Knitted pile carpet cutting machine

A cutting machine and carpet technology, which is used in textiles and papermaking, cutting of textile materials, metal processing, etc., can solve the problems of unsatisfactory cutting effect, unevenness, reducing the quality of velvet carpets, etc., and achieves good cutting effect. Good effect and fast cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

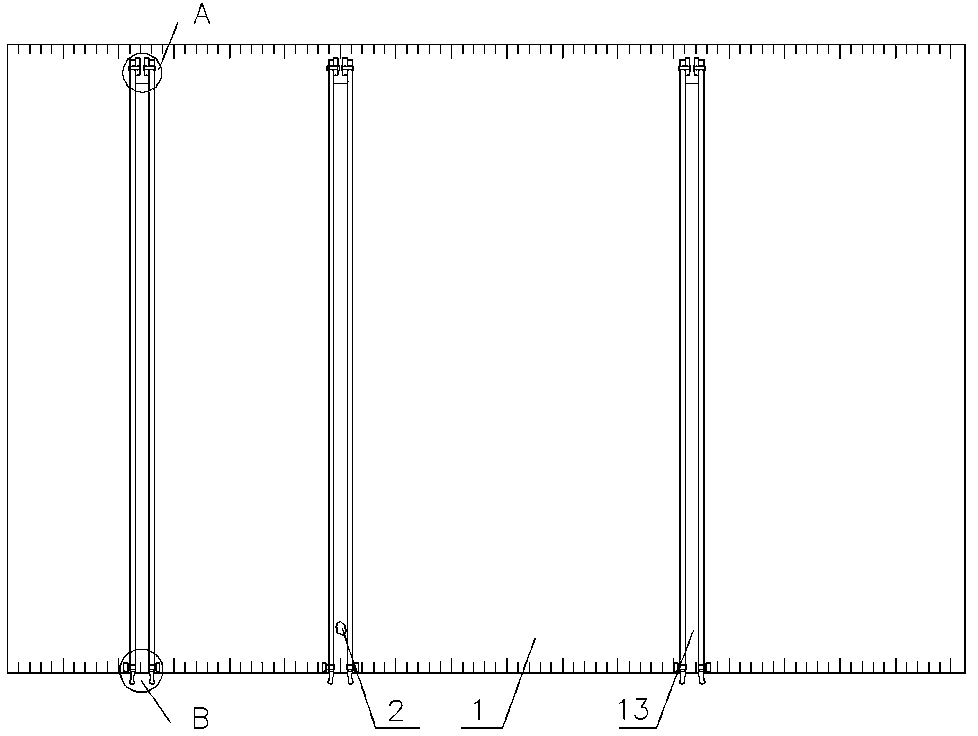

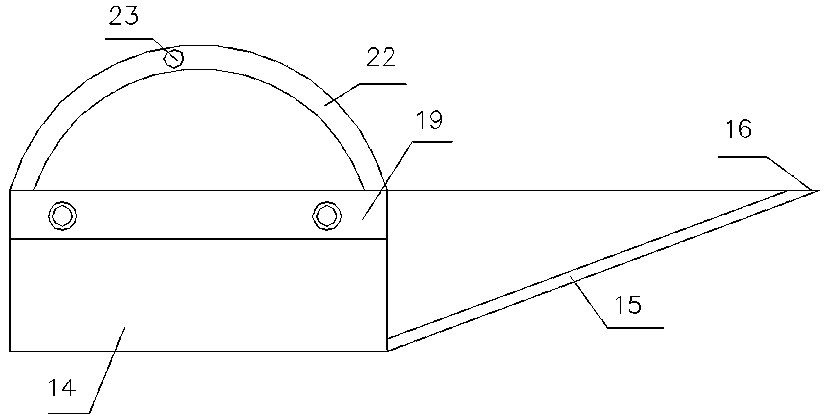

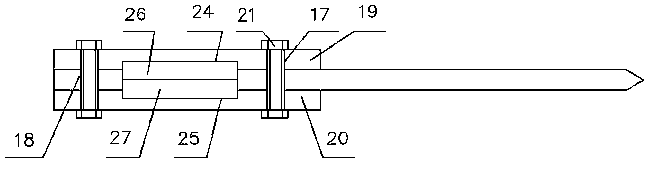

[0026] A kind of velvet carpet cutting machine, its composition comprises: a platform 1 with size scale, described platform has a group of cutting notch 2, the width of described cutting notch is 2mm, one of described cutting notch are parallel to each other, and the fixed front end of the platform is connected with a set of left vertical fixing plates 3 and a set of right vertical fixing plates 4, the left vertical fixing plate is set opposite to the right vertical fixing plate, and the left vertical fixing plate is arranged opposite to the right vertical fixing plate. The vertical fixing plate is located on the left side of the cutting notch, the right vertical fixing plate is located on the right side of the cutting notch, the left vertical fixing plate is riveted to the front end of the left pressing vertical plate 5, and the The right vertical fixed plate is riveted to the front end of the right pressure vertical plate 6, and the rear end of the platform is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com