Circular section pressure pipe annular anti-throwing limiting device and method thereof

A technology of pressure pipelines and restricting devices, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as the inability to accurately predict the direction of slamming, and achieve large market application and promotion value, convenient use, and excellent structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the examples of the present invention will be described in detail below in conjunction with the accompanying drawings in the examples of the present invention.

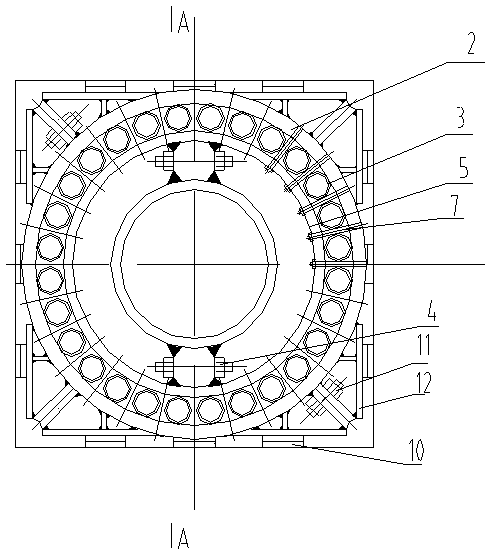

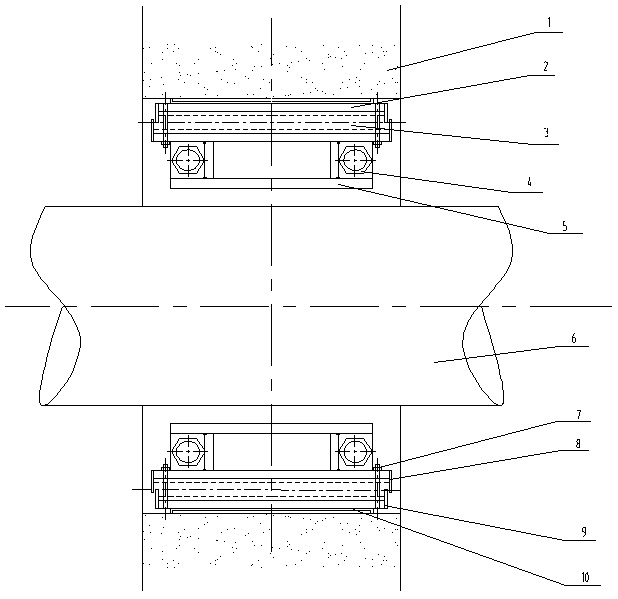

[0025] A ring-shaped anti-swing limiting device for pressure pipes with circular cross-sections, comprising a ring sleeve, which includes an inner ring 5 and an outer ring 2, the outer ring 2 is sleeved outside the inner ring 5, and a gap between the inner ring 5 and the outer ring 2 is formed Annular chamber.

[0026] A circle of flattened energy-absorbing columns 3 is arranged in the annular chamber, and the flattened energy-absorbing pillars 3 are close to the cavity wall of the annular chamber. An elongated energy-absorbing rod 7 is arranged between adjacent flattened energy-absorbing pillars 3 and stretched. One end of the long energy-absorbing rod 7 is fixed to the inner ring 5 and the other end is fixed to the outer ring 2. A first annular guard plate 8 is installed at both axial e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com