Combined school uniform suitable for four seasons and manufacturing method thereof

A production method and combined technology, applied in clothing, clothing, clothing features, etc., can solve the problems of cold winter, unsuitable for all seasons, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

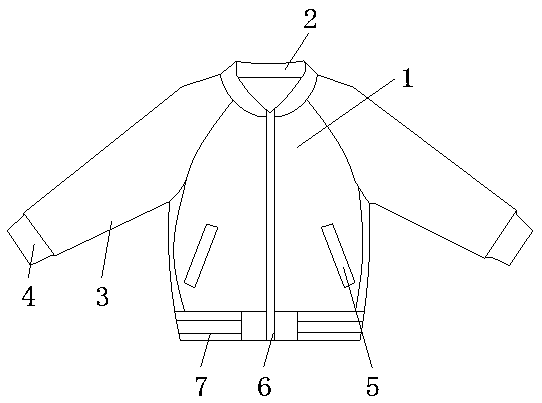

[0030] Making of school uniform: at first the school uniform body 1 made in advance is sewn on the school uniform body 1, then the school uniform sleeve 3 is sewn on both sides of the school uniform body 1, and the school uniform cuff 4 is sewn on the school uniform sleeve 3, Finally, the school uniform pocket 5, the connecting slide fastener 6 and the elastic band 7 are sewn on the clothing body, and the hidden slide fastener 13 is sewed on the inside of the school uniform body 1 and the school uniform sleeve 3;

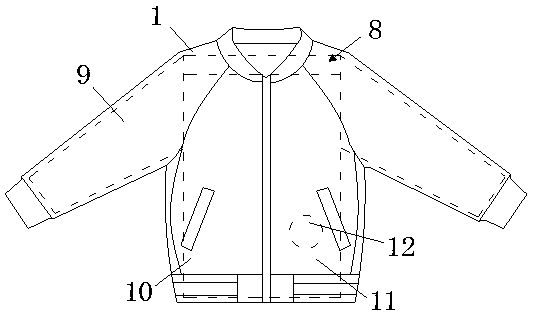

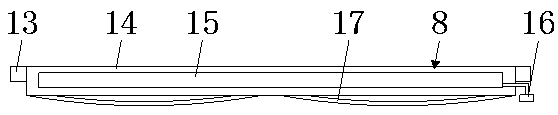

[0031] Insulation layer production: wrap the electric heating net 15 with cotton cloth, sew the electric heating net 15 inside the cotton cloth, connect the electric heating net 15 with wires, fix the wires, set the connecting joint 16 at one end of the wires, and finally wrap the electric heating net 15 on the cotton cloth Sewn hidden zipper 13 at the edge of the

[0032] Insulation layer installation: connect each insulation layer to the school uniform through hid...

Embodiment 2

[0034] Making of school uniform: at first the school uniform body 1 made in advance is sewn on the school uniform body 1, then the school uniform sleeve 3 is sewn on both sides of the school uniform body 1, and the school uniform cuff 4 is sewn on the school uniform sleeve 3, Finally, the school uniform pocket 5, the connecting slide fastener 6 and the elastic band 7 are sewn on the clothing body, and the hidden slide fastener 13 is sewed on the inside of the school uniform body 1 and the school uniform sleeve 3;

[0035] Insulation layer production: wrap the electric heating net 15 with cotton cloth, sew the electric heating net 15 inside the cotton cloth, connect the electric heating net 15 with wires, fix the wires, set the connecting joint 16 at one end of the wires, and finally wrap the electric heating net 15 on the cotton cloth The hidden zipper 13 is sewn at the edge; the material of the electric heating net 15 is iron-chromium-aluminum, nickel-chromium electric heating...

Embodiment 3

[0038] Making of school uniform: at first the school uniform body 1 made in advance is sewn on the school uniform body 1, then the school uniform sleeve 3 is sewn on both sides of the school uniform body 1, and the school uniform cuff 4 is sewn on the school uniform sleeve 3, Finally, the school uniform pocket 5, connecting zipper 6 and elastic band 7 are sewn on the clothes body, and the hidden zipper 13 is sewed on the inside of the school uniform body 1 and the school uniform sleeve 3, and the school uniform pocket 5 is reserved with a wire hole, and the clothes made of cotton;

[0039]Insulation layer production: wrap the electric heating net 15 with cotton cloth, sew the electric heating net 15 inside the cotton cloth, connect the electric heating net 15 with wires, fix the wires, set the connecting joint 16 at one end of the wires, and finally wrap the electric heating net 15 on the cotton cloth The hidden zipper 13 is sewn at the edge; the material of the electric heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com