Wheel-rail traction system of trailing suction hopper dredger

A technology for trailing suction dredgers and traction systems, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve problems such as low traction, damage to the drive motor, and slippage of the drive wheel , to achieve the effect of improving traction, reducing length and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

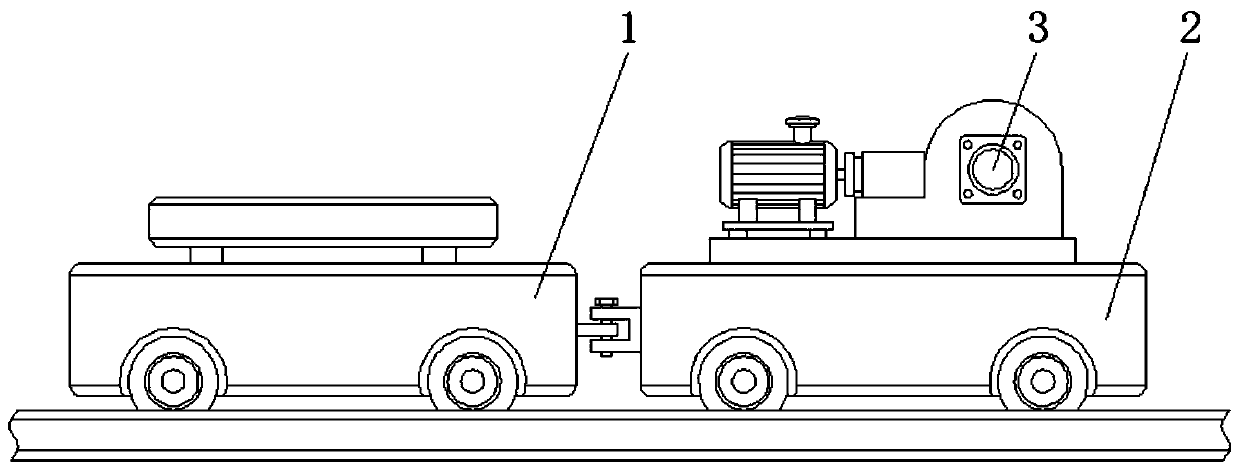

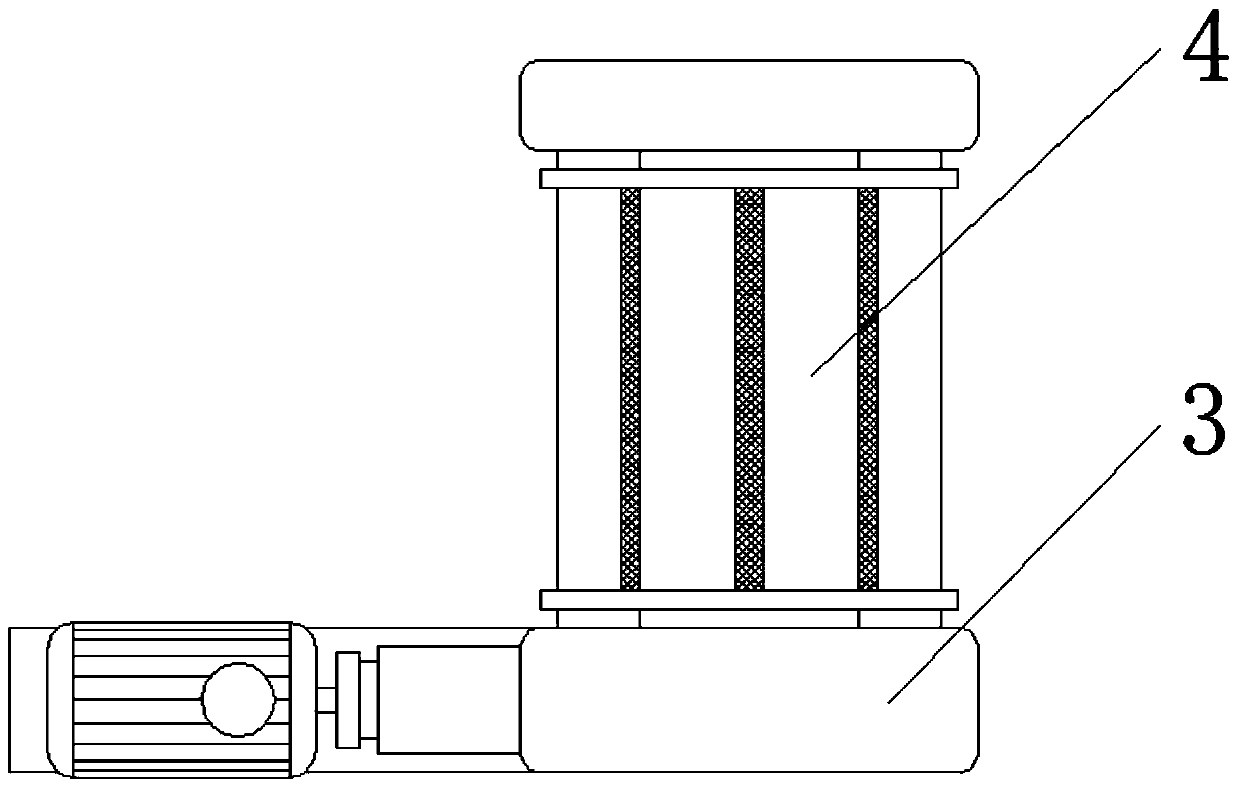

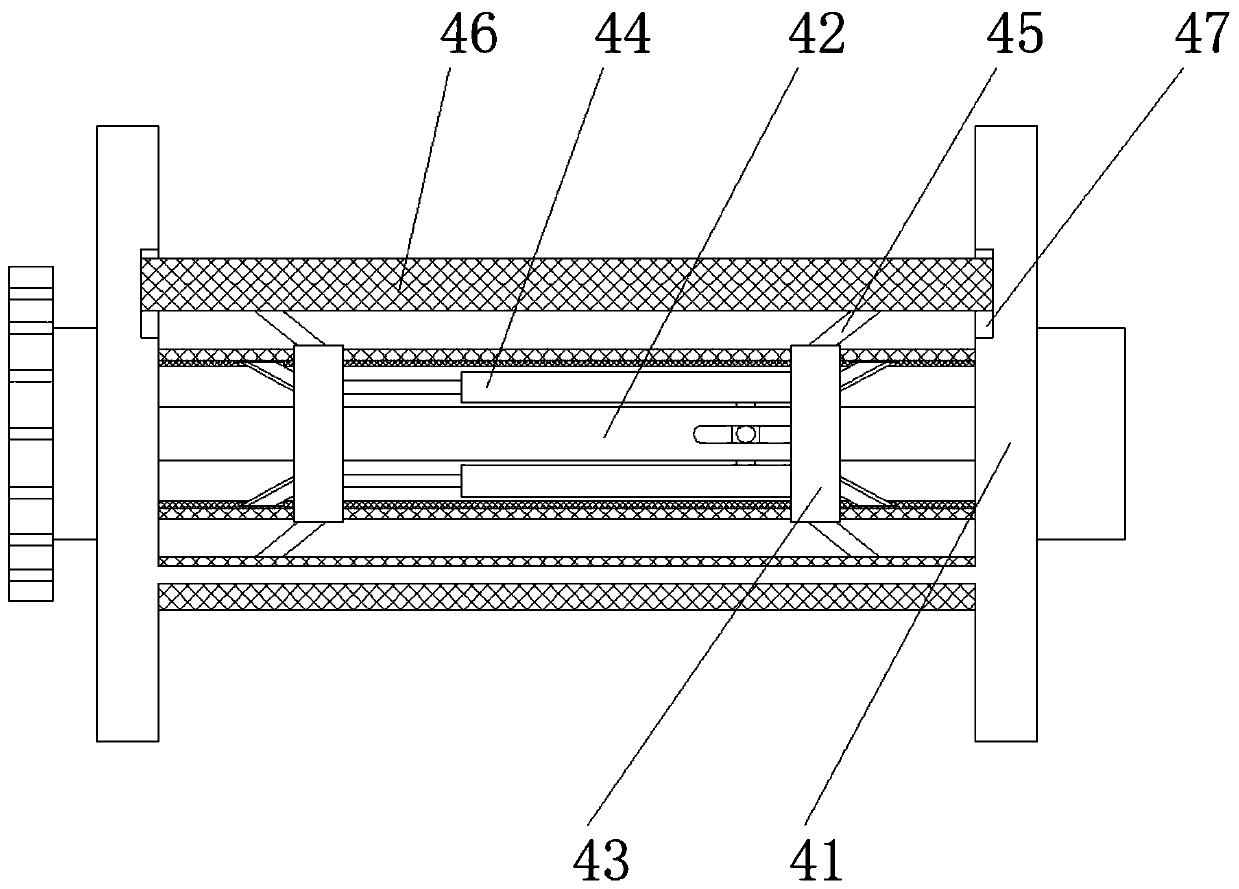

[0018] see Figure 1 to Figure 5 , the present invention provides a technical solution: a wheel-rail traction system of a trailing suction dredger, including a trolley 1, which itself is driven by a DC motor, and an electromagnetic clutch device is provided inside the trolley 1, which is convenient for automatic Self-switching under the two states of driving and dragging, and one side of the trolley 1 is connected with the tractor 2 through a bolt, and the top of the tractor 2 is installed with a winch 3, and the self-driving system of the trolley 1 and the winch 3 can work at the same time , reducing the probability of damage to the device due to excessive load when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com