Cutter drive device

A driving device and cutting knife technology, applied in metal processing, household components, household appliances, etc., can solve the problems of slow cutting speed, unstable air flow, complex and bulky structure, etc., so as to reduce the impact and improve production efficiency. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

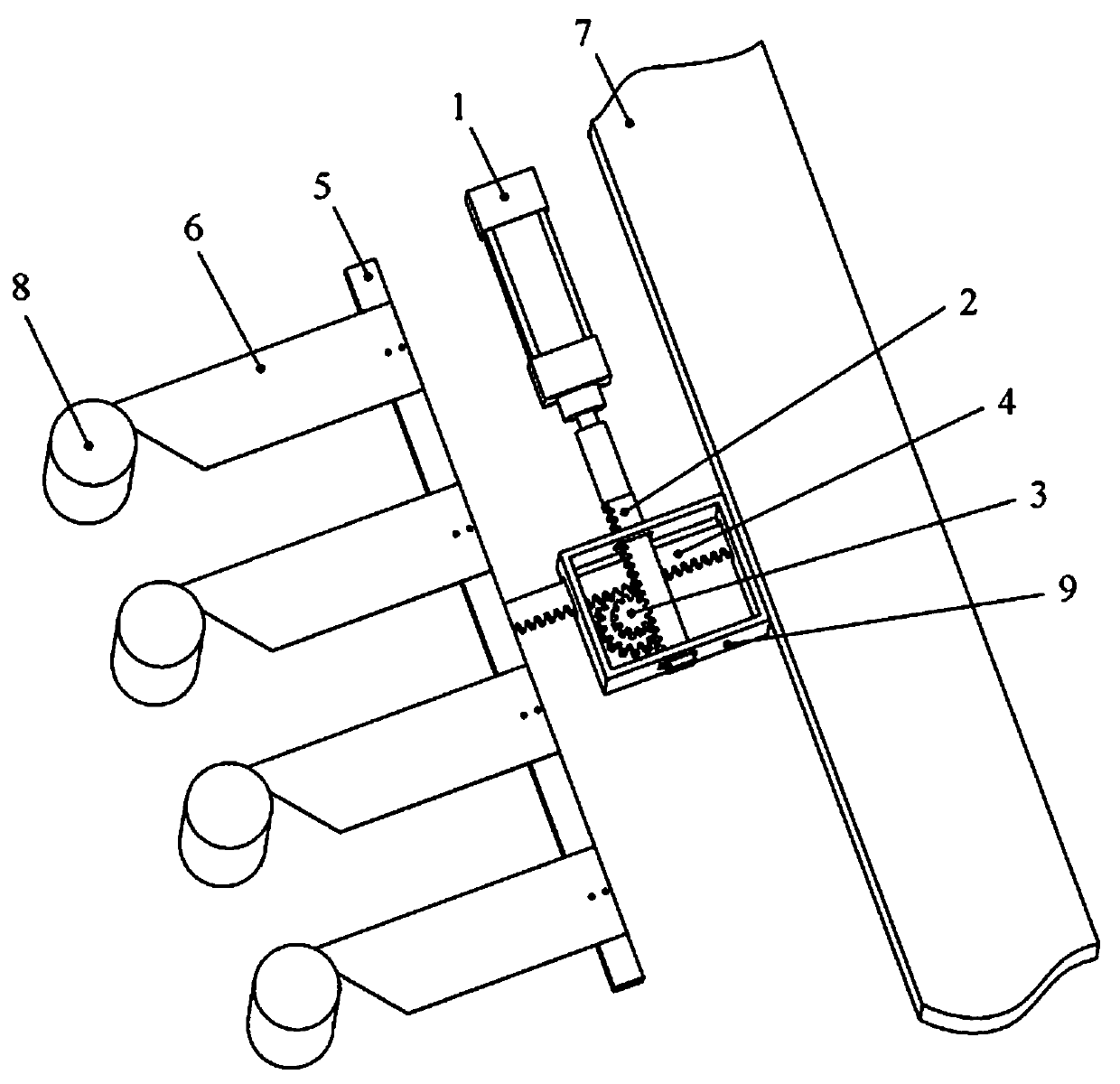

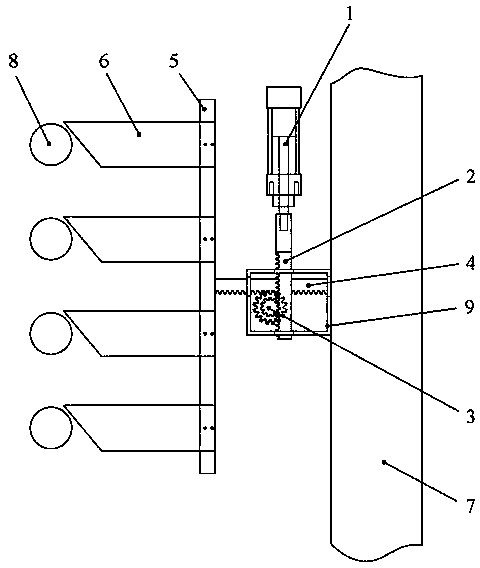

[0023] Such as figure 1 and figure 2 As shown, the present embodiment includes a cylinder 1, a cutter frame 5 and a cutter 6 installed on the cutter frame 5, a gear transmission mechanism is arranged between the cylinder 1 and the cutter frame 5, and the gear transmission mechanism includes a driving rack 2 , gear 3 and driven rack 4, gear 3 meshes with driving rack 2 and driven rack 4 respectively, driving rack 2 is coaxially connected with the telescopic rod of cylinder 1, and cylinder 1 drives driving rack 2 with the same To move, the driven rack 4 is arranged on the cutter frame 5.

[0024] The gear transmission mechanism is arranged on the frame beam 7, the frame beam 7 is provided with a gear box 9, the gear transmission mechanism is installed in the gear box 9, and the driving rack 2 and the driven rack 4 run through the gear box 9. Gear 3 is a double-circle gear composed of two large and small gears arranged coaxially. The driving rack 2 meshes with the pinion, and ...

Embodiment 2

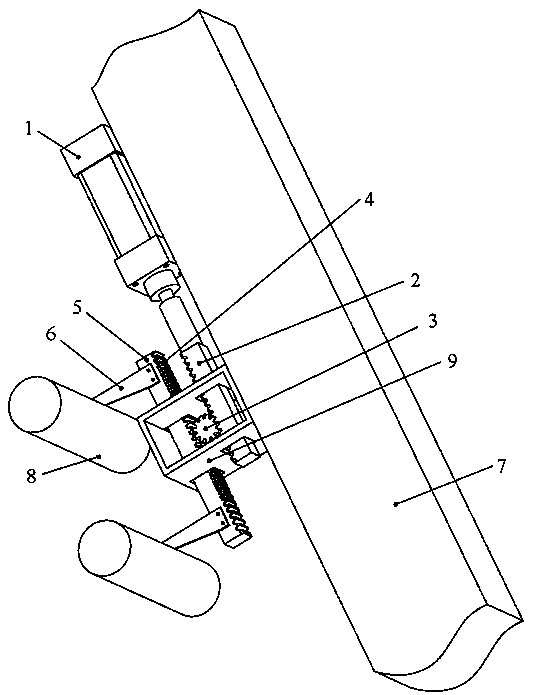

[0027] Such as image 3 and Figure 4 As shown, the present embodiment includes a cylinder 1, a cutter frame 5 and a cutter 6 installed on the cutter frame 5, a gear transmission mechanism is arranged between the cylinder 1 and the cutter frame 5, and the gear transmission mechanism includes a driving rack 2 , gear 3 and driven rack 4, gear 3 meshes with driving rack 2 and driven rack 4 respectively, driving rack 2 is coaxially connected with the telescopic rod of cylinder 1, and cylinder 1 drives driving rack 2 with the same To move, the driven rack 4 is arranged on the cutter frame 5.

[0028] The gear transmission mechanism is arranged on the frame beam 7, the frame beam 7 is provided with a gear box 9, the gear transmission mechanism is installed in the gear box 9, and the driving rack 2 and the driven rack 4 run through the gear box 9. The gear 3 is a single-turn gear, and the gear box 9 is provided with a driving rack through hole and a driven rack through hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com