Ceiling lamp with internal magnetic rotary screws

A ceiling lamp and screw technology, which is applied to the parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve the deformation of the cross groove and the flat groove, the screw cannot be rotated, and the screw cannot be screwed out from the object, etc. problem, to achieve the effect of being less susceptible to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

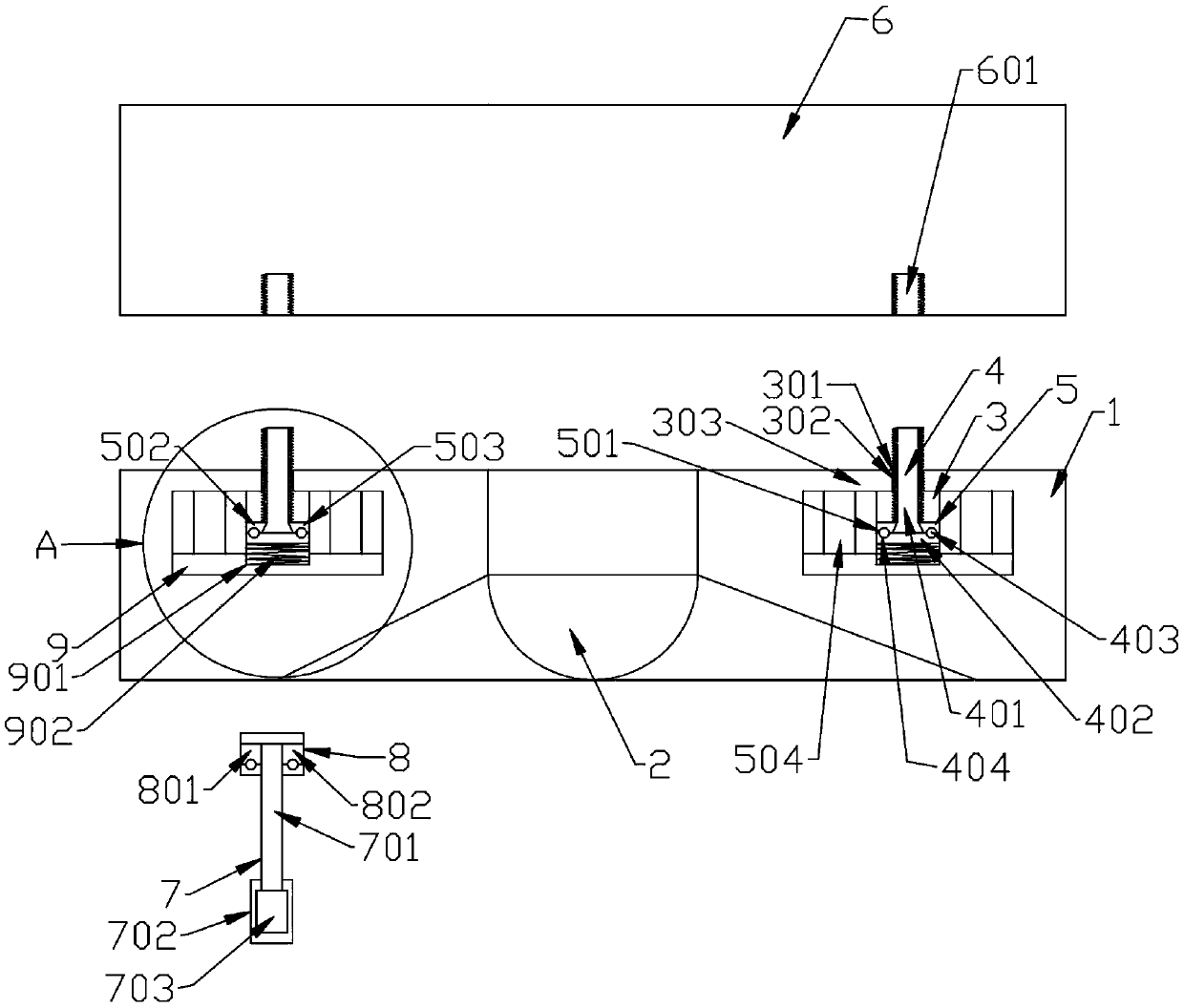

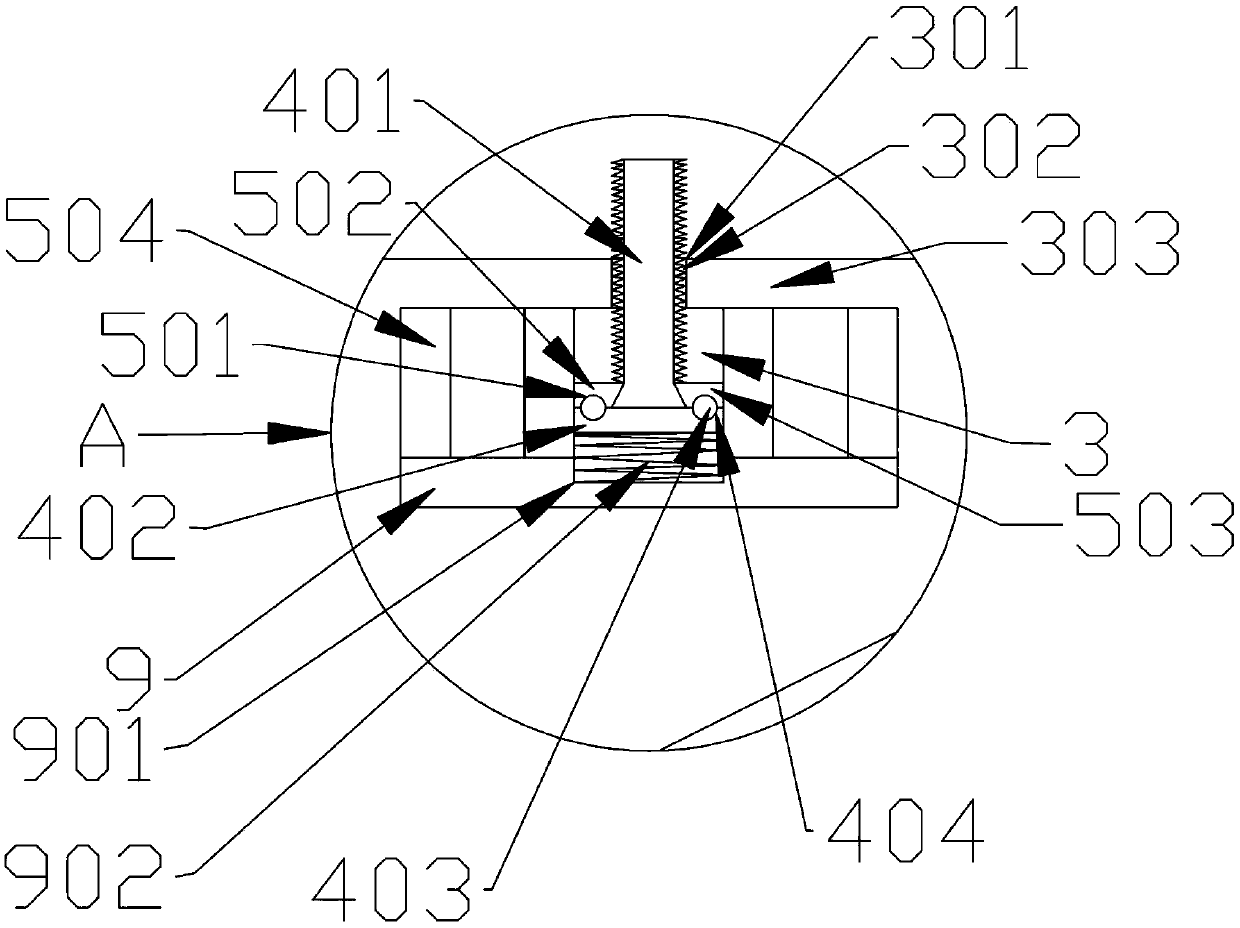

[0020] Example 1: see figure 2 , the applicant first drills a hole on the wall with an electric drill, and then places an expansion bolt in the hole, turns the screw protruding from the upper end of the ceiling lamp to place the hole with the expansion bolt, and the user only needs to hold the driver mechanism, so that the upper end surface of the driving mechanism and the lower end surface of the ceiling lamp are offset, and the two magnets with opposite magnetism attract each other, so at this time, the third magnetic block of the second magnetic mechanism will attract the first magnetic block of the first magnetic mechanism. The fourth magnetic block of the second magnetic mechanism can be attracted with the second magnetic block of the first magnetic mechanism; at this moment, the motor in the drive mechanism is turned on to make the motor run, and now the motor will drive the motor at the upper end of the connecting rod through the connecting rod. The second magnetic mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com