Butterfly valve of intermediate-pressure cylinder of steam turbine

A technology of steam turbine and medium pressure cylinder, which is applied in the field of butterfly valve of steam turbine medium pressure cylinder, can solve the problems of occupying additional space, high investment, complex system, etc., and achieves the effect of saving land occupation and investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

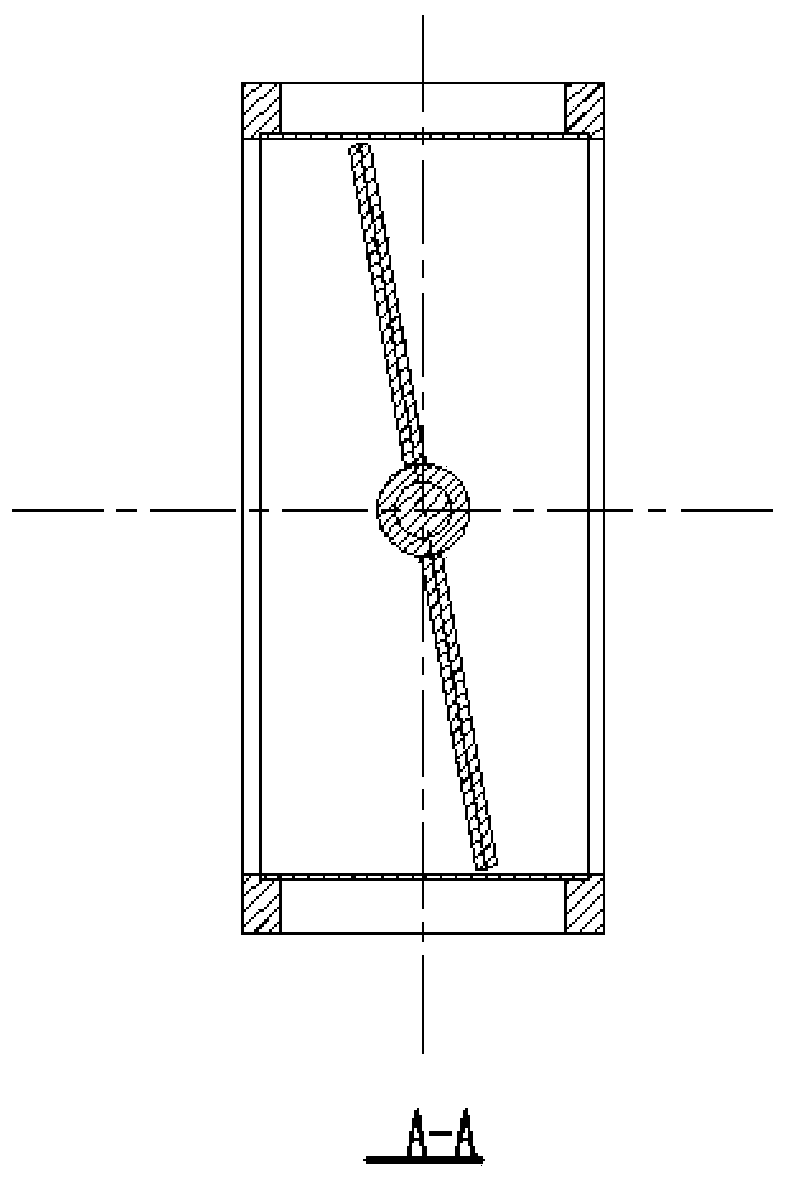

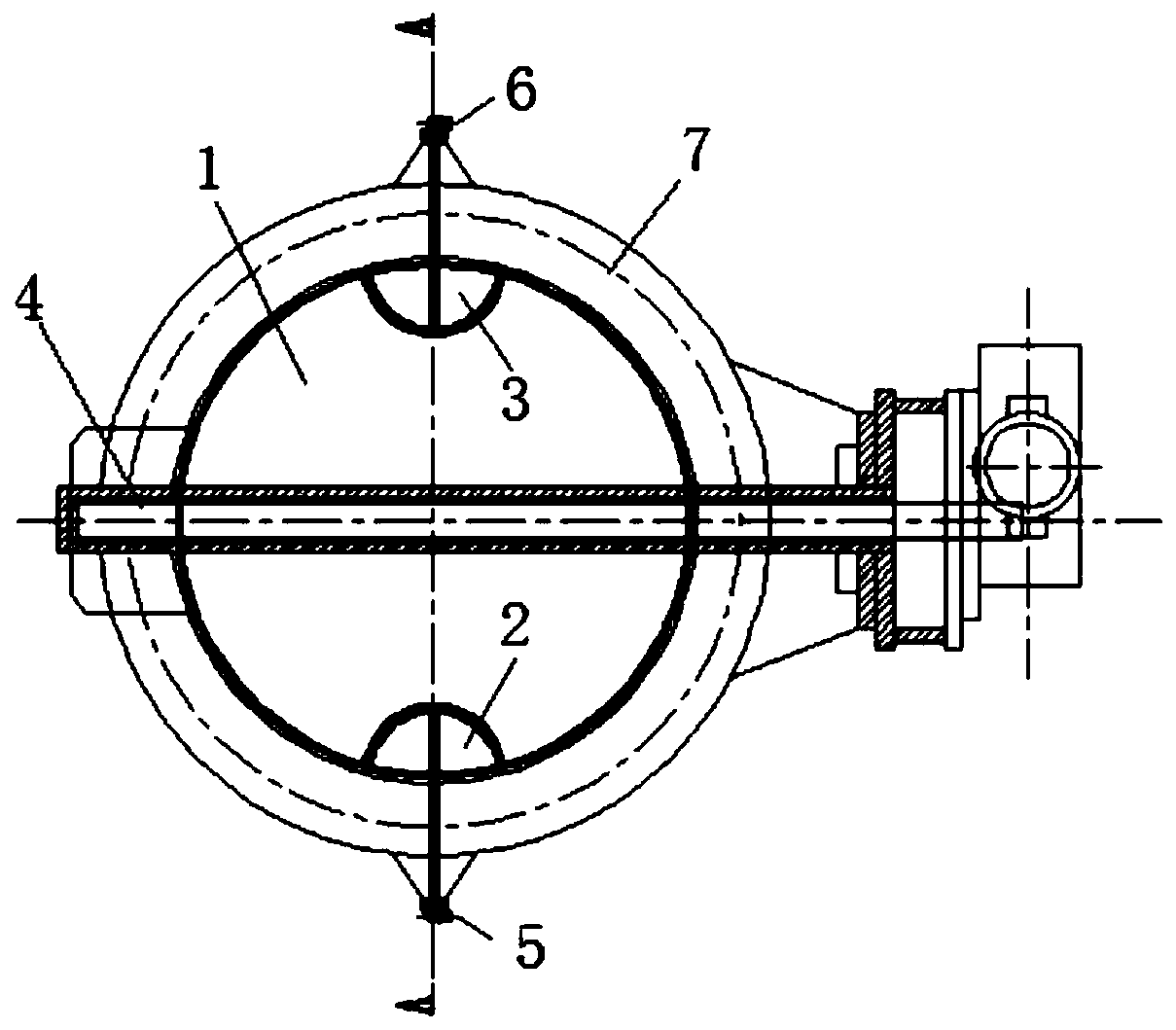

[0028] like image 3 and Figure 4 As shown, the butterfly valve of the steam turbine medium pressure cylinder of the present invention includes a valve body, a rotating shaft and an electric actuator for driving the rotating shaft, and is also provided with a valve disc 1 adapted to the outlet of the medium pressure cylinder. The valve disc 1 is installed through the rotating shaft 4 On the valve body at the outlet of the medium pressure cylinder, two small valve discs are arranged on the sealing surface of the valve disc 1, which are respectively the small valve disc 2 and the small valve disc 3. The sealing surface means that when both the valve disc and the small valve disc are closed, they are in a plane and close the section of the medium pressure cylinder.

[0029] The two small discs are installed symmetrically on both sides of the rotating shaft, and the rotating shafts of the two small discs are set perpendicular to the rotating shaft of the butterfly valve. The val...

Embodiment 2

[0032] Optionally, in this example, a small valve disc inscribed with the valve disc is installed at both ends of the rotating shaft of the butterfly valve disc in the medium-pressure cylinder of the steam turbine. The rotating shaft of the valve disc is perpendicular to the axis of the small disc. Turn on to adjust the intake steam flow into the low-pressure cylinder to meet and maintain the minimum flow for the safe operation of the low-pressure cylinder. For ease of installation and adjustment of the inlet steam flow.

[0033] like Figure 5 As shown, the plane shape of the small valve disc is approximately semicircular, and the two ends of the small valve disc in contact with the valve disc should avoid acute angles. The size of the added small disc is determined according to the steam inlet flow rate. 3% to 5% of the disc flow area, the structure of the small disc shaft is the same as that of the butterfly valve.

[0034] The working process is as follows:

[0035] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com