Concrete beam column pouring formwork frame and mounting method thereof

A technology of concrete and beams and columns, which is applied in the direction of construction, building structure, formwork/formwork components, etc., can solve the problems of not being too thick, low strength, waste of wood, etc., to reduce installation steps, increase service life, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

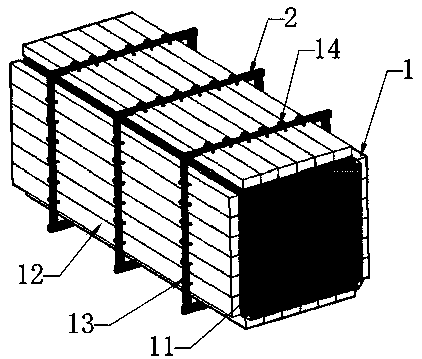

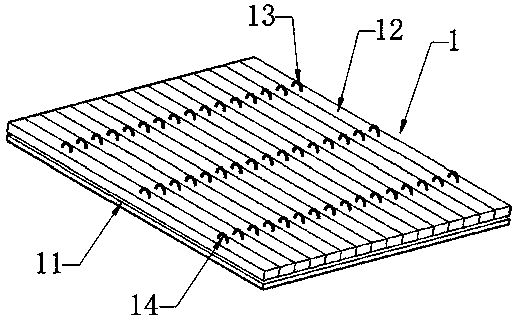

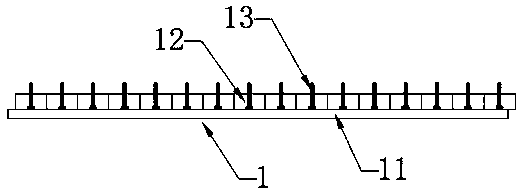

[0026] As shown in the figure, the concrete beam and column pouring formwork provided in this embodiment includes a formwork matching the shape of the beam and column, and the formwork is formed by bending two composite formworks 1 into a U shape and splicing together. The composite formwork 1 is composed of a flexible bottom layer 11 and a reinforcement layer fixedly installed on the back of the flexible bottom layer 11, the flexible bottom layer 11 is rectangular, and the reinforcement layer is composed of a plurality of rigid rectangular strips 12 vertically arranged along the width direction of the flexible bottom layer 11 The side ends of adjacent rigid rectangular strips 12 are attached to each other; a plurality of U-shaped buckles 13 are installed at intervals on the outer end surface of each composite template 1 reinforcement layer, and the opening side of the U-shaped buckles 13 is fixed on the hard In the rectangular bar 12, and arranged in multiple rows, an arc chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com