Chipping arranging and pasting device and method

A paste device and arranging device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency, high labor costs for fragment pasting, etc., and achieve the effect of improving accuracy, good pasting effect, and avoiding random shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

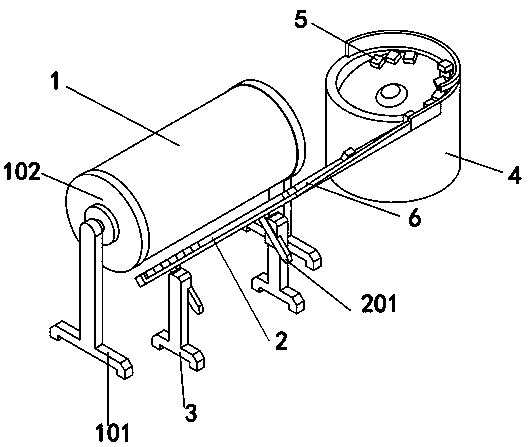

[0037] reference figure 1 , Figure 4 As shown, one embodiment of the present invention is a fragment arrangement and pasting device, which includes a linear guide rail 2. The linear guide rail 2 is provided with an opening for facing the cartridge case from the opening; the back of the linear guide rail 2 is provided with a sliding rail 201, wherein At least two slide rails 201 are installed on both sides of the back of the linear guide rail 2 to ensure stability.

[0038] The lower end of the linear guide 2 is provided with a first bracket 3, and the first bracket 3 is provided with a sliding groove 301. The sliding groove 301 is adapted to the sliding rail 201 and is used to push the linear guide in the sliding groove 301 by the sliding rail 201 2 Close to the shell 1; the linear guide rail 2 is provided with a fragment arranging device 4 on one side, the linear guide 2 is connected to the fragment arranging device 4, and the fragment arranging device 4 is used to fill the frag...

Embodiment 2

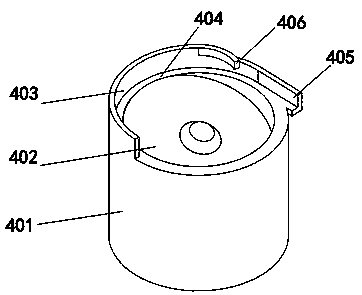

[0041] Based on the above embodiment, reference figure 2 As shown, another embodiment of the present invention is that in order to stabilize the output of fragments 5, the fragment arrangement device 4 includes a casing 401, and the casing 401 is provided with an inclined turntable 402, wherein the casing 401 is an existing cylinder The casing, in which the inclined turntable 402 is a centrifugal disk, in order to ensure that the fragment 5 will not accidentally leave the centrifugal disk during the centrifugation process, the gap between the inclined turntable 402 and the housing 401 does not exceed the thickness of the fragment 5; the inclined turntable There is a rotating shaft at the center of 402, and the rotating shaft is externally connected with a variable frequency motor, which is used to drive the inclined turntable 402 to rotate. The upper edge of the inclined turntable 402 is higher than the upper surface of the fragment slide 404 so as to facilitate the fragment 5 o...

Embodiment 3

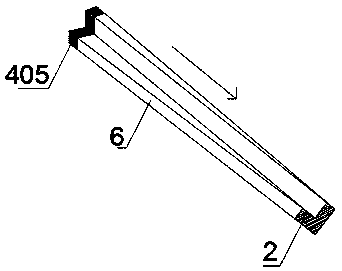

[0047] Based on the above embodiment, reference image 3 As shown, in order to adjust the posture of the fragment 5 entering the linear guide 2, a rotary guide 6 is provided between the linear guide 2 and the fragment arranging device 4. The rotary guide 6 is L-shaped, and the rotary guide 6 is gradually inclined from the head end to the end , The head end of the aforementioned rotating guide rail 6 is connected to the output end of the fragment arranging device 4, that is, the rotating guide rail 6 is connected to the end guide rail 405, and the end of the aforementioned rotating guide rail 6 is connected to the head end of the linear guide rail 2;

[0048] Among them, the fragment 5 is in a vertical state at the head end of the rotating guide rail 6, and the connecting mode of the rotating guide rail 6 and the end guide rail 405 is bolt connection, which makes the installation and disassembly of the rotating guide rail 6 easy and effectively improves the adaptability of the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com