Method for judging degree of looseness of bolt based on vibration mode information

A vibration mode, bolt loosening technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of unfavorable detection and high detection requirements, and achieve low cost, improved discrimination accuracy, and strong real-time performance. Effect

Inactive Publication Date: 2019-07-23

XI AN JIAOTONG UNIV

View PDF5 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, methods such as acoustic emission signals, guided waves, and piezoelectric impedance are commonly used to detect the bolt connection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

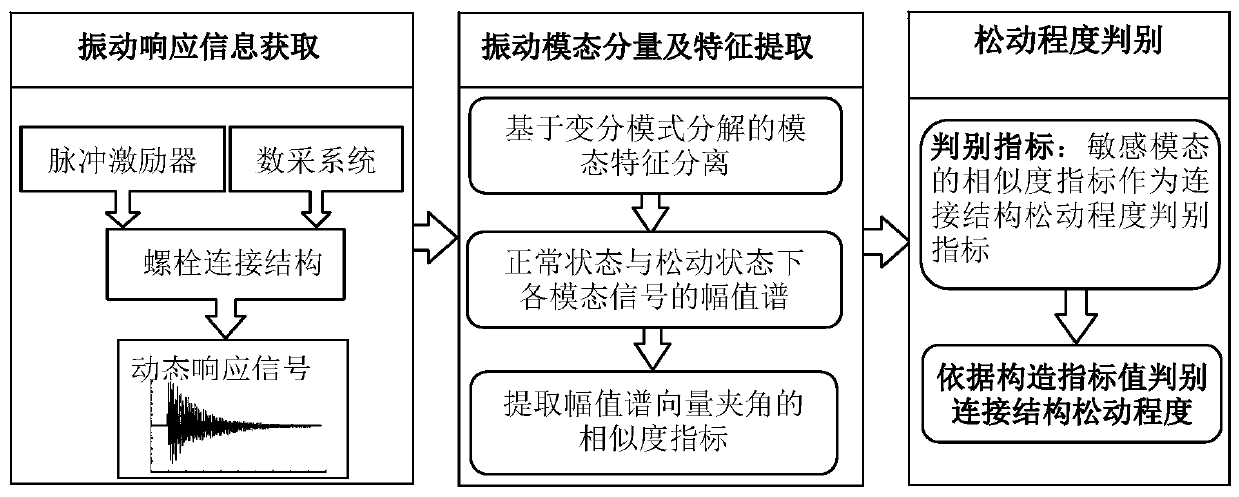

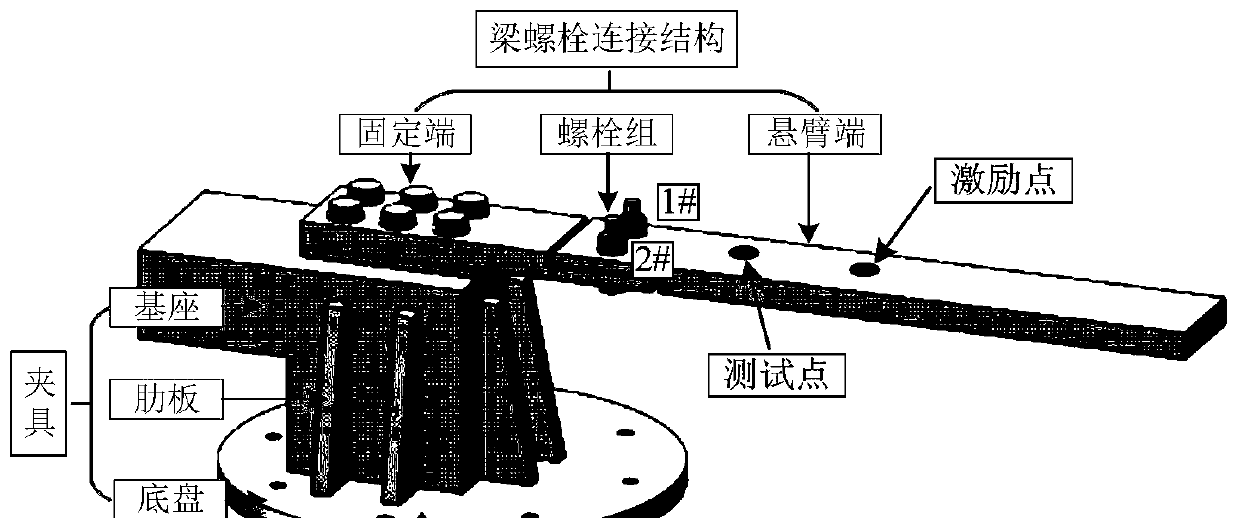

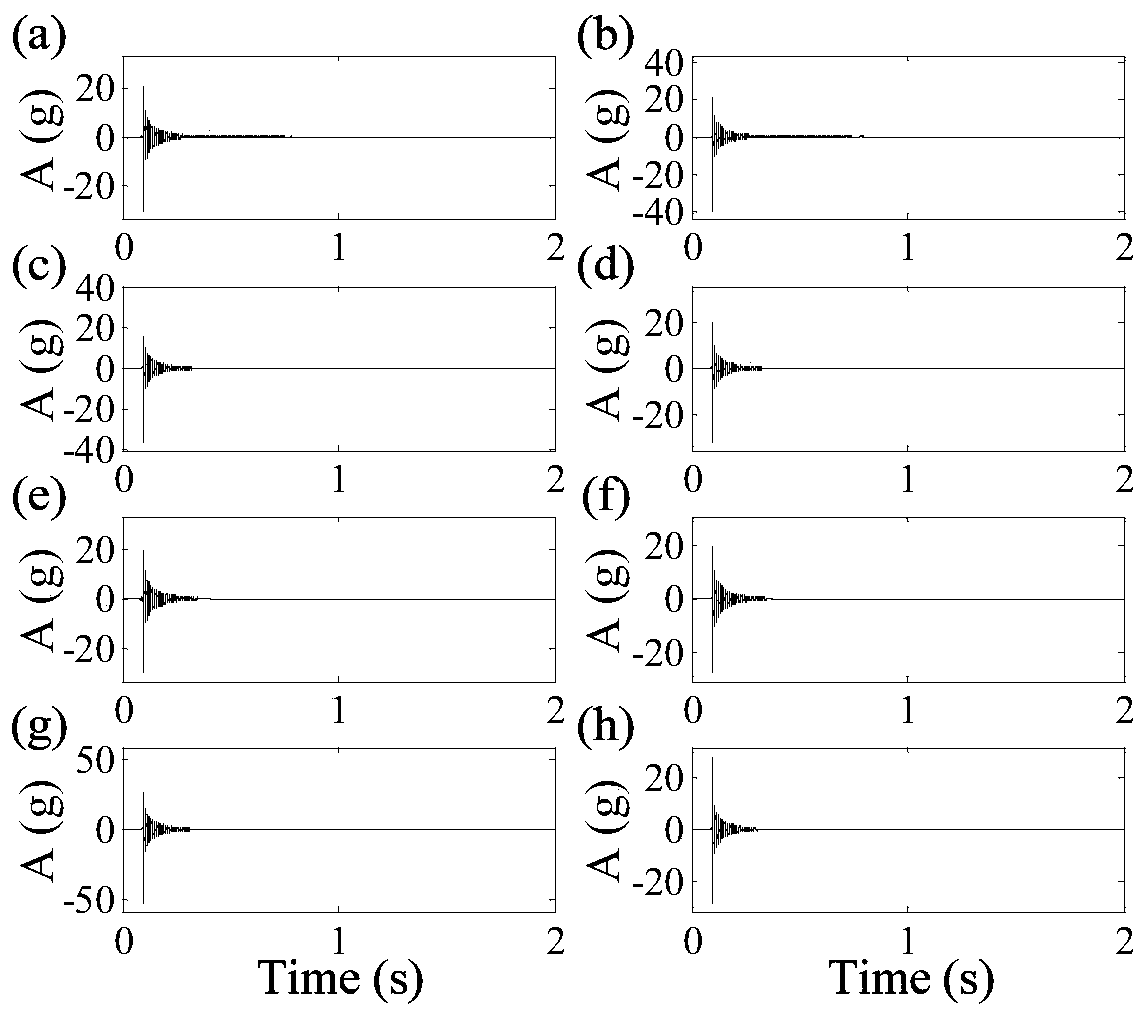

Login to View More Abstract

The invention discloses a method for judging degree of looseness of a bolt based on vibration mode information. The method comprises the following steps of firstly obtaining a freely attenuated vibration response signal by applying pulse excitation to the bolt connection structure; secondly realizing the multi-modal coupling feature separation on the vibration response signal based on a variational mode decomposition algorithm; thirdly calculating the frequency domain similarity index of each order of vibration mode component in two states; and finally judging the degree of looseness of the bolt connection structure according to the constructed index. The method is simple and practicable and is convenient for online non-destructive testing of the connection state of the bolt connection structure, is favorable for improving the judgment accuracy by judging the degree of looseness of the structure using the similarity index of the loose sensitive vibration mode component, and is beneficial to describe the change of vibration mode information caused by structural state changes and reflect the health status of the structure by constructing the detection index including frequency and amplitude information of the signal from the frequency domain, thereby having important engineering practical value.

Description

technical field [0001] The invention relates to a method for detecting the health state of a mechanical structure, in particular to a method for discriminating the degree of bolt looseness based on vibration mode information. Background technique [0002] Bolt connection is widely used because of its simple structure, easy assembly and disassembly, and reliable connection. When the bolt connection state becomes poor, the vibration increases under the external alternating load, which may cause the bolts to slip, separate or even loosen, and even lead to product failure and catastrophic accidents. Loosening, as one of the main failure modes of bolted connections, refers to the relative circumferential displacement of bolts and nuts as the use time increases, and the clamping force of bolts decreases. The failure sign is that the clamping force drops to a certain level and loses working ability. Therefore, effectively detecting the looseness of connecting structure bolts in a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M7/06

CPCG01M7/025G01M7/06

Inventor 张周锁郭燕飞曹建斌杨文展邓文敬

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com