Spherical manned cabin submersible cabin cover

A technology for manned cabins and hatch covers, applied in ship hatches/hatches, ship parts, ships, etc., can solve the problems of inability to ensure uniform distribution of pressing force, deterioration of thread self-locking, and easy wear of transmission threads. , to achieve the effect of reducing labor consumption, improving strength, and uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

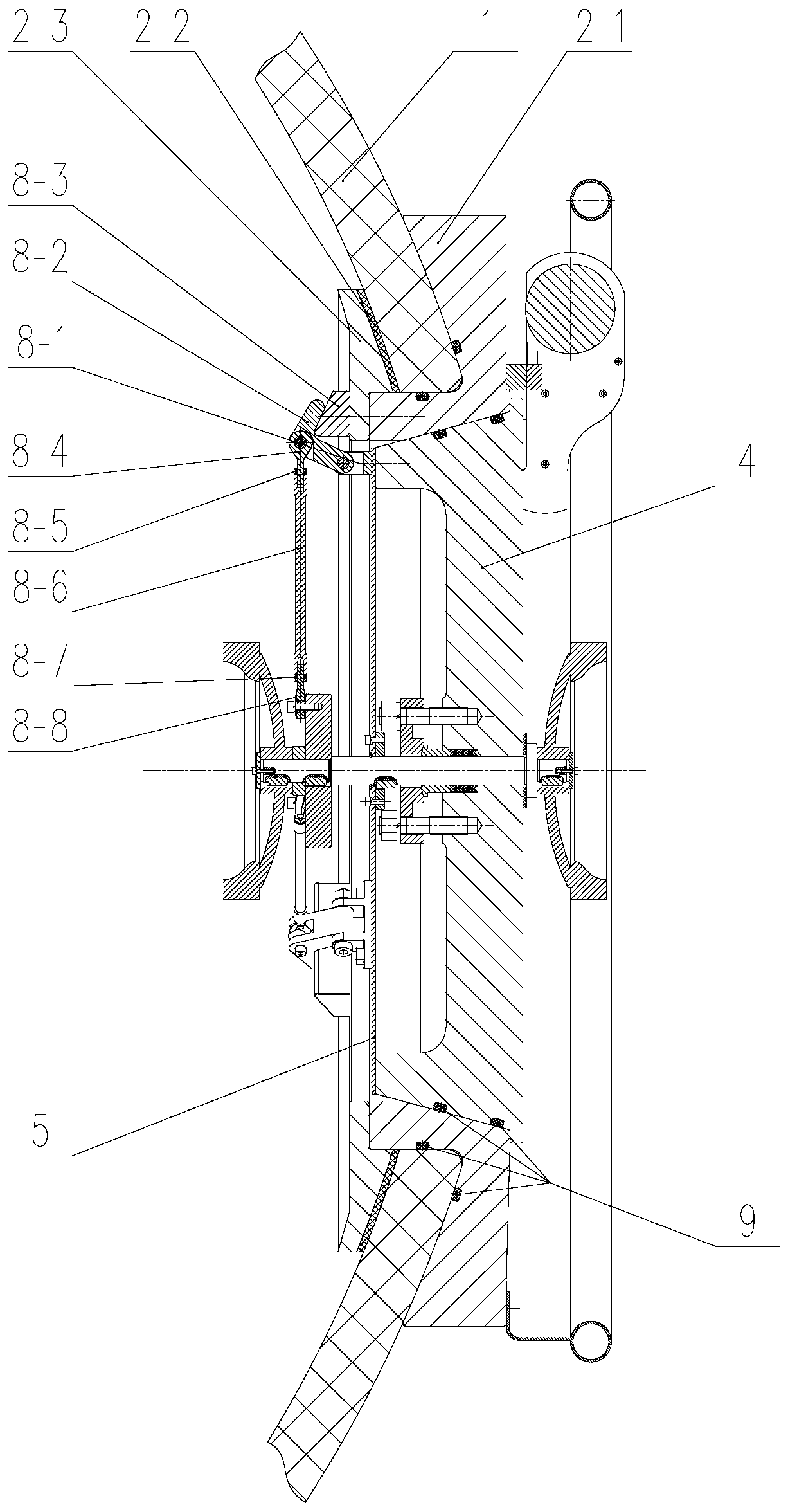

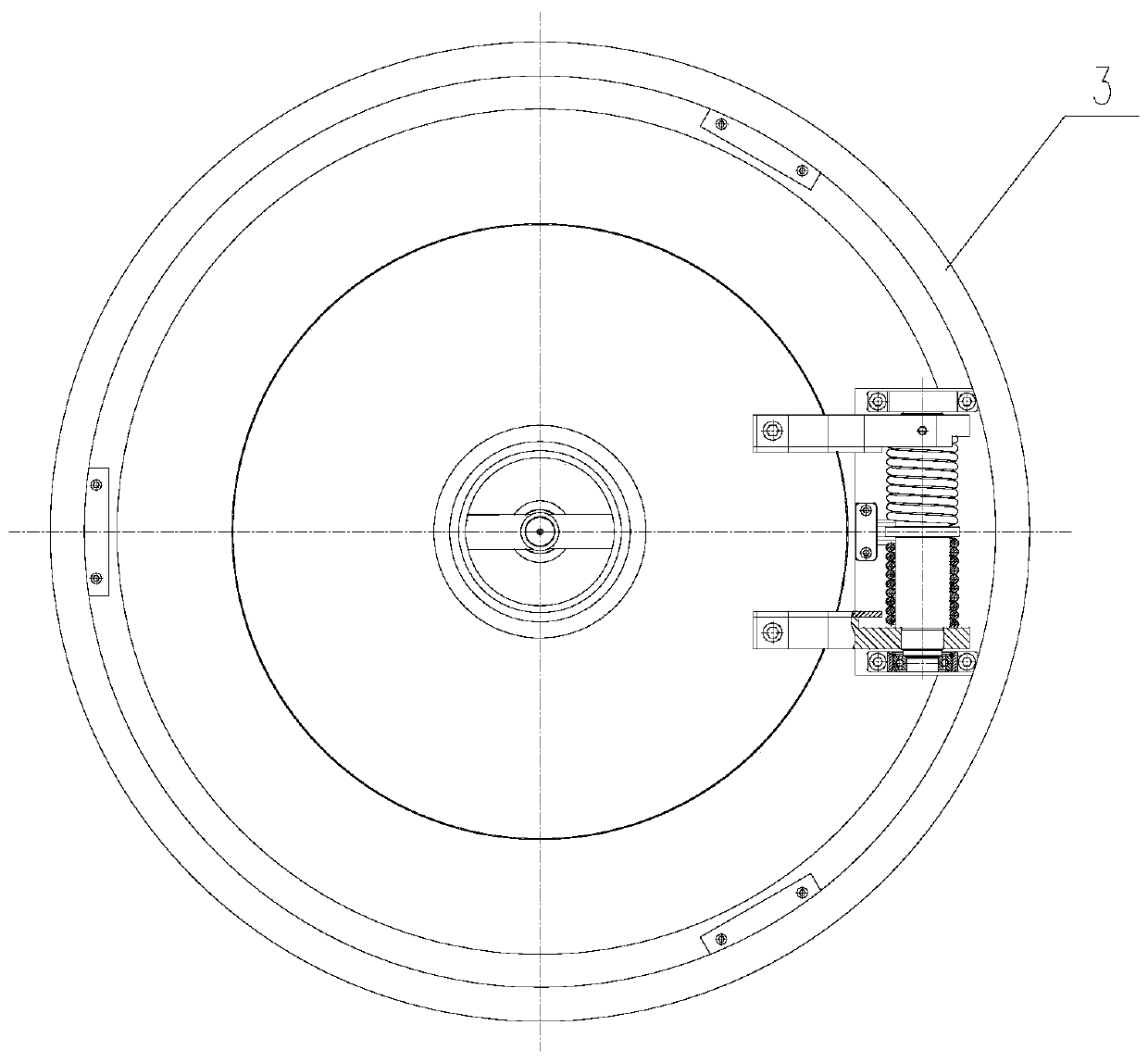

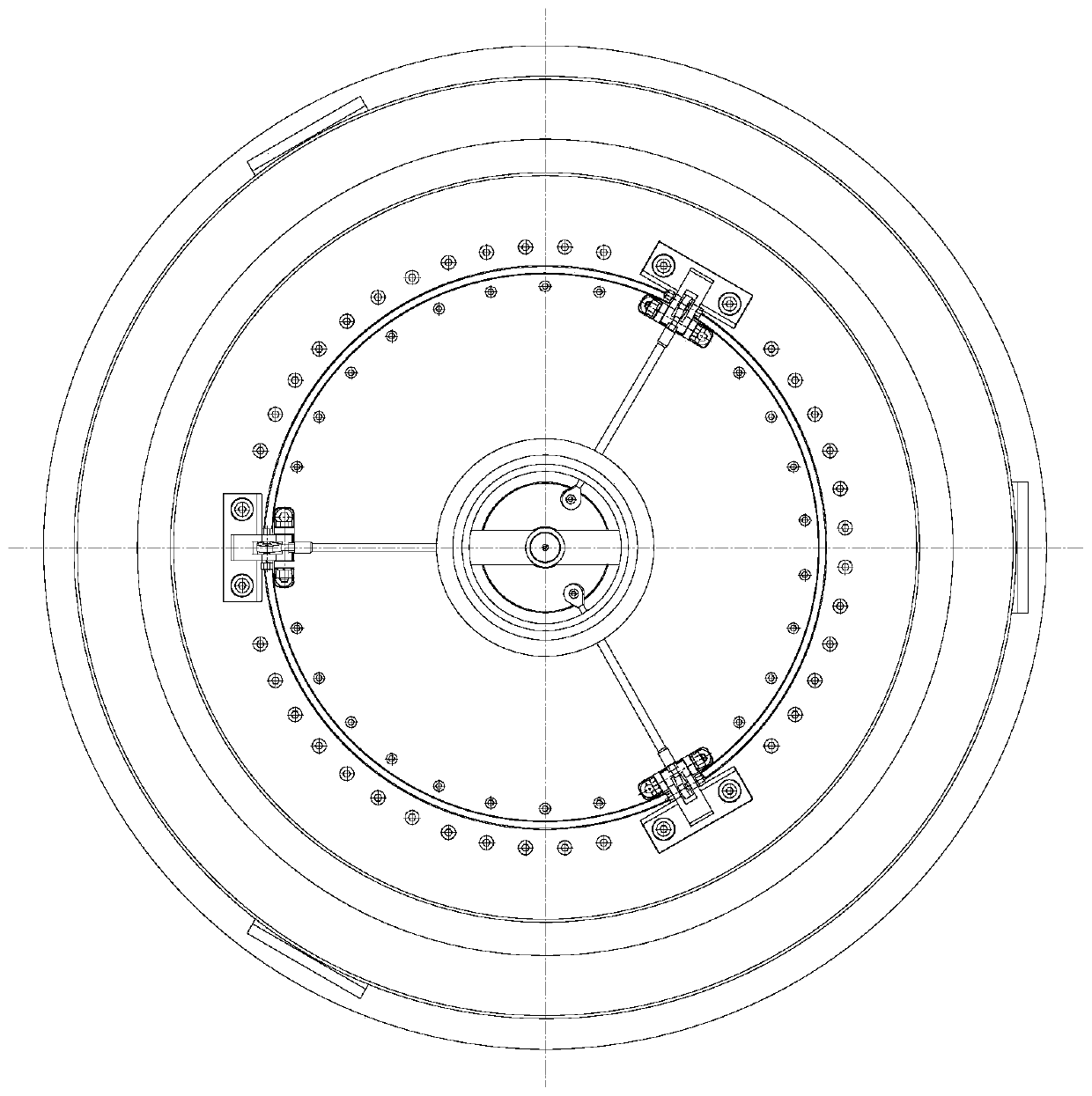

[0026] The invention comprises a hatch cover fence, a hatch cover, a torsion spring power-assisted connection mechanism, a rotating shaft passing through the hatch cover and a locking mechanism. The hatch cover is connected with the hatch cover fence through a torsion spring connection mechanism, and the hatch cover inner plate is installed through bolts, and a rotating shaft passing through the two is installed on the axis of the hatch cover and the hatch cover inner plate. Handwheel, turntable, limit disk, the rotation of the handwheel drives the rotating shaft to rotate, one end of the locking device is fixed on the turntable, and the other end is connected to the hatch cover, the rotating shaft drives the turntable to rotate, thereby driving the connecting rod assembly to move, and then driving the hook head Rotate around the hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com