Stranding machine with frequency division lay control function

A technology of a stranding machine and a frequency conversion controller, applied in the field of stranding machines, can solve the problems of affecting the use, the change of the traction tension cannot keep up with the speed of the take-up, and the strands are easy to bend and twist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

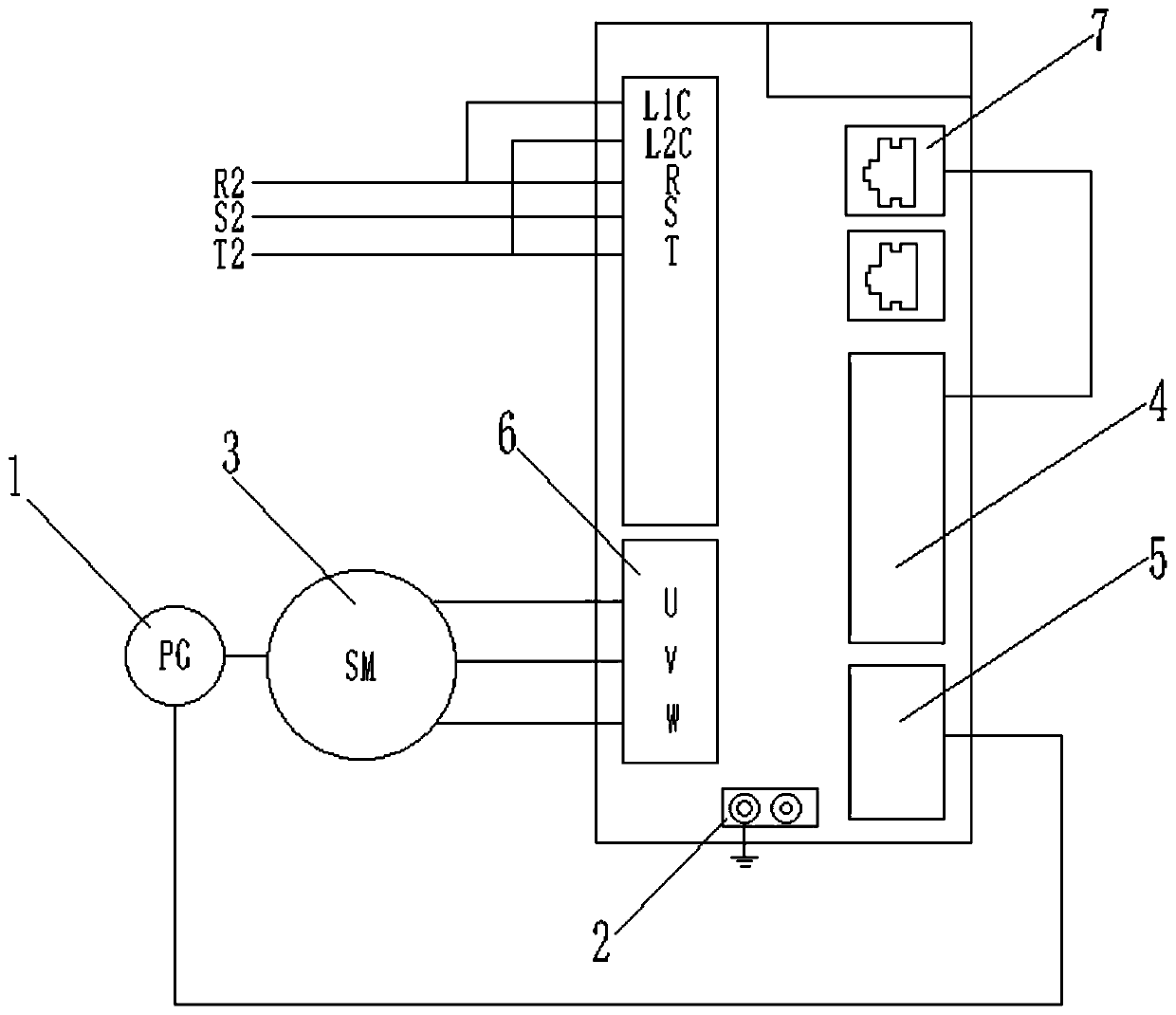

[0025] Now the present invention is further described in conjunction with description of drawings and embodiments:

[0026] A twisting machine for frequency division control of strand distance, comprising:

[0027] Drive winch bow frequency conversion controller: control the electronic gear ratio of the drive to control the speed ratio of the traction wheel motor and the winch drive motor;

[0028] Traction wheel motor: control the take-up tension of the traction wheel;

[0029] Bow drive motor: control the driving force of the rotating reel;

[0030] The frequency division control of the traction sheave motor and the winch drive motor by the drive winch frequency conversion controller, the frequency division control of the traction sheave motor and winch drive motor by the drive winch frequency conversion controller comprises the following steps:

[0031] (1) Input traction disc diameter, perimeter fine-tuning coefficient, main motor speed, winch speed, encoder resolution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com