System and method for repeatedly capturing microspheres based on pulse laser

A pulsed laser and microsphere technology, which is applied in the manipulation of neutral particles by radiation pressure, radiation/particle processing, nuclear engineering, etc., can solve problems such as low throwing efficiency and microspheres breaking away from the base surface, and achieve a high success rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further illustrate the present invention below in conjunction with accompanying drawing.

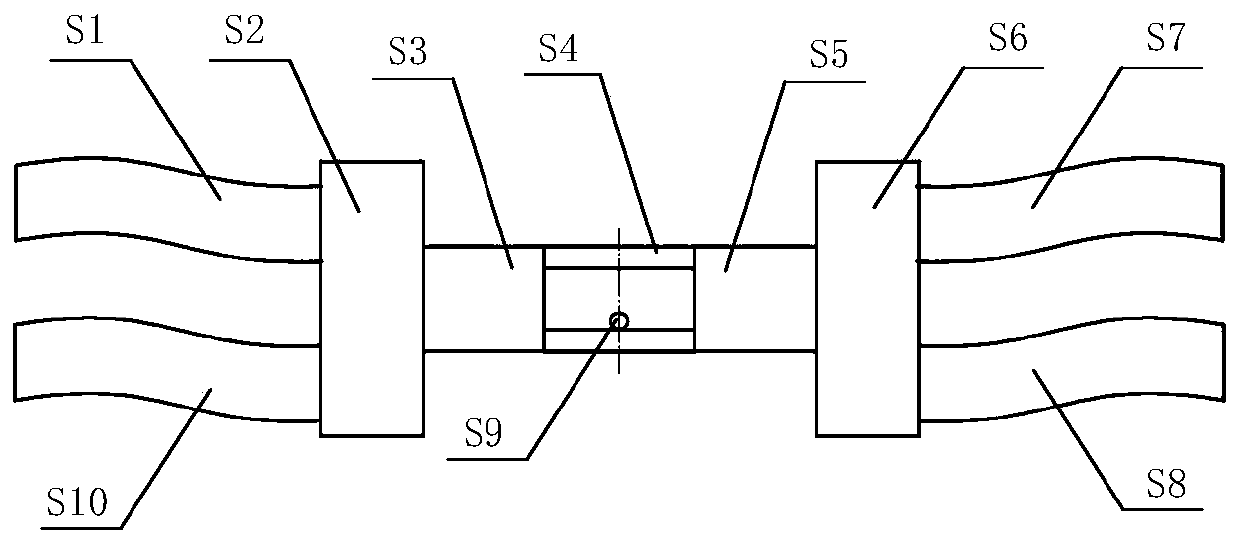

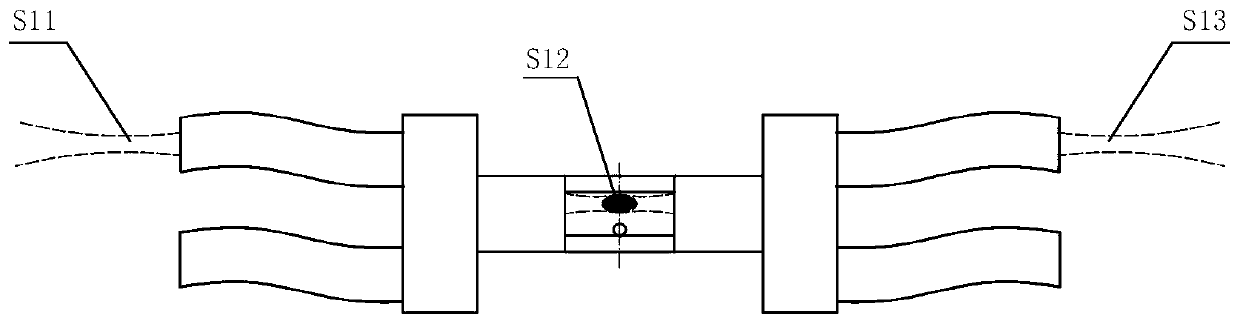

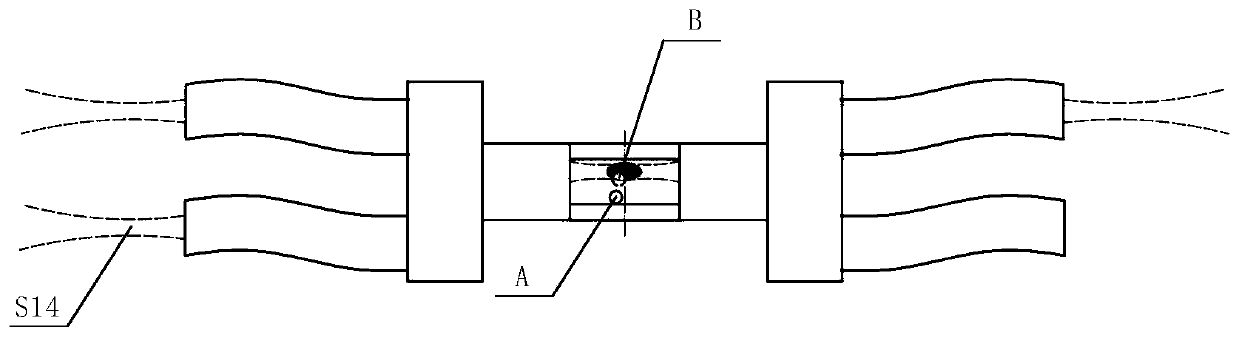

[0030] The system includes a capillary microcavity storing one or more microspheres, and two ends of the microcavity are fused with two sections of optical fibers to form a closed environment. One end of the two optical fibers is fused with a capillary, and the other end is coupled with two lasers, one of which is a continuous laser and the other is a pulsed laser. Two continuous laser beams traveling oppositely form an optical trap inside the capillary microcavity. Two beams of pulsed light are used to excite the microspheres to achieve branching.

[0031] like figure 1 As shown, the specific implementation includes left first optical fiber S1, left second optical fiber S10, left optical coupler S2, left fusion splicing optical fiber S3, capillary S4, microsphere S9, right fusion splicing optical fiber S5, right optical coupler S6, right first Optical fiber S7 and right second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com