HOT PLUG DEVICE FOR PLC backboard

A hot-swap, backplane technology, applied in the field of PLC backplane, can solve the problems of normal operation, inability to communicate, and the reliability of the PLC system is greatly affected, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The above objects, features and advantages will be described in detail below with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily carry out the technical idea of the present invention. In the description of the embodiments of the present invention, if it is judged that the detailed description of the known technology associated with the present invention unnecessarily obscures the essence of the present invention, the detailed description of the known technology will be omitted. Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. Throughout the drawings, the same reference numerals designate the same or similar parts.

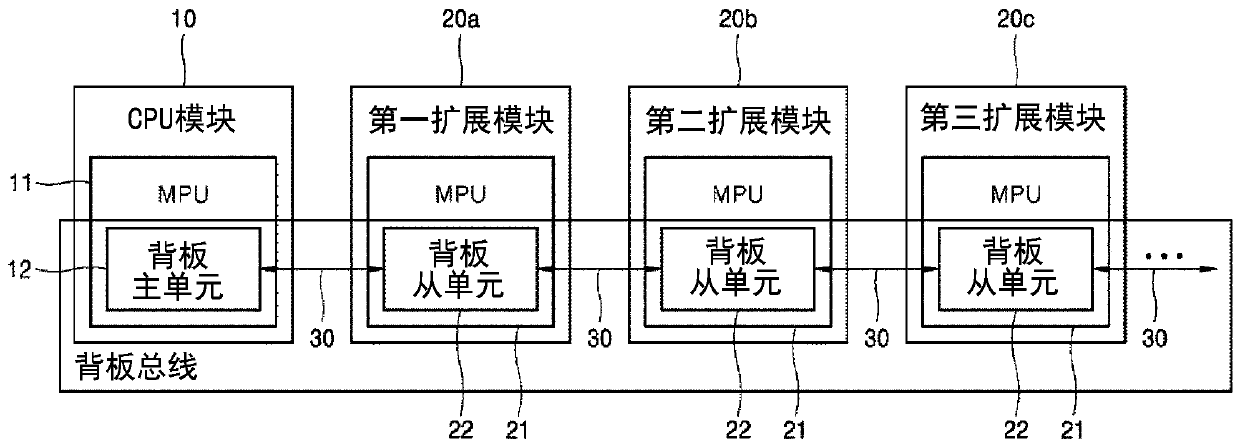

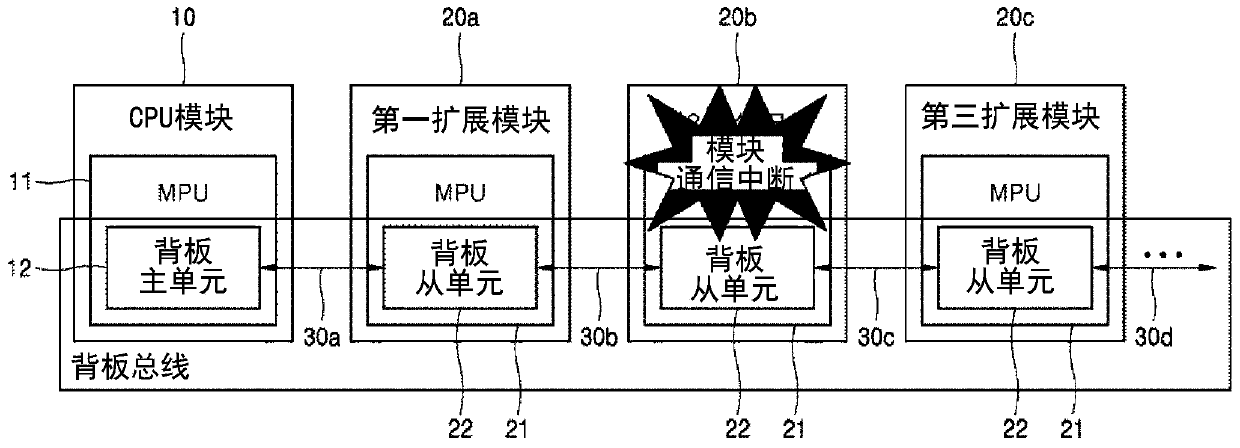

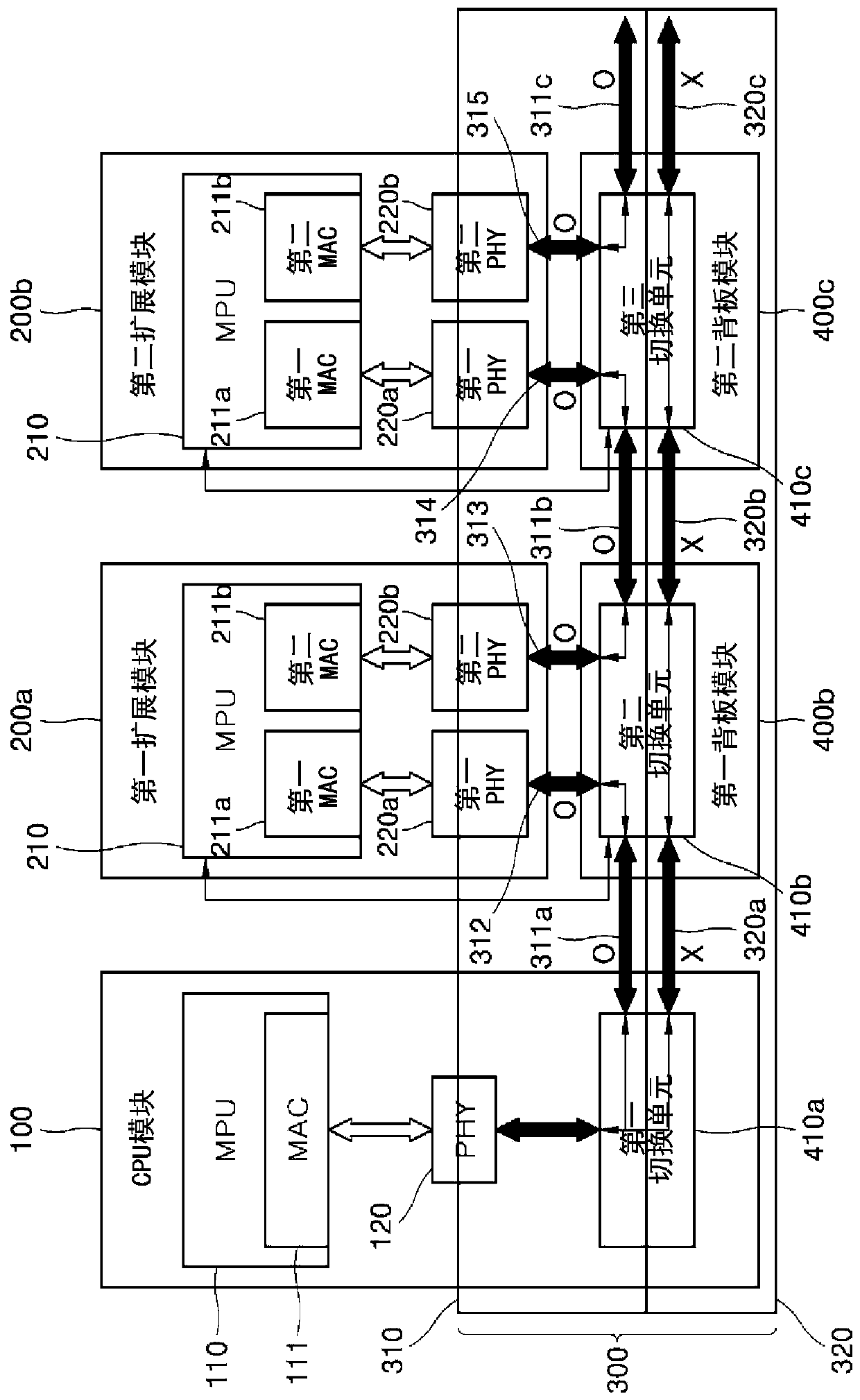

[0048] Below, will refer to Figure 3 to Figure 5 The hot-swap device of the Ethernet-based PLC backplane according to some embodiments of the present invention is described. It should be noted that, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com