Heat dissipation type film coating machine for paper printing

A heat-dissipating, laminating machine technology, used in printing presses, general parts of printing machinery, printing and other directions, can solve problems such as time-consuming, high temperature of paper prints, and inability to take them in the first time, so as to facilitate replacement. Or repair, expand the heat dissipation area, and improve the effect of lamination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

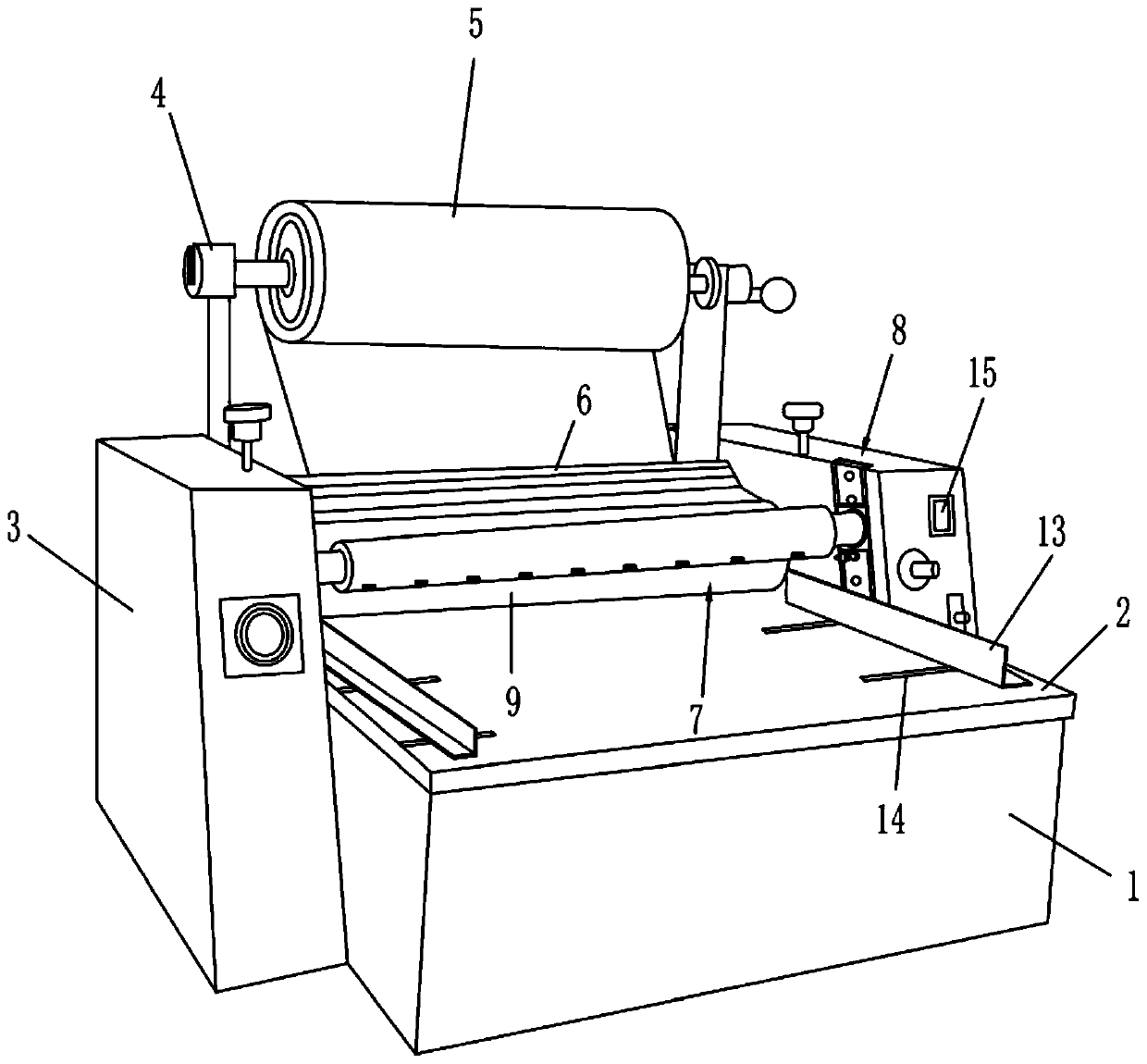

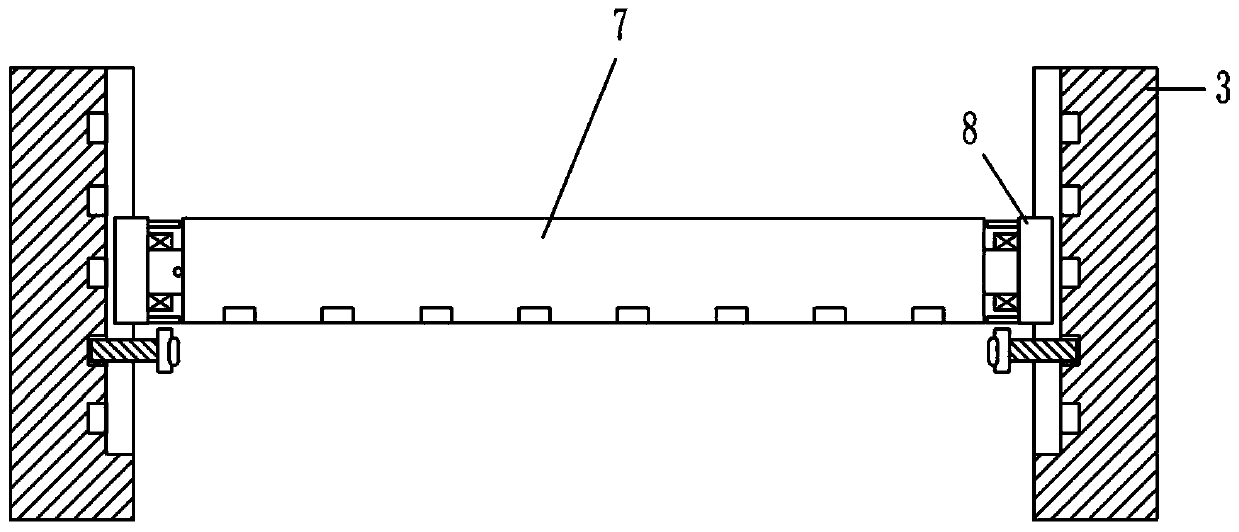

[0026] A heat-dissipating laminating machine for paper printing, such as Figure 1-6 As shown, it includes an equipment box 1, a film-coated board 2, a control box 3, a control rod 4, a film-coated belt 5, a film-coated device 6, a cooling part 7, a height adjustment part 8 and a film-coated wheel 9; the film-coated board 2 Fixed to the top of the equipment box 1; the control box 3 is fixed to the side of the equipment box 1; the control rod 4 is fixed to the side of the control box 3, and the coating belt 5 is connected to the control rod 4; the coating equipment 6 is fixed to the On the side of the control box 3, and communicated with the inside of the control box 3; the laminating wheel 9 is fixed to the laminating equipment 6, and is located above the laminating plate 2; the height adjustment part 8 is fixed on the side of the control box 3; the cooling part 7 is slidably connected with the height adjustment part 8;

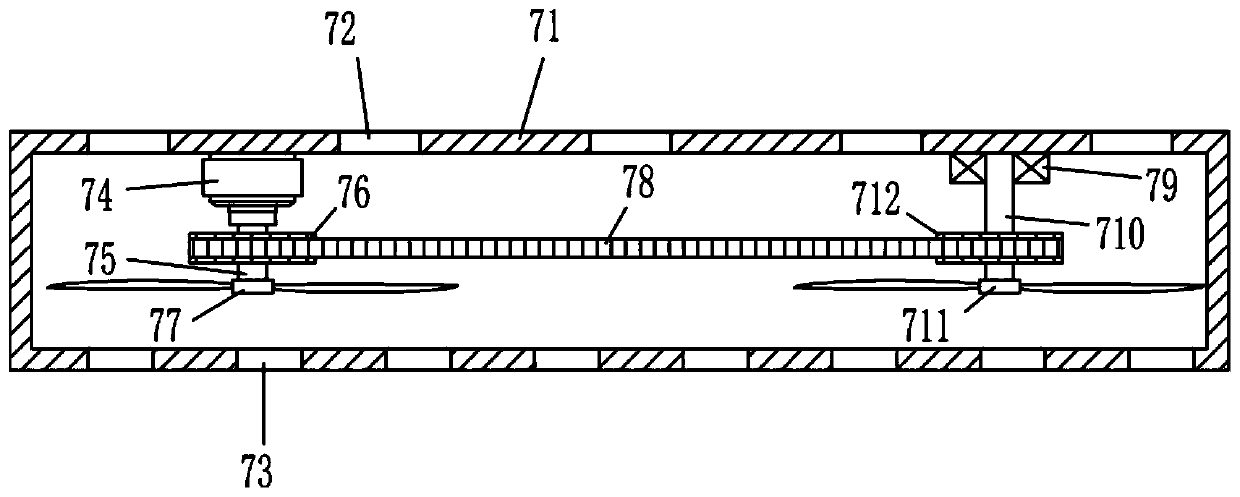

[0027] The cooling component 7 includes a mounting box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com