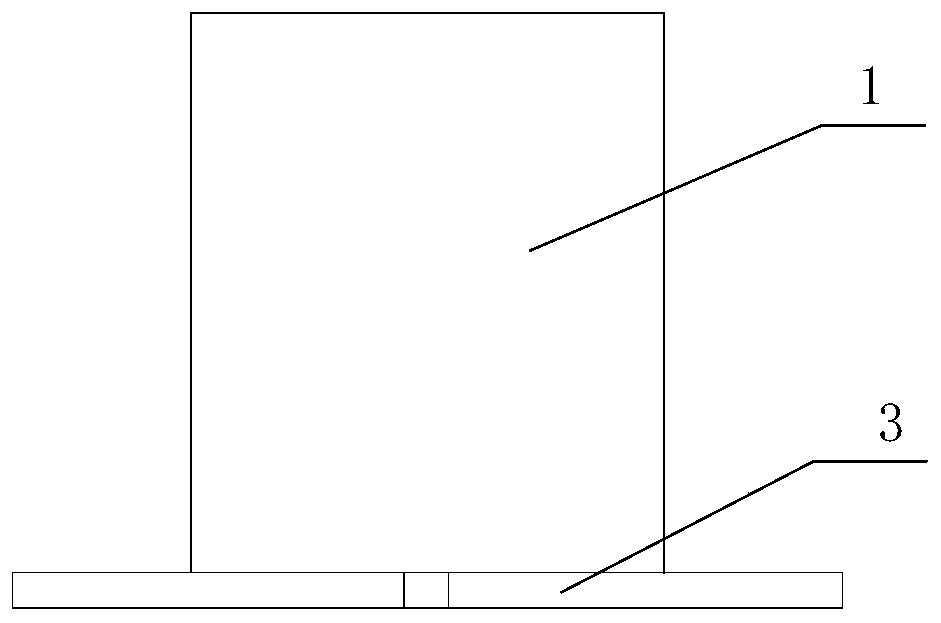

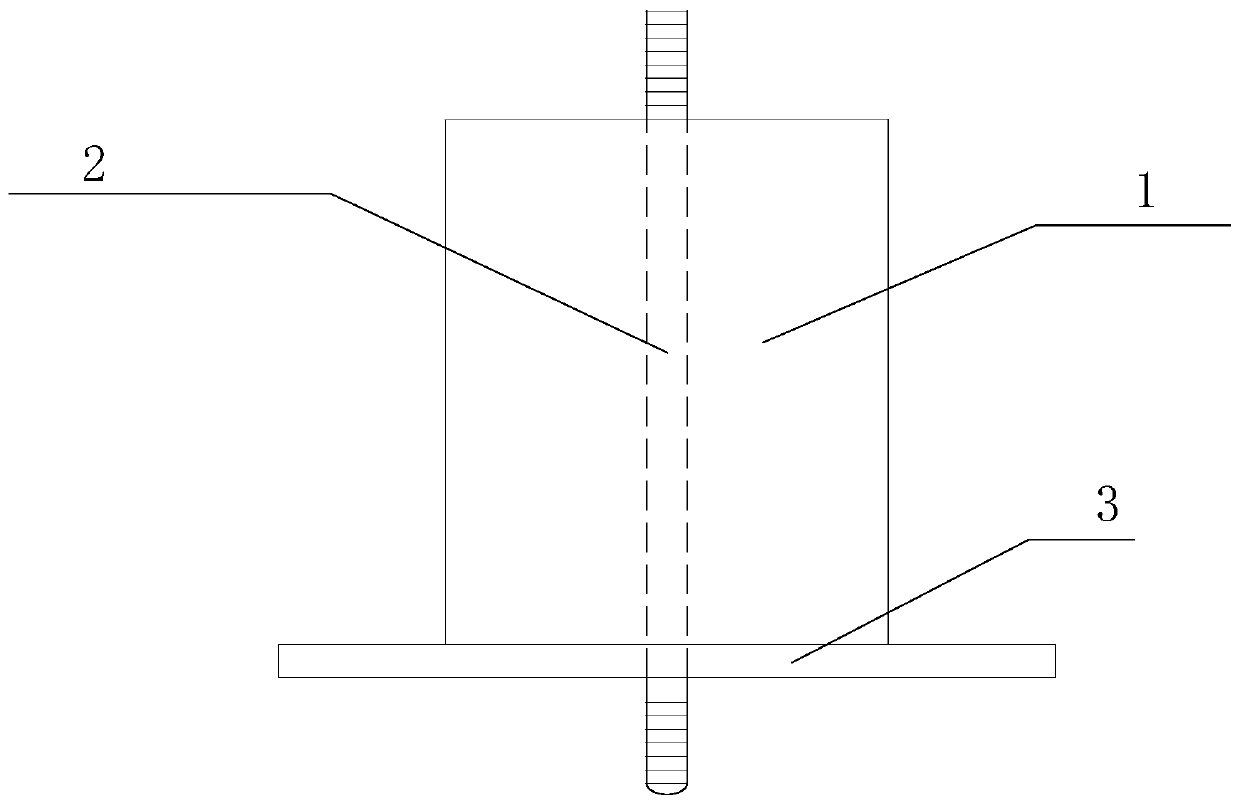

[0022] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention discloses a steel casing pre-embedded construction process, including:

[0023] Position through the casing, and then drill a hole at the center of the floor formwork casing 1;

[0024] Put the casing 1 in place, and pass the reinforcement screw 2 from the inside of the casing to the bottom of the floor formwork 3;

[0025] Tighten and reinforce the reinforcement screw at the bottom of the floor formwork 1;

[0026] Make a circular casing cover plate 5, then drill a round hole in the center of the cover plate according to the setting out, and then tighten it with nuts 4 on the cover plate;

[0027] After the installation of the casing is completed, the concrete pouring of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com