Tile core veneer

A core board and corrugated core technology, applied in the field of core boards, can solve the problems that the side wall of the corrugated core has no effect, the corrugated core is easily deformed by force, and the insulation effect of the tile core board is poor, so as to achieve heat concentration, improve the insulation effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

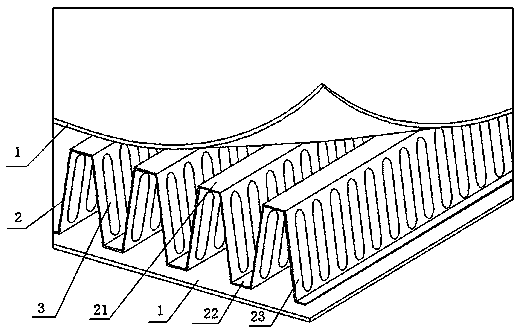

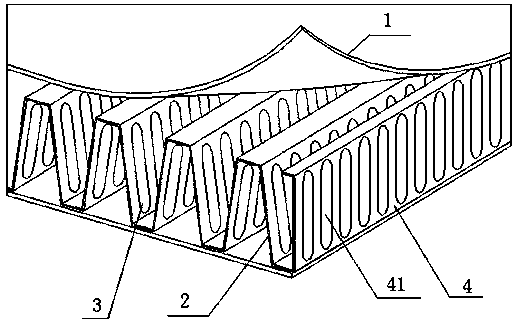

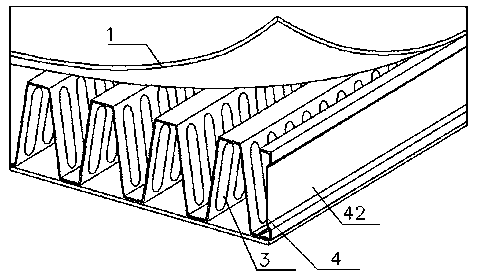

Image

Examples

Embodiment approach

[0031] S101: placing the corrugated core on the lower panel, and a solder is provided between the corrugated core and the lower panel;

[0032] S102: performing laser welding on the bottom surfaces of the corrugated core arranged at multiple intervals;

[0033] S103: After the corrugated core is pre-fixed on the lower panel, the upper panel is covered on the top surface of the corrugated core, and solder is also provided between the corrugated core and the upper panel;

[0034] S104: laser welding the corrugated core from the outside of the upper panel, so that the upper panel and the corrugated core are pre-fixed;

[0035] Among them, the density of laser welding on the top surface of the corrugated core is lower than that on the bottom surface, because the welding of the top surface is carried out from the outside of the upper panel, and the corrugated core and the upper panel are fixedly connected under the condition that the upper panel is not broken down by the laser.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com