An easy-to-clean incinerator

A technology for incinerators and furnace bodies, applied in the field of incinerators, which can solve the problems of inconvenient fly ash cleaning, residues left, and small furnace openings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

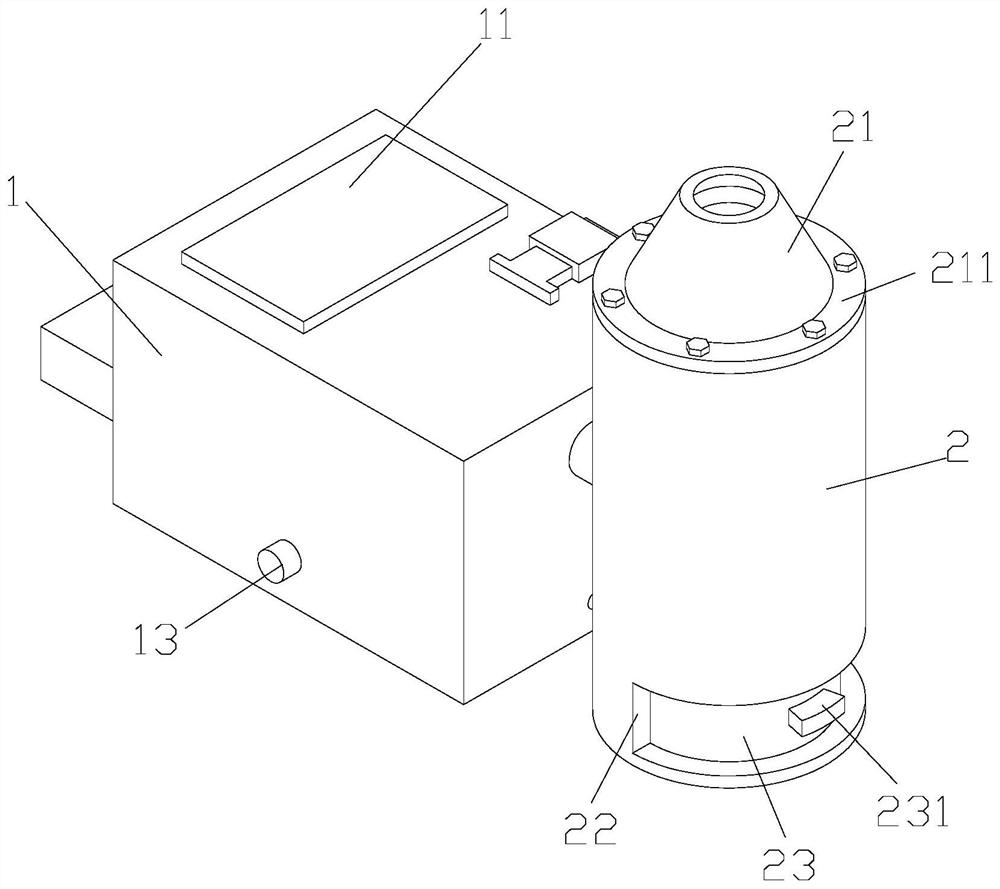

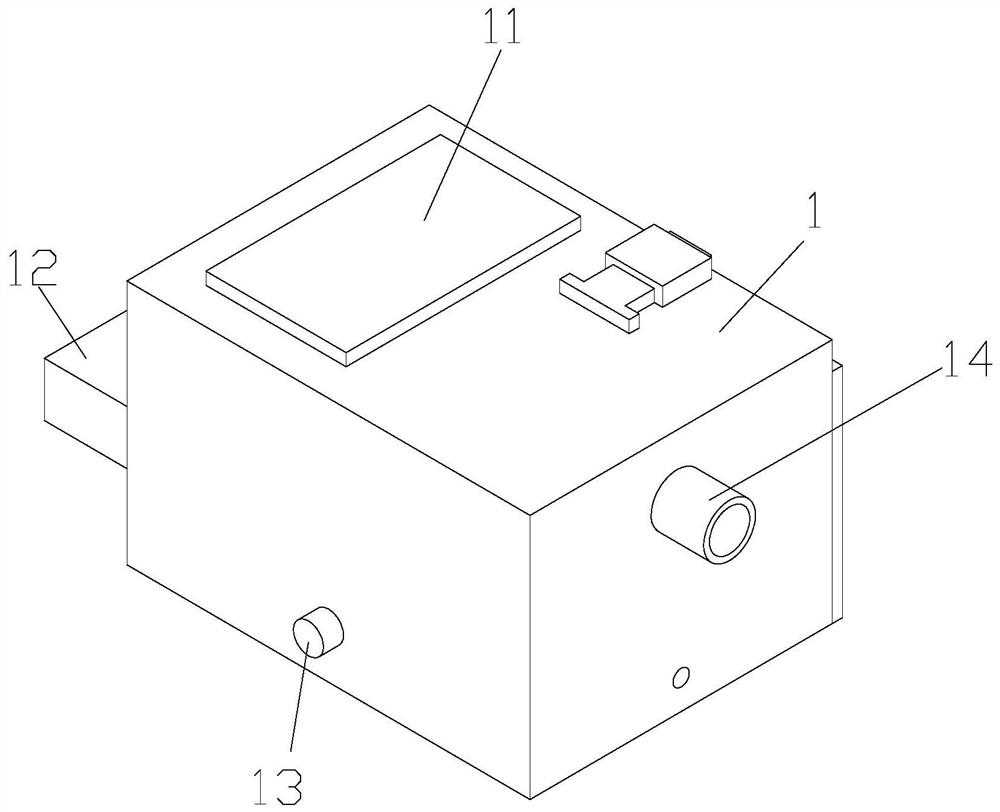

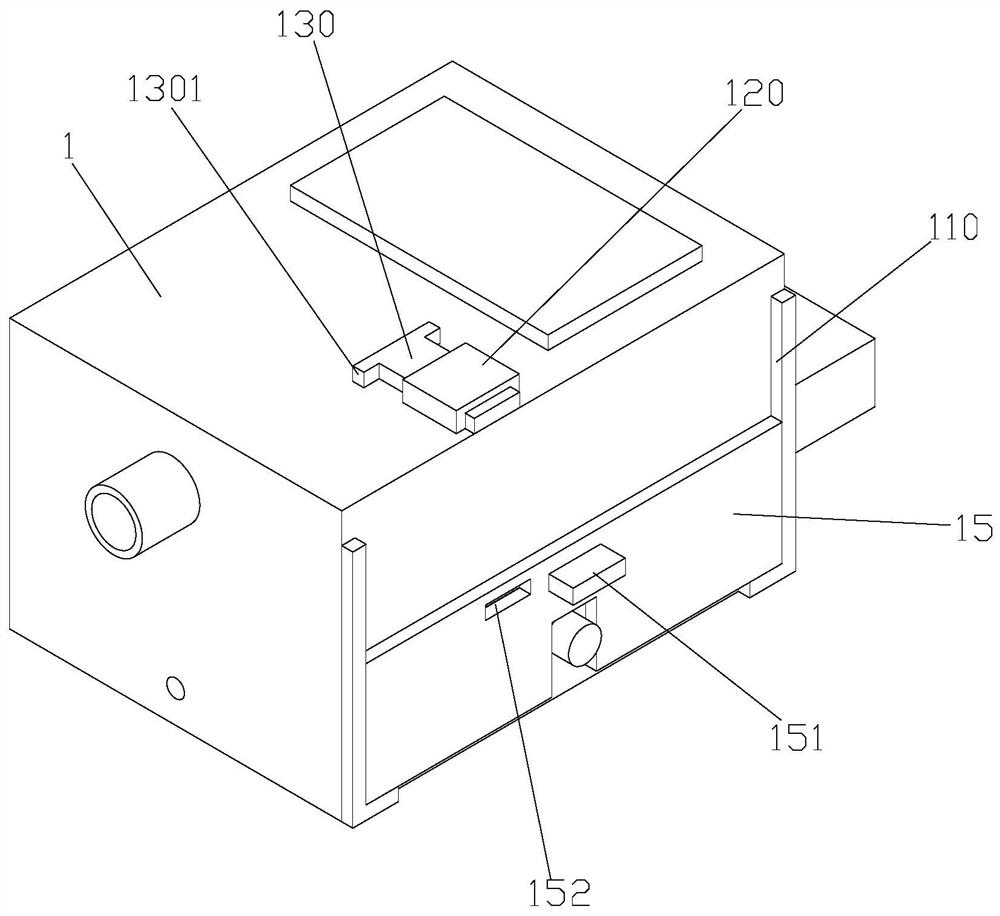

[0027] Such as Figure 1-14 As shown, a kind of incinerator that is easy to clean comprises a furnace body 1 and a chimney 2 located on one side of the furnace body 1, the top of the furnace body 1 is provided with a feed port, and the side wall of the furnace body 1 is provided with There is a discharge port, the top of the furnace body 1 is provided with a first sealing door 11 matching with the feed inlet, and the side wall of the furnace body 1 is provided with a second sealing door 11 matching with the discharge port. Door 15, one end of the first airtight door is hinged on the side wall of the incinerator, the first airtight door is provided with a lock catch, the other side of the furnace body 1 is provided with a connecting pipe 14, and the side wall of the chimney 2 is provided with The smoke outlet 24 matched with the connecting pipe 14, the furnace body and the chimney are connected through the connecting pipe, the chimney 2 is provided with a threaded rod 26, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com