Intelligent scheduling method and system for industrial cigarette transportation

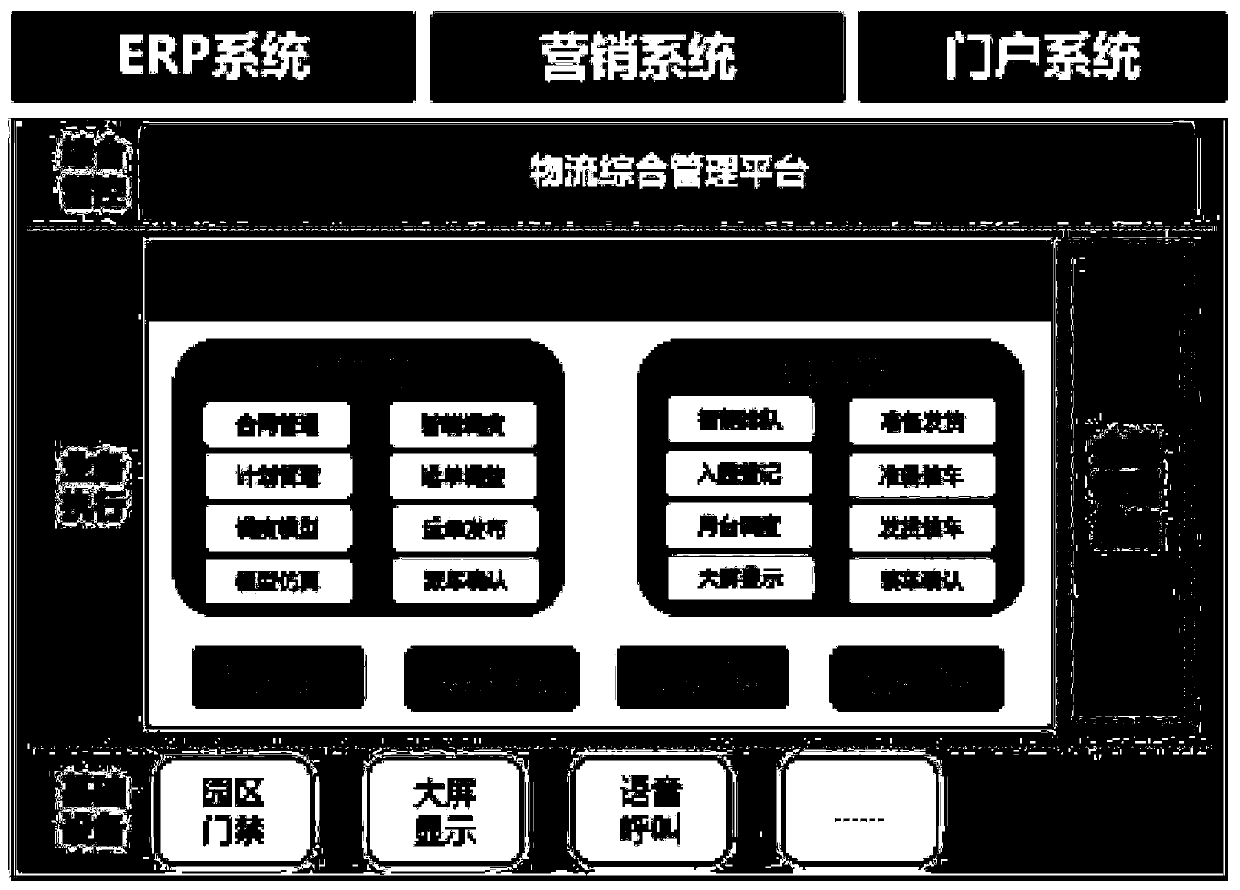

An intelligent dispatching and cigarette technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve the problems of manual dispatching occupation, high labor cost, lack of scientific and reasonable route planning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

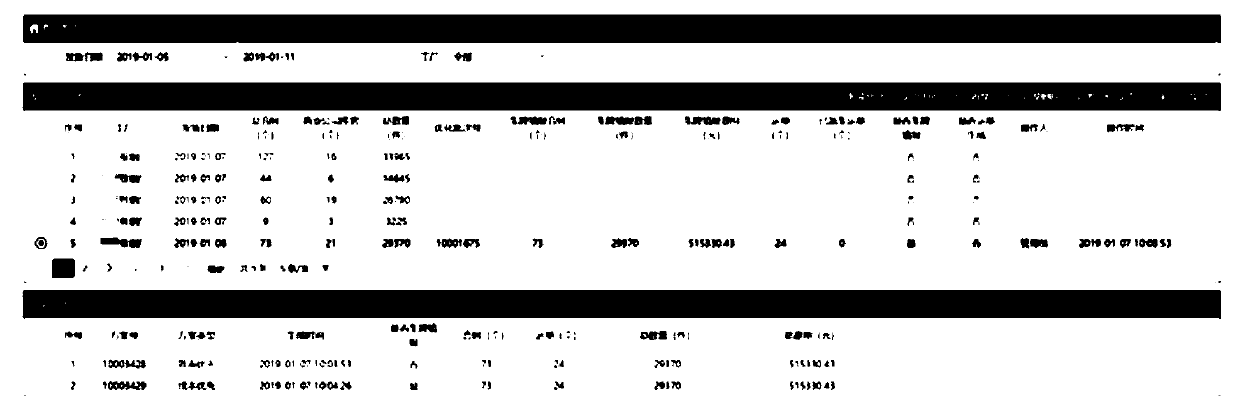

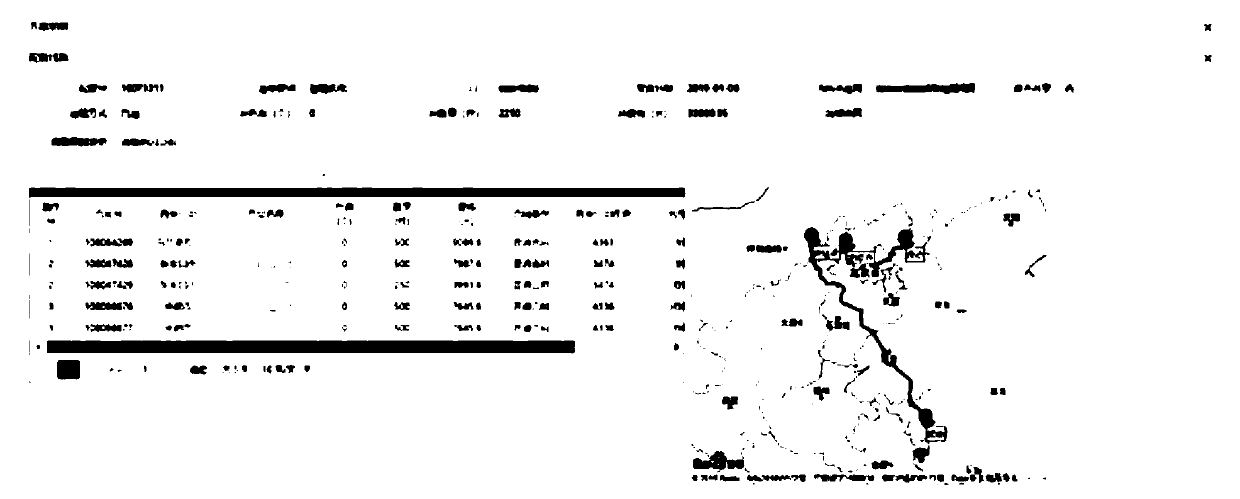

Examples

Embodiment Construction

[0099] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed descriptions are given in conjunction with specific embodiments and accompanying drawings.

[0100] Cigarette transportation costs of industrial enterprises are the largest single item of logistics costs. Cigarette transportation costs account for about 75% of the total cigarette logistics costs of industrial enterprises. Cigarette transportation is mainly by road transportation, and road transportation costs account for more than 90% of transportation costs. Therefore, for industrial enterprises, reducing the cost of cigarette transportation is an important area for companies to reduce costs and increase efficiency; reducing the cost of cigarette transportation by road is a top priority, and there is a lot of potential to tap.

[0101] Reasonable logistics and transportation scheduling optimization is an important way to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com