filter with filter lumen for aspiration

A filter and inner cavity technology is applied in the field of filters having a filter inner cavity for accommodating suction objects, and can solve the problems of reduced suction power of suction cleaning equipment, bacterial growth of filter bags, peculiar smell and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

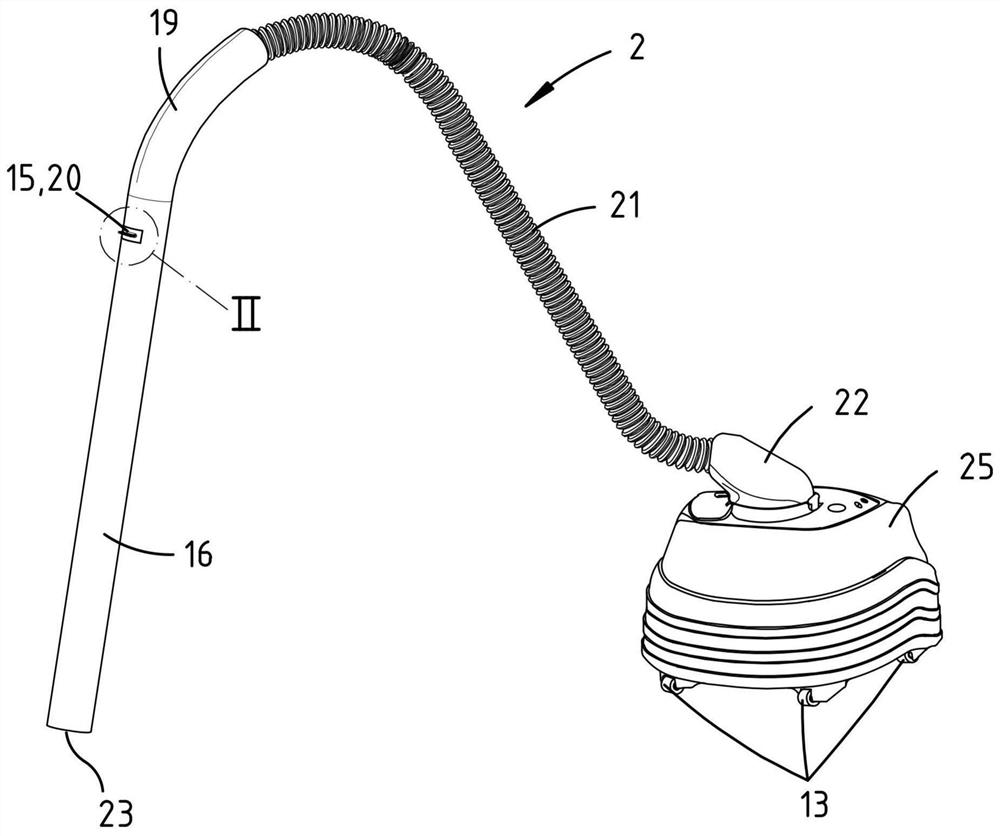

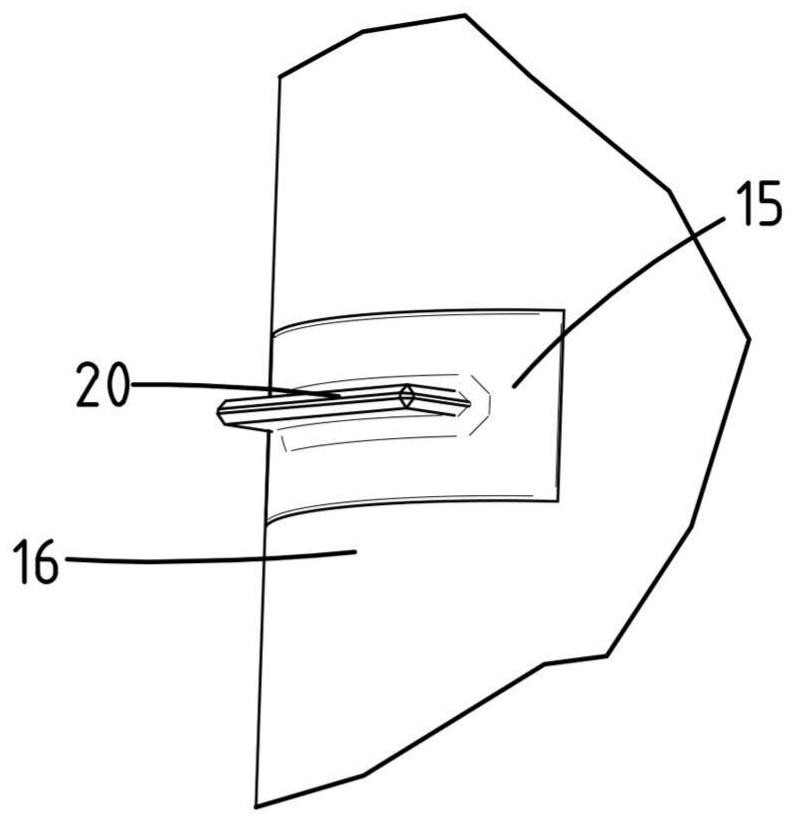

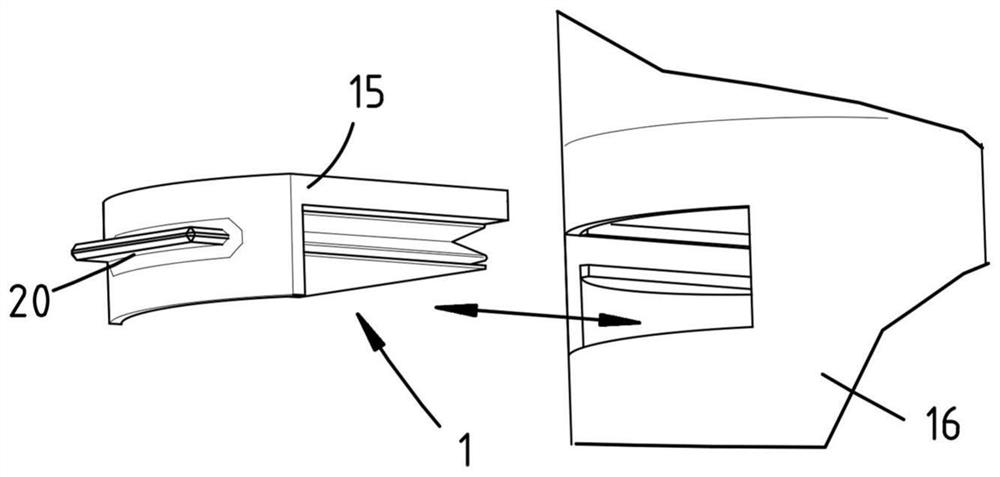

[0039] figure 1 The suction cleaning device 2 according to the invention is shown by way of example, which is designed here, for example, as a hand-held guided floor cleaner. The suction cleaning device 2 has a base device 25 and a hose 21 connected to the base device. The hose 21 and the base device 25 are articulated via a connecting region 22 . The hose 21 leads into the suction line 16 which has a suction opening 23 through which suction material can be sucked into the suction cleaning device 2 . For example, an additional device (not shown here) having cleaning elements for acting on the surface to be cleaned can also be arranged on the suction opening 23 . A partial area is provided on the suction pipe 16 as a handle 19 by means of which the user can guide the suction cleaning device 2 during suction operation. During the suction operation, the user typically pulls the base device 25 behind him, the user typically alternately pushes and pulls the suction tube 16 away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com