Windproof reinforcing method of cranes

A technology of cranes and anchors, applied in the field of crane windproof reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

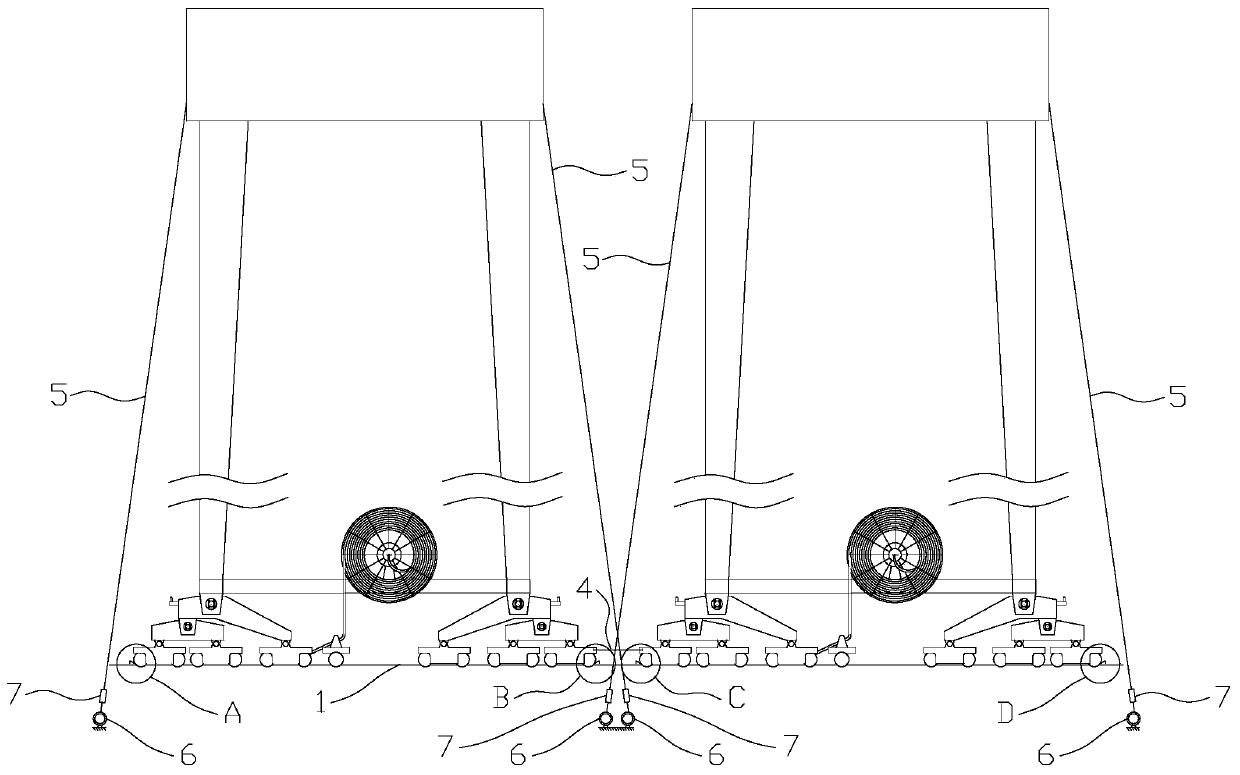

[0016] Such as Figure 1~2 As shown, a crane windproof reinforcement method includes placing a limit device on the wheel rail 1 to limit the movement of the wheel 2, anchoring the portal frame and the ground of the crane through a steel wire rope 5, and multiple cranes that will move on the same wheel rail 1 Close together end to end, the three reinforcement methods can be selected arbitrarily and used in combination to fix the crane relative to the surrounding ground, improve the typhoon resistance of the crane, and ensure that the crane can remain stable even in severe typhoon weather without being damaged. Blowing and tipping; where the limit device such as figure 2 Shown is the wheel stopper 3 clamped on the wheel rail 1, the bottom of the wheel stopper 3 is provided with a card slot matching the cross-sectional shape of the wheel rail 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com