Horizontal shear wave energy converter used for coarse grain material welding line detection

A horizontal shear wave and weld detection technology, which is applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve problems such as inability to detect weld seams, and achieve results Accurate, high detection accuracy, precise defect location effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

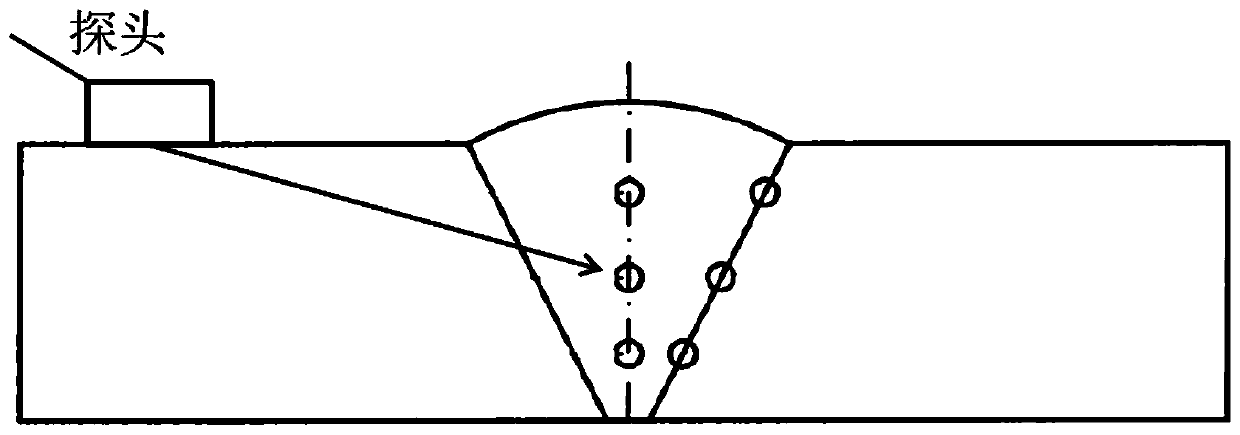

[0038] A horizontal shear wave transducer for the inspection of welds in coarse-grained materials such as figure 1 As shown, it includes a transducer body, a shell 1 for encapsulating the transducer body, a wedge 7 for carrying the transducer body, and a sound-absorbing layer 8 connected to the end of the wedge 7 . Wherein, the transducer body includes a permanent magnet 2 placed on the slope of the wedge 7, a magnetic induction coil 3 placed inside the permanent magnet 2, a magnetic induction sheet 4 attached to the lower surface of the magnetic induction coil 3, and a magnetic induction sheet 4 attached to the magnetic induction sheet 4. The epoxy resin coupling layer 6 on the lower surface, and the signal line connector 5 connected with the magnetic induction coil 3 .

[0039] The functions of each part in this embodiment are: the shell 1 is used to encapsulate the transducer body structure; the permanent magnet 2 is used to generate a horizontal bias magnetic field; wave ...

Embodiment 2

[0045] The main structure of this embodiment is the same as that of Embodiment 1, the difference lies in the design parameters of the wedge and the internal parts of the transducer body. In this embodiment, the angle between the inclined plane and the bottom surface of the wedge used is 60°; meanwhile, the width of the magnetic induction sheet 4 is 25 mm; the thickness of the magnetic induction sheet 4 is 0.2 mm, and the number of turns of the magnetic induction coil 3 is 40 turns , the signal line connector 5 matched with the magnetic induction coil 3 is an interface with 20 pins.

Embodiment 3

[0047] The main structure of this embodiment is the same as that of Embodiment 1, the difference lies in the design parameters of the wedge and the internal parts of the transducer body. In the present embodiment, the angle between the inclined plane and the bottom surface of the wedge used is 70°; meanwhile, the width of the magnetic induction sheet 4 is 50 mm; the thickness of the magnetic induction sheet 4 is 0.25 mm, and the number of turns of the magnetic induction coil 3 is 100 turns , the signal line connector 5 matched with the magnetic induction coil 3 is an interface with 40 pins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com