Fuel gas direct-buried pipeline leakage point positioning method based on two-point optimizing tracing

A leakage point and pipeline technology, which is applied in the field of locating the leakage point of directly buried gas pipelines, can solve the problems of large manpower and material resources and economic losses, and achieve the effect of improving accuracy and reducing the number of soil drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

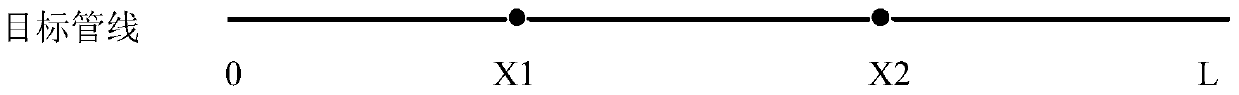

[0032] Specific implementation mode 1: In this implementation mode, the specific process of locating the leakage point of the directly buried gas pipeline based on two-point optimization and traceability is as follows:

[0033] The invention adopts a new method combining interval qualitative and accurate positioning to realize the leakage positioning of directly buried gas pipelines.

[0034] First, calculate the maximum diffusion velocity of natural gas in different soils (sandy soil, loam, clay) according to the soil physical parameters, calculate and determine the maximum leakage radius of natural gas, and then based on the natural gas concentration monitored at any position in the soil, or any inspection well or The natural gas concentration is monitored in the inspection well, and then the two endpoints of the direct buried pipeline from the monitoring point to the possible leakage point of the natural gas pipeline are determined. This completes the first step, locating th...

specific Embodiment approach 2

[0042] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the maximum diffusion radius R in the step 1 is selected based on the following formula:

[0043] R=vt

[0044] Among them, t is the diffusion time from the leakage source to the monitoring point (estimated value, calculated as 24 hours a day and night); v is the diffusion speed of the leaked natural gas in the soil.

[0045] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in the step two, the target pipelines that may leak may be obtained in the step one are screened to determine the leaking pipeline; the specific process is:

[0047] First, prioritize the target pipelines that may leak in the circle, based on the distance from the alarm inspection well or alarm monitoring point, and sort the distance from small to large, and the order is: i, i+1,..., I ; The target pipeline with a small distance from the monitoring point is given priority to drilling and excavation; the closer to the monitoring point, the target pipeline that may leak is more likely to leak, and the priority is to carry out drilling and excavation;

[0048] First, drill a hole on the ground above the target pipeline i, and use a portable natural gas concentration sensor to monitor the natural gas concentration at the drill hole;

[0049] If the concentration of nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com