Central slip-limiting differential device, driving system comprising same, and application

A differential device, central technology, applied in the direction of control device, transportation and packaging, vehicle components, etc., can solve the problems of increased fuel cost, increased vehicle cost, increased vehicle weight, etc., and achieves the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

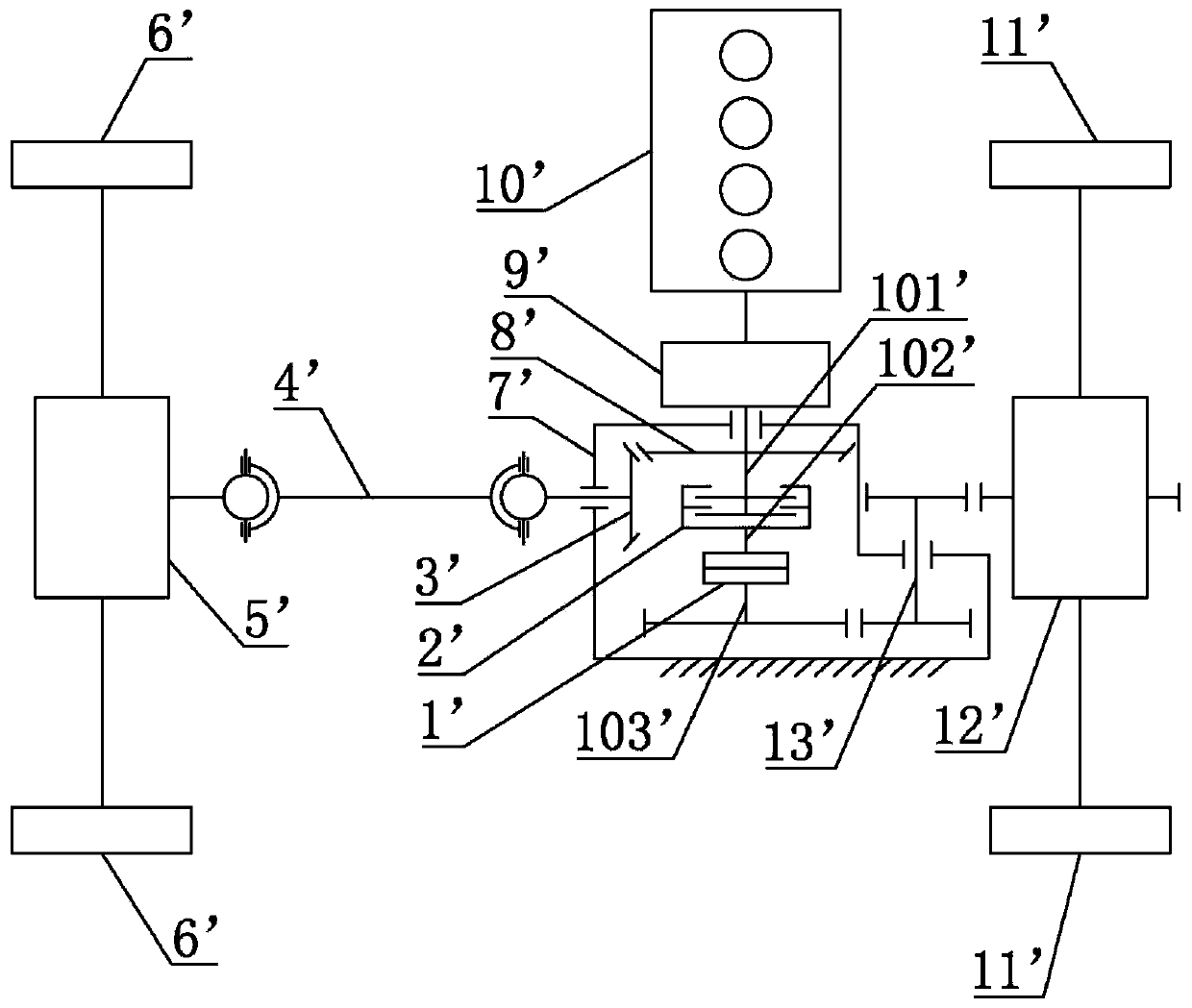

[0036] Such as figure 1 As shown, a central limited-slip differential device includes a power input shaft 101, a clutch 2, an intermediate transmission device 102, a ratchet assembly 1 and a power output shaft 103, wherein,

[0037] The clutch 2 includes a detachable and engaging active part and a driven part. The clutch 2 can be a multi-clutch plate type, or a jaw type, or a known other type of clutch 2. The combination of the clutch 2 The control mode of disconnection and disconnection can be controlled by the controller, and the active part is installed on the power input shaft 101, so as to be connected with the power mechanism and drive the active part to rotate; the power mechanism can be a power source (such as a motor, a drive Cylinder or engine 10 etc.) and the combined structure of transmission mechanism.

[0038]The ratchet assembly 1 includes parts A and B that cooperate with each other, and the driven part of the clutch 2 is connected with the part A of the ratch...

Embodiment 2

[0057] The central limited-slip differential device in Embodiment 2 is the same as Embodiment 1, which includes a power input shaft 101', a clutch 2', an intermediate transmission device 102', a ratchet assembly 1' and a power output shaft 103'. For specific structures, refer to Example 1.

[0058] But the drive system of its four-wheeled vehicle is slightly different from Embodiment 1, and its drive system comprises a kind of central limited-slip differential device described above, also comprises power mechanism, rear wheel drive shaft 4 ', rear axle differential 5 ', two rear wheels 6', front wheel drive shaft 13', front axle differential 12' and two front wheels 11', wherein,

[0059] The power mechanism includes an engine 10', a gearbox 9' and a central transfer case 7', the longitudinal direction of the engine 10' is consistent with the transverse direction of the four-wheeled vehicle, and the central transfer case 7' has driving bevel gears meshing with each other 8' a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com