Waste metal pipeline cutting device in chimney of radioactive plant

A technology for scrap metal and pipe cutting, applied in the direction of pipe shearing device, shearing device, metal processing equipment, etc., to achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

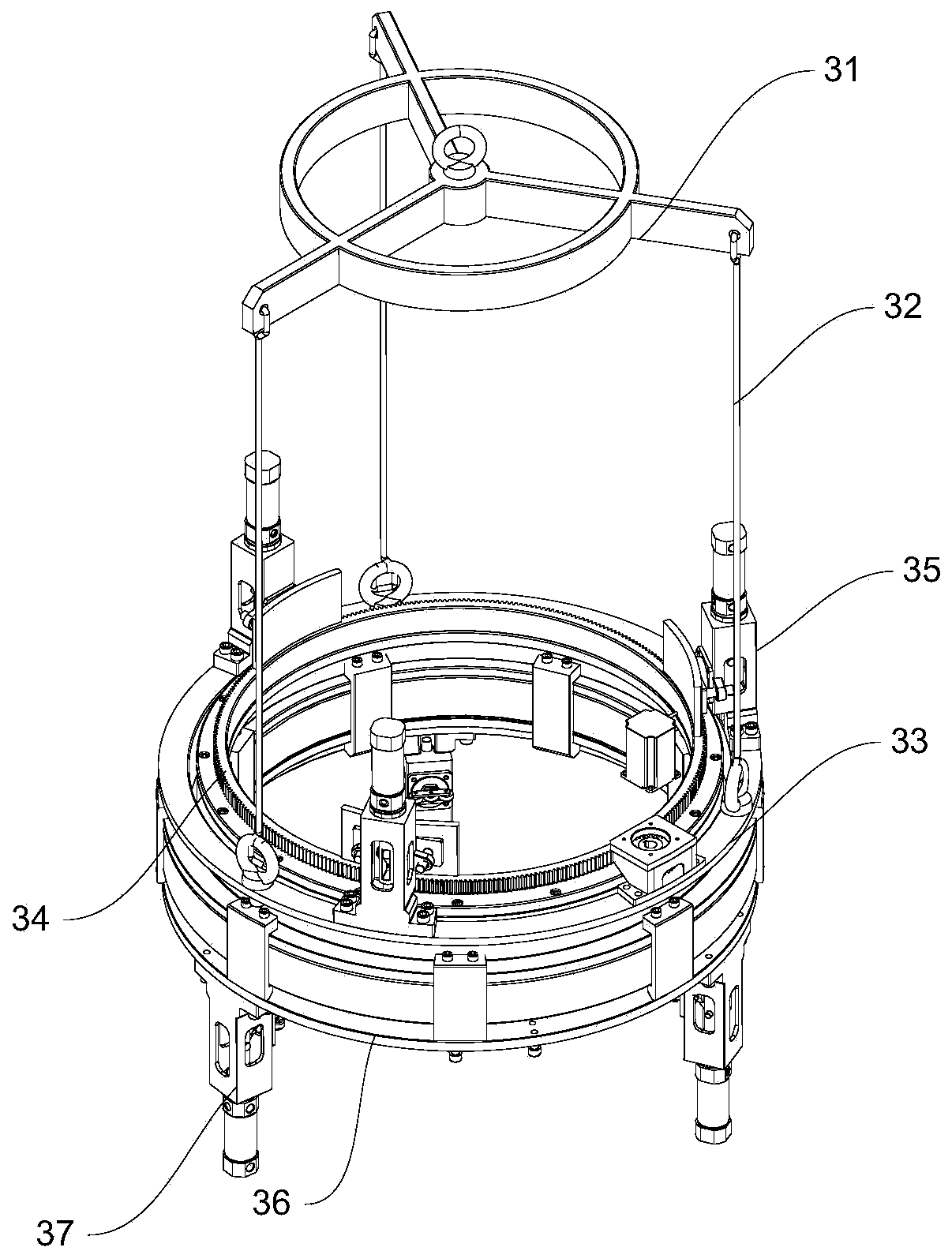

[0044] A cutting device for waste metal pipes inside the chimney of a radioactive factory building. In order to facilitate the cutting of vertical pipes by the pipe cutting device 37, the pipe cutting device 37 includes a fixed ring 33 on which a rotatable inner ring gear 34 is installed. The ring gear 34 is connected with the swivel ring 36, at least two clamping devices 35 for holding the chimney pipe are installed on the fixed ring 33, and at least one cutting device 37 for cutting the chimney pipe is installed on the rotating ring.

[0045] Wherein clamping device 35 can adopt present common clamping mechanism, clamps as hydraulic pressure / pneumatic / leading screw / rack retractable mechanism, because it is the prior art not repeating here, cutting device 37 can adopt cutting wheel 376, Mechanisms such as cutter and cutting disc are realized. The pipe cutting device 37 is set on the pipe, and after the clamping device 35 on the fixed ring 33 holds the fixed pipe tightly, the ...

Embodiment 2

[0047] A cutting device for waste metal pipes inside the chimney of a radioactive factory building. In order to facilitate the cutting of vertical pipes by the pipe cutting device 37, the pipe cutting device 37 includes a fixed ring 33 on which a rotatable inner ring gear 34 is installed. The ring gear 34 is connected with the swivel ring 36, at least two clamping devices 35 for holding the chimney pipe are installed on the fixed ring 33, and at least one cutting device 37 for cutting the chimney pipe is installed on the rotating ring.

[0048] Further, in order to facilitate the hanger of the pipe cutting device 37, the fixed ring 33 is connected to the hanger 31 through the sling 32, and the hanger 31 is connected to the steel rope of the hoist.

[0049] Further, in order to facilitate the clamping movement of the clamping device 35, the clamping device 35 includes a clamping bracket 351 fixed on the fixing ring 33, and a clamping disc 355 is installed on the clamping bracket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com