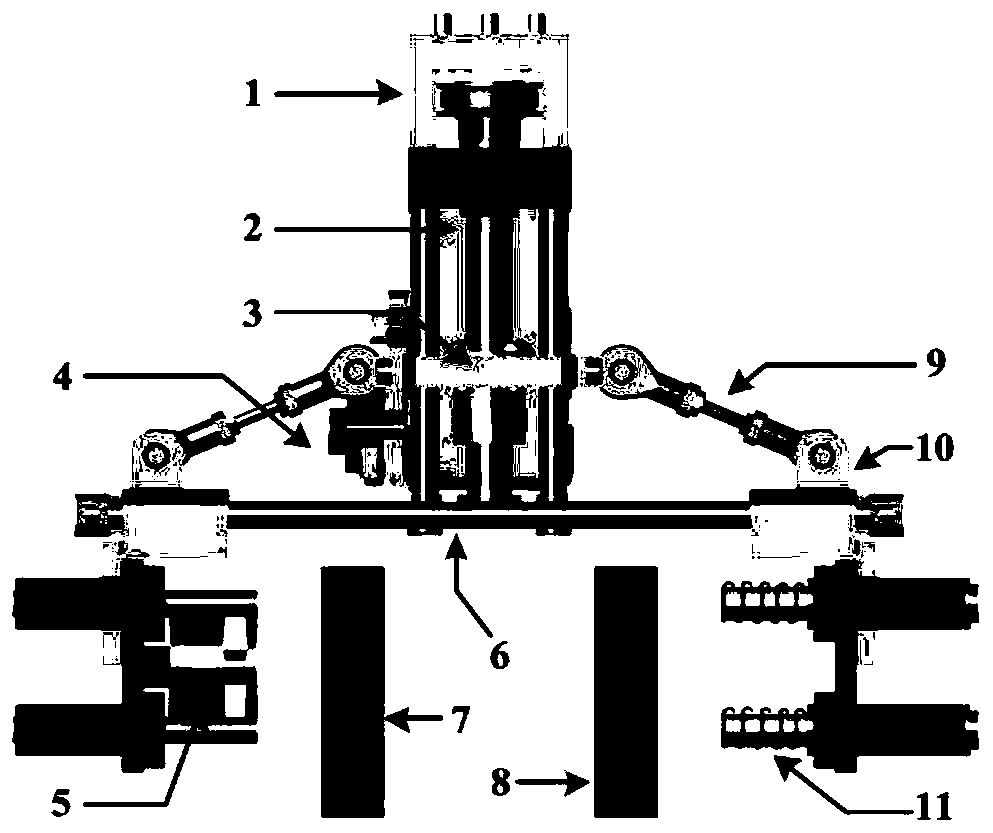

Parallel robot series type fruits clamping model-free self-adaptive smooth sliding mode impedance control method

A model-free self-adaptive, impedance control technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem of not considering the influence of the dynamic characteristics of the clamping mechanism on the control performance of fruit grasping, and avoid online real-time calculation. , Improve performance and achieve the effect of non-destructive clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

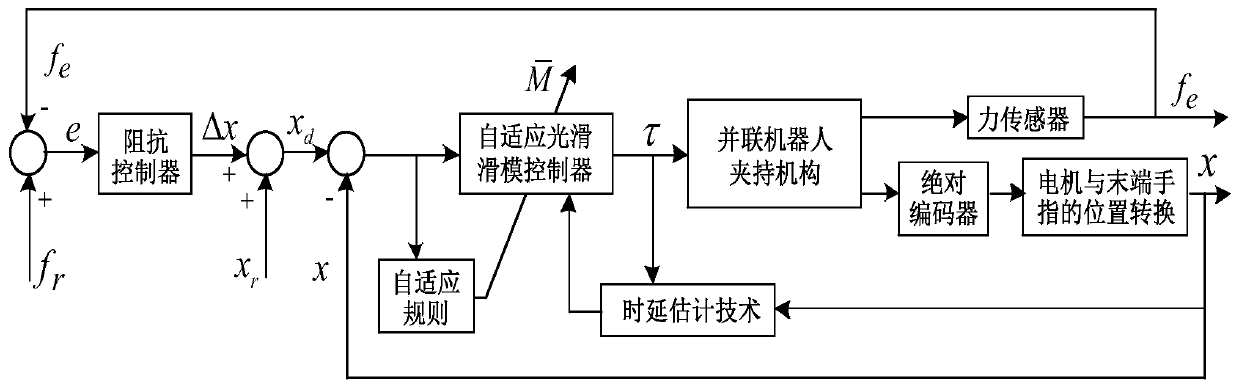

[0113] Aiming at the problem of non-destructive gripping of string fruits by parallel robots, the present invention proposes a model-free adaptive smooth sliding mode impedance control method, which does not need to establish a mathematical model of the parallel robot gripping mechanism, and has the ability to control mechanism movement and load changes Self-adaptive, it can well realize the non-destructive gripping of string fruits by parallel robots. The schematic diagram of model-free adaptive smooth sliding mode impedance control for parallel robot string fruit gripping is shown in Fig. figure 2 As shown, the specific implementation of the control method is as follows:

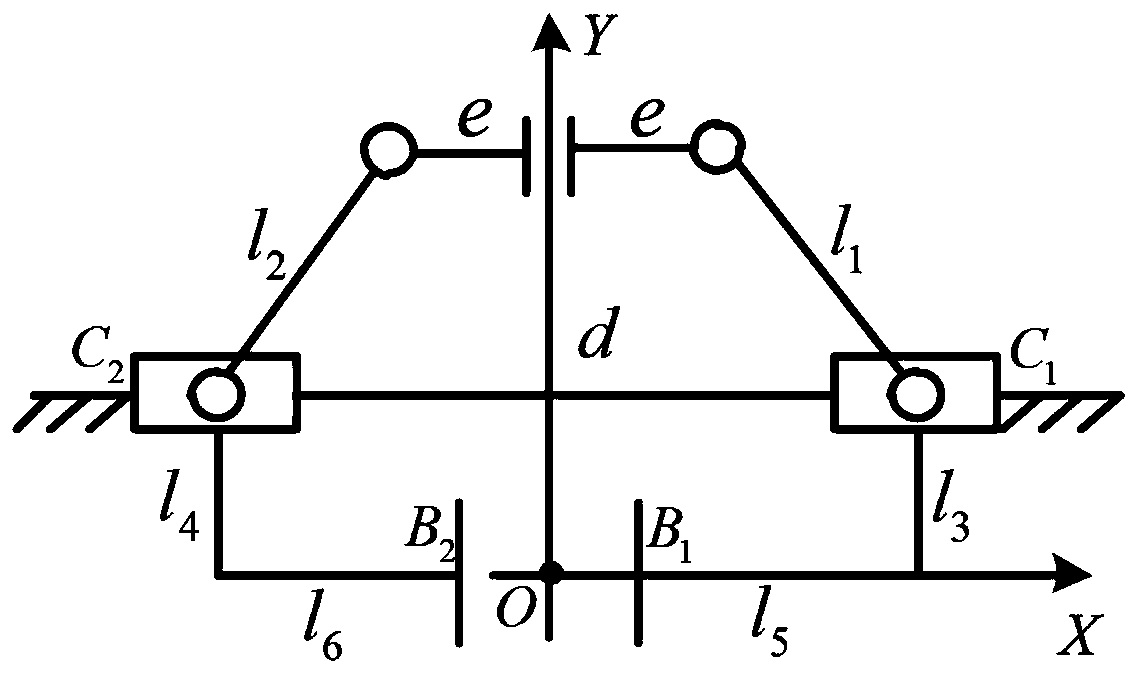

[0114] 1. Solve the relationship between the rotation angle of the active joint screw and the position conversion relationship of the clamping finger of the clamping mechanism

[0115] exist figure 2 In , the length constraint equation of the driven rod is used, and the kinematic equation of the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com