Liquid crystal display panel, manufacturing method thereof, and display device

A technology of liquid crystal display panel and manufacturing method, which is applied in the direction of instruments, nonlinear optics, optics, etc., which can solve the problems of missing electrodes, decreased transmittance, and decreased aperture ratio of pixel units, so as to achieve brightness and contrast and increase light leakage area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

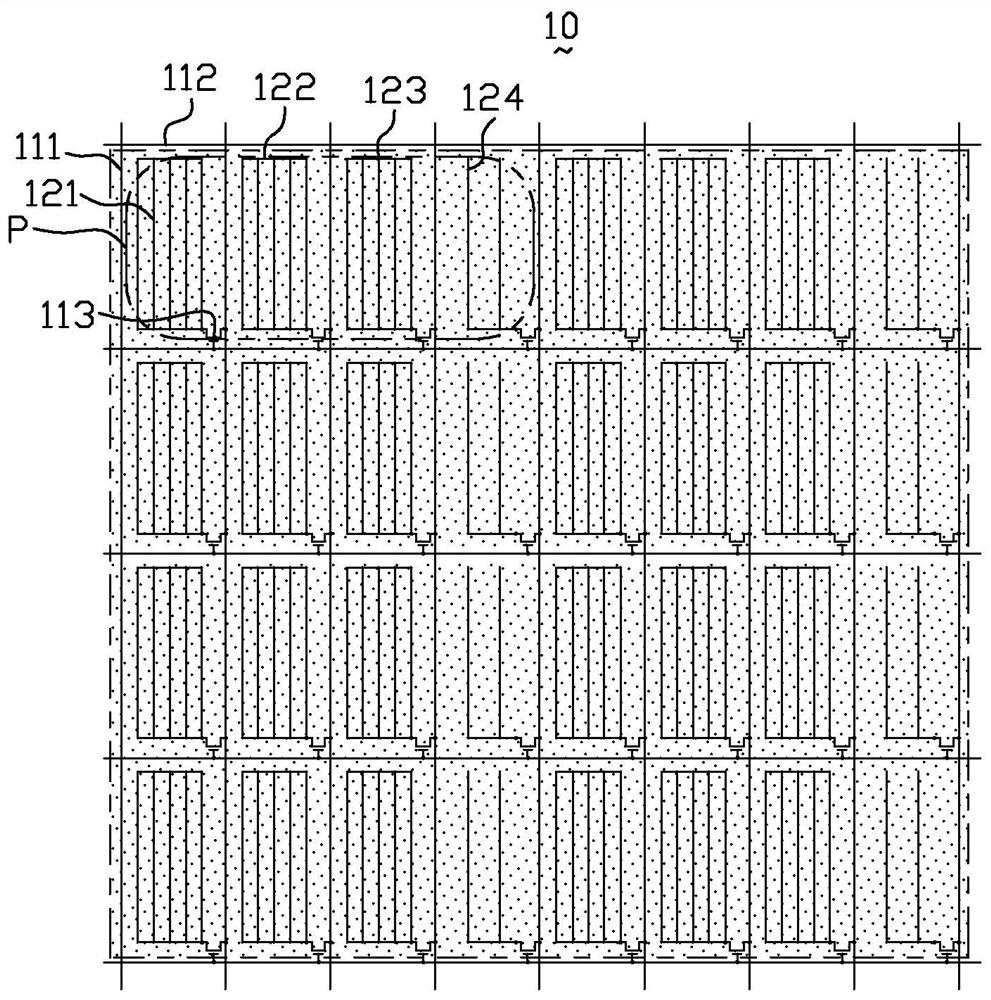

[0036] like figure 1 and figure 2 As shown, the liquid crystal display panel 100 provided in this embodiment includes an array substrate 10 , a color filter substrate 30 and a liquid crystal layer 20 sandwiched between the array substrate 10 and the color filter substrate 30 . The liquid crystal display panel 100 is provided with a plurality of pixel units P, and each pixel unit P includes a first area PA and a second area PB, and the first area PA is provided with a red sub-pixel electrode 121, a green sub-pixel electrode 122, a blue A sub-pixel electrode 123, the second area PB is provided with a white sub-pixel electrode 124, and each pixel unit P is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com