A wheat dual-purpose fertilization seeder

A seeder and dual-purpose technology, applied in the field of wheat planting equipment, can solve problems such as increasing operating costs and reducing operating efficiency, and achieve the effects of improving operating efficiency, meeting sowing needs, and increasing wheat yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

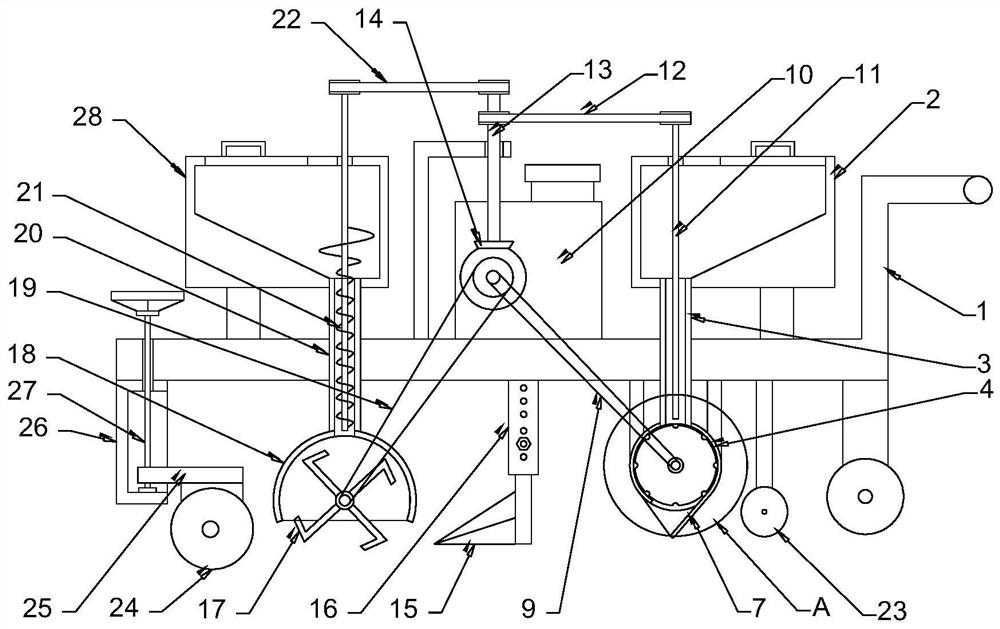

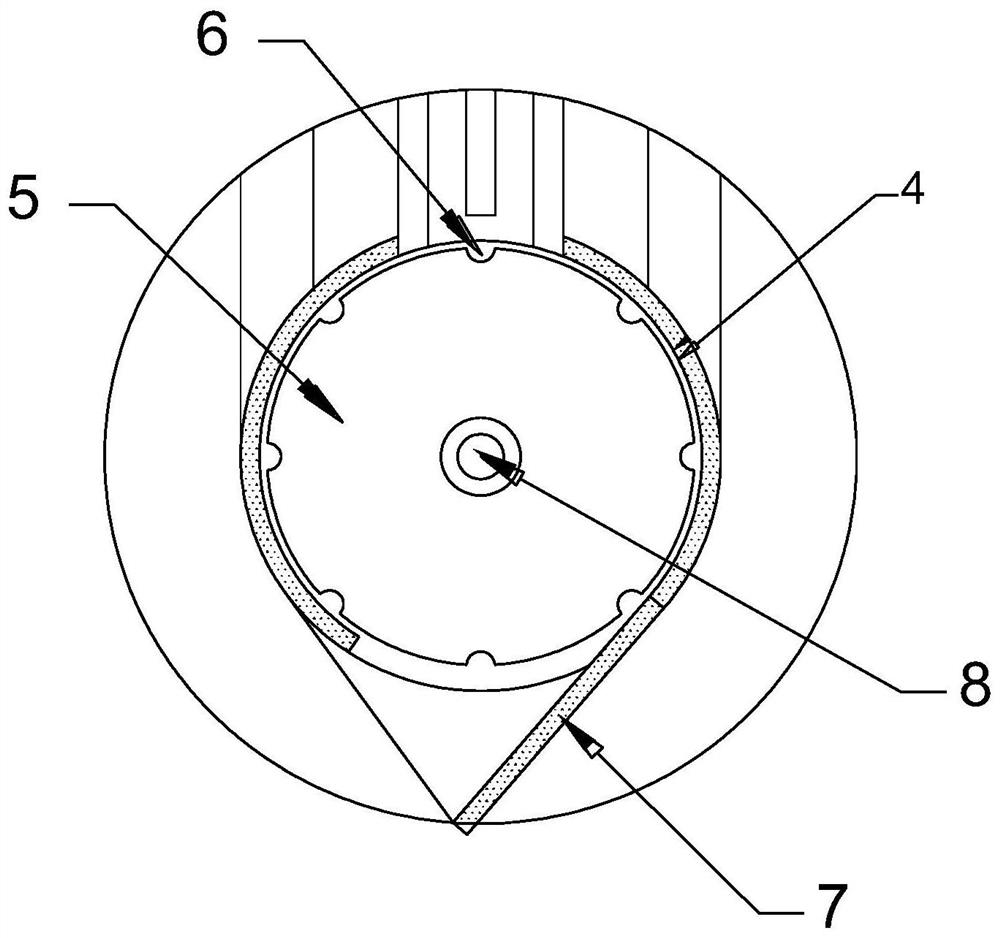

[0020] see Figure 1-3 , in the embodiment of the present invention, a wheat dual-purpose fertilizing and seeding machine includes a car body 1, a seed box 2 and a fertilizer box 28; the lower part of the seed box 2 is connected with a feeding tube 4 through a seed feeding pipe 3, and the feeding The barrel 4 is a cylinder arranged vertically; the lower material tray 5 is nested inside the lower material barrel 4, and the lower material tray 5 is slidingly connected with the inner wall of the lower material barrel 4; Distributed circular groove 6, feeding tray 5 is connected with the output shaft of diesel engine 10 through the first transmission belt 9, and diesel engine 10 drives feeding tray 5 to rotate clockwise; When wheat seeds fall into seed feeding pipe 3 and Entering in the circular groove 6 of the feeding tray 5, the feeding tray 5 drives the wheat seeds to rotate downward; Connected, the seed falls into the soil by the blanking cover 7.

[0021] The seed feeding p...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is that: the lower end of the fertilizer feeding pipe 20 is connected with a protective cover 18, the protective cover 18 is a cylindrical structure with an open lower end, and the protective cover 18 is nested with a scarifier roller 17, and the scarifier roller 17 is connected to the output shaft of the diesel engine 10 through the third transmission belt 19; the diesel engine 10 drives the loose soil roller 17 to rotate, and the soil is turned over, and at the same time, the fertilizer falling from the fertilizer feeding pipe 20 is fully mixed with the soil to ensure the soil fertilizer efficiency. Uniform, which in turn is conducive to the development of wheat seeds and increase yield.

[0027] The front end of the car body 1 is provided with a lifting direction wheel 24, the lifting direction wheel 24 is rotatably connected with a lifting frame 25, the upper end of the lifting frame 25 is nested with a chute fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com