Contour processing error measuring device and method of hydraulic cone piston of excavator

A technology of contour processing and error measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low sensitivity, complex structure of optical measurement method, cumbersome measurement method, etc., and achieve the effect of reducing error and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

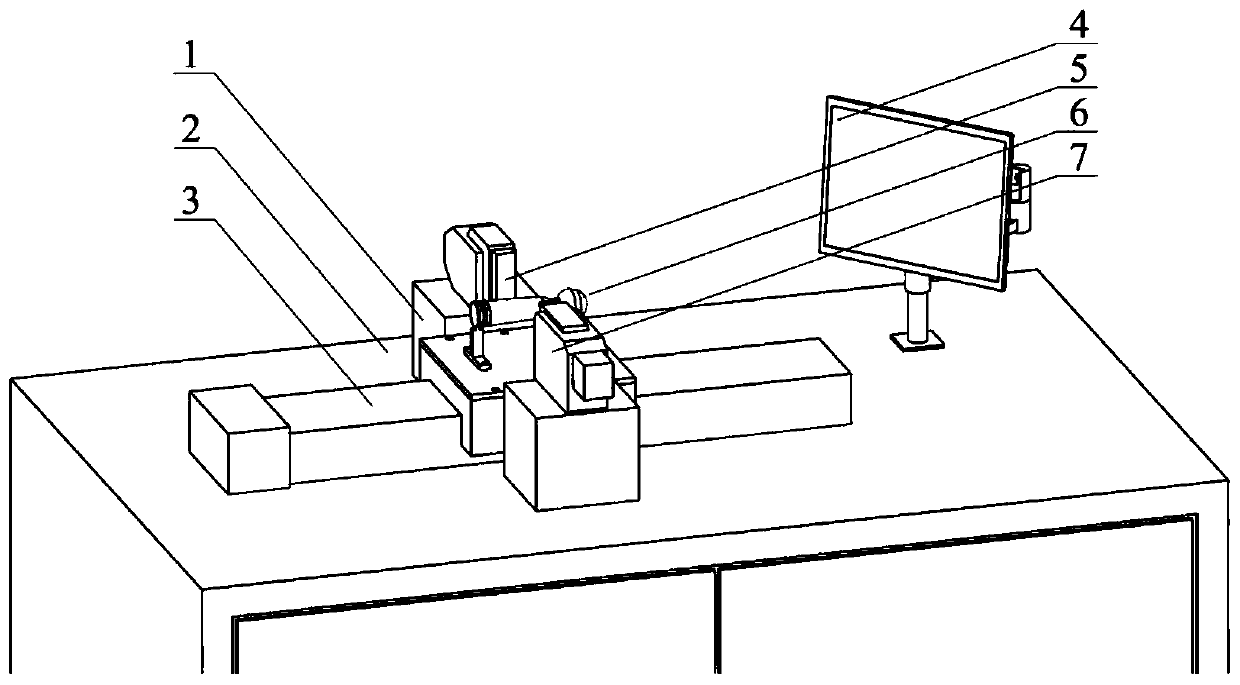

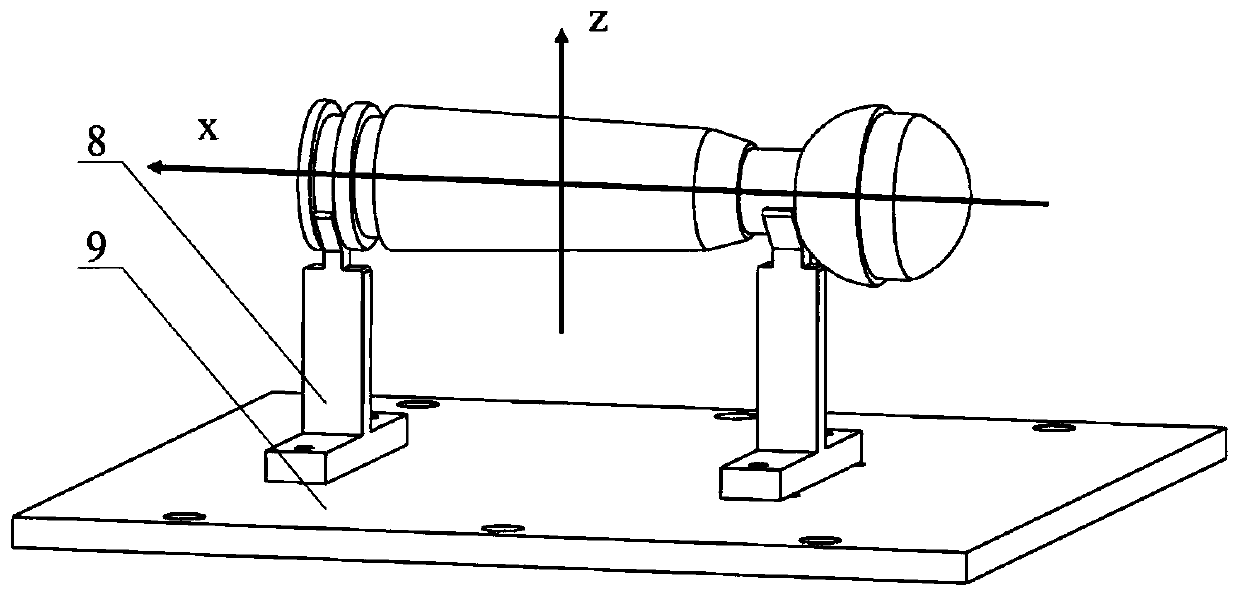

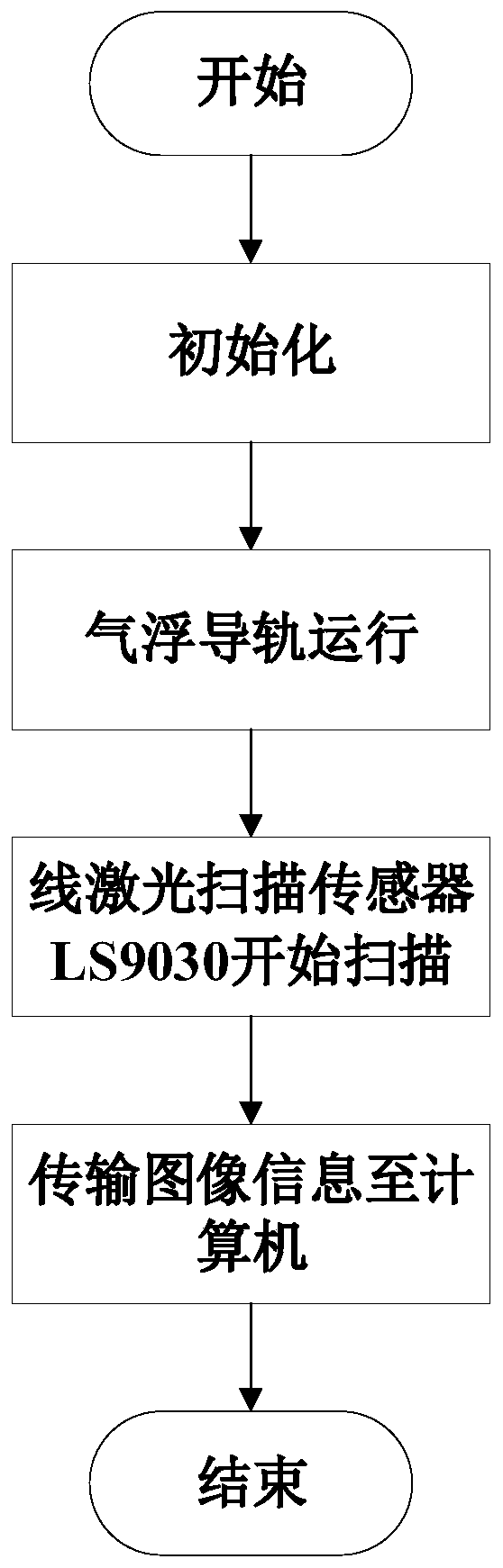

[0029] Such as figure 1 , figure 2 As shown, the fixed plate 9 is installed on the air flotation guide rail 3, the Y-shaped cone plunger is installed on the fixed plate to install the fixed module 8, the cone plunger 6 is placed on the Y-shaped cone plunger installation and fixed module 8, and the air flotation guide rail 3 There are two sensor fixing modules 1 on both sides. The transmitting end 7 of the line laser scanning sensor LS9030 and the receiving end 5 of the line laser scanning sensor LS9030 are installed above the sensor fixing module 1 respectively.

[0030] The line laser scanning sensor LS9030 transmitting end 7 and the line laser scanning sensor LS9030 receiving end 5 used in the present invention have high-speed sampling and tilt correction functions. The sensor measurement distance is 0.08 to 30 mm, and the measurement accuracy is 2 μm, which ensures high-precision measurement of parts . The straightness of the air bearing guide rail 3 is 0.2 μm, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com