Student canteen fluid food automatic distribution device

An automatic distribution and canteen technology, applied in the field of canteen utensils, can solve problems such as the inability to drink hot porridge, the porridge is easy to cool quickly, and the separation of soup and rice. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

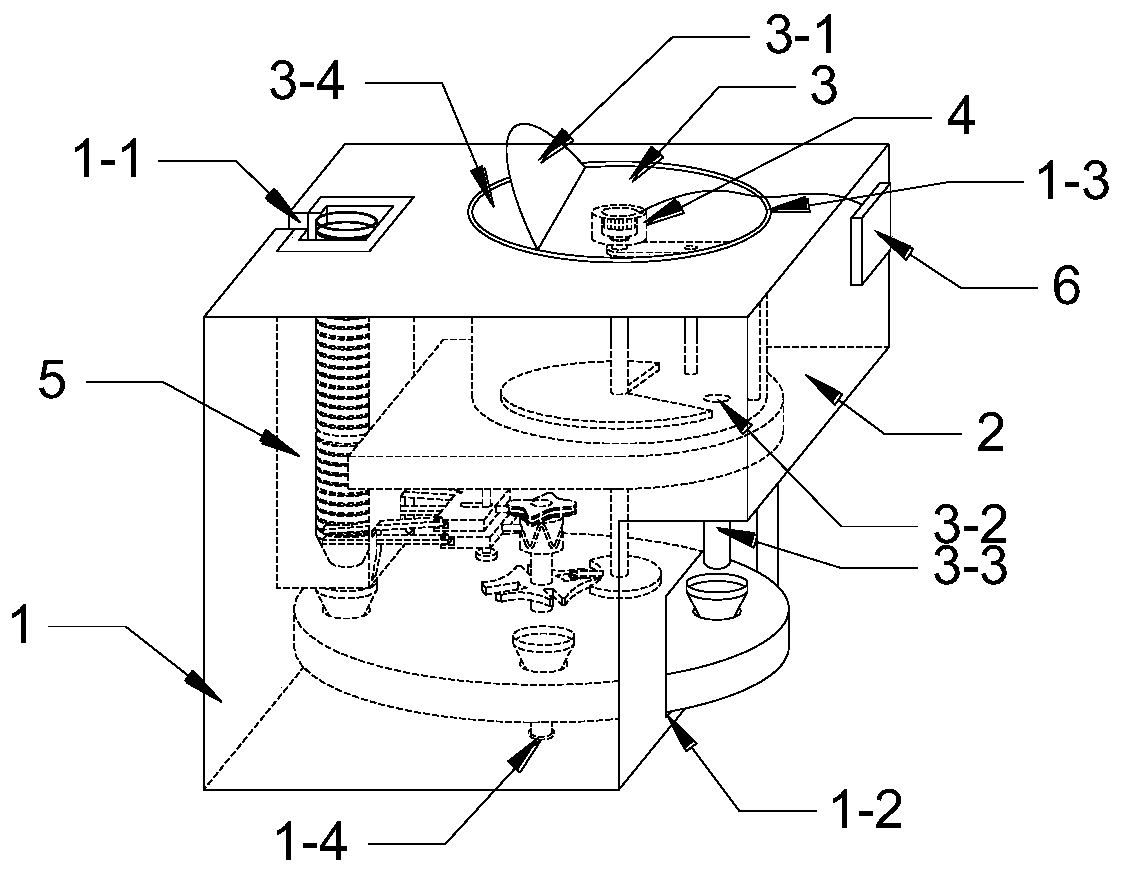

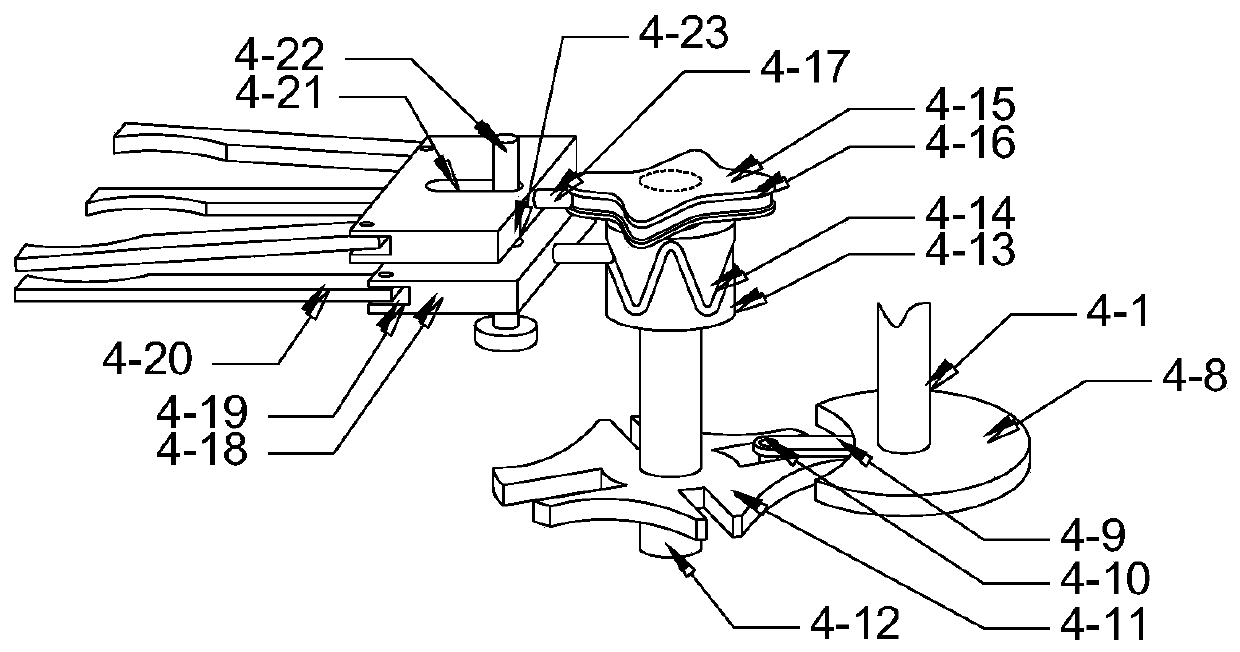

[0019] Attached below Figure 1~5 The present invention is described in detail below.

[0020] Such as Figure 1~5As shown, the present invention includes an L-shaped main box 1, a support frame 2, a storage tank 3, an automatic porridge outlet device, a bowl rack 5, a card reader 6 and a first turntable 7, and the inside wall of the L-shaped main box 1 The upper left end is fixedly connected with a bowl rack 5 and the left end of the bowl rack 5 is provided with the third open slot 5-2 communicated with the first open slot 1-1 of the left end of the L-shaped main box 1 to facilitate the placement of the bowl. 5. A support frame 2 is fixedly connected in the middle of the right end, and the upper end of the support frame 2 is fixedly connected to the storage tank 3. The upper end of the storage tank 3 is inserted into the first through hole 1-3 at the upper right end of the L-shaped main box 1 and its The upper left end is provided with an arc-shaped through hole 3-4, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com