A gear shaft structure

A technology of gear shafts and gears, which is applied in the direction of belts/chains/gears, shafts, couplings, etc., and can solve problems such as the inability to fix the gear shaft center and easy deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

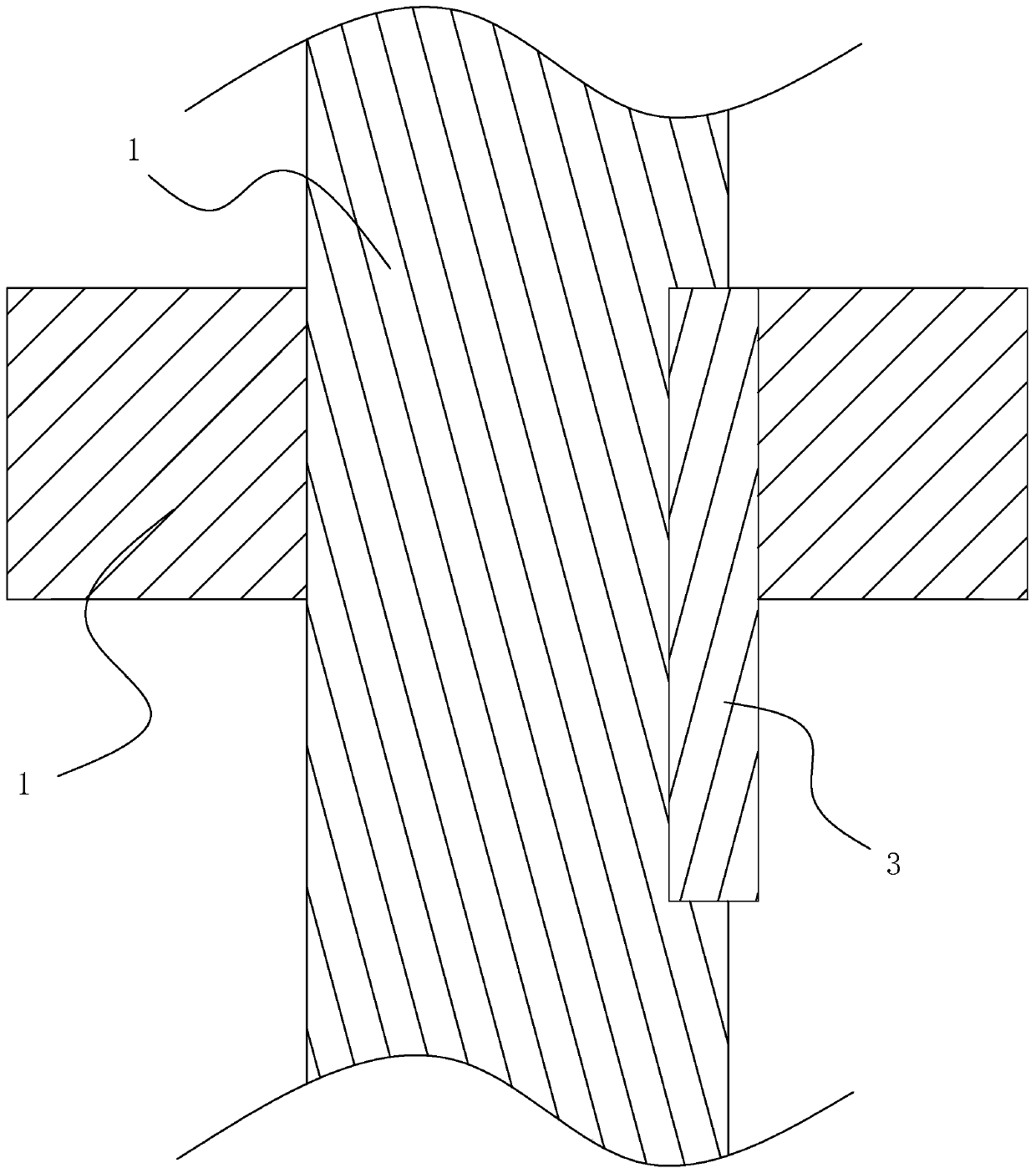

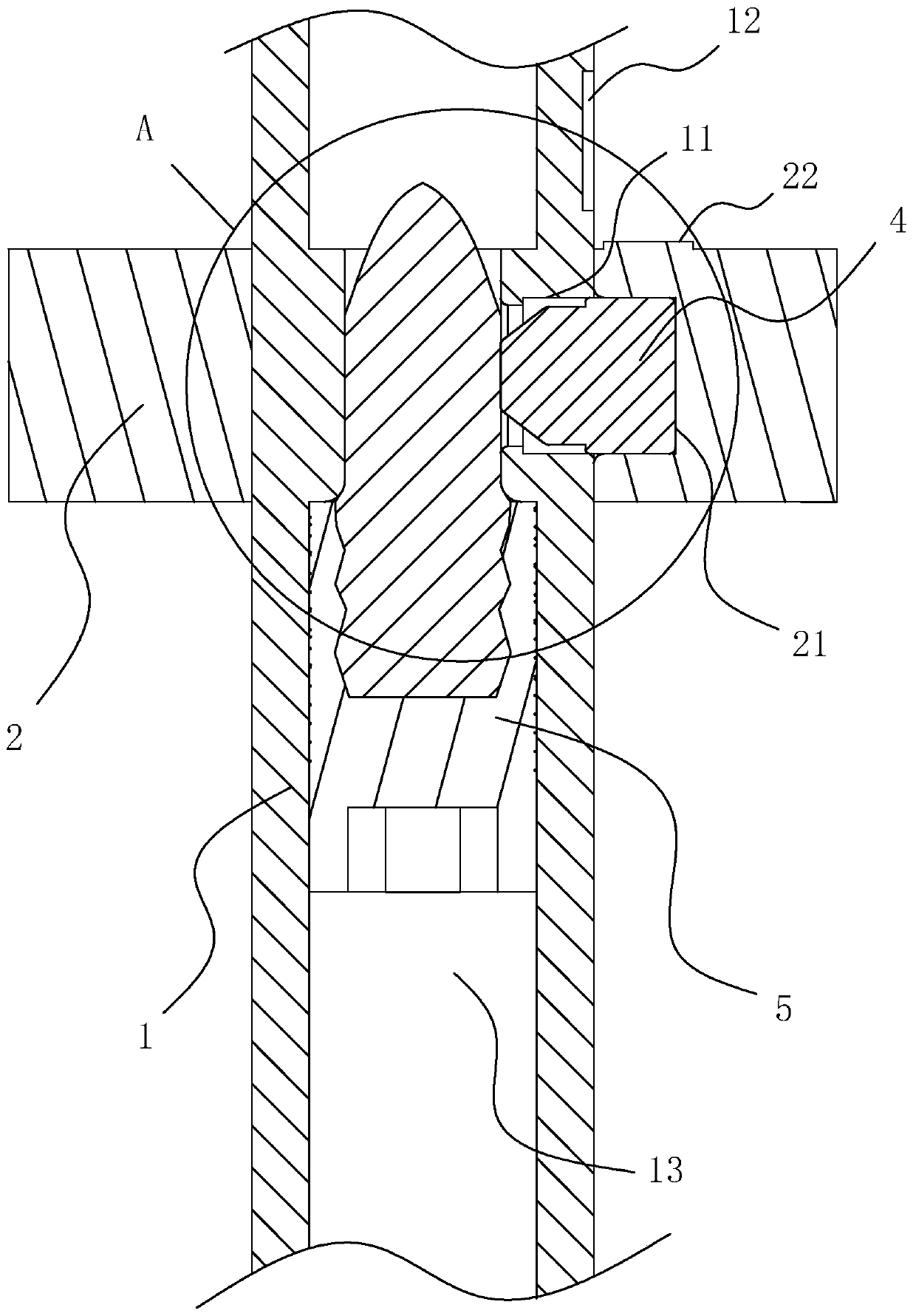

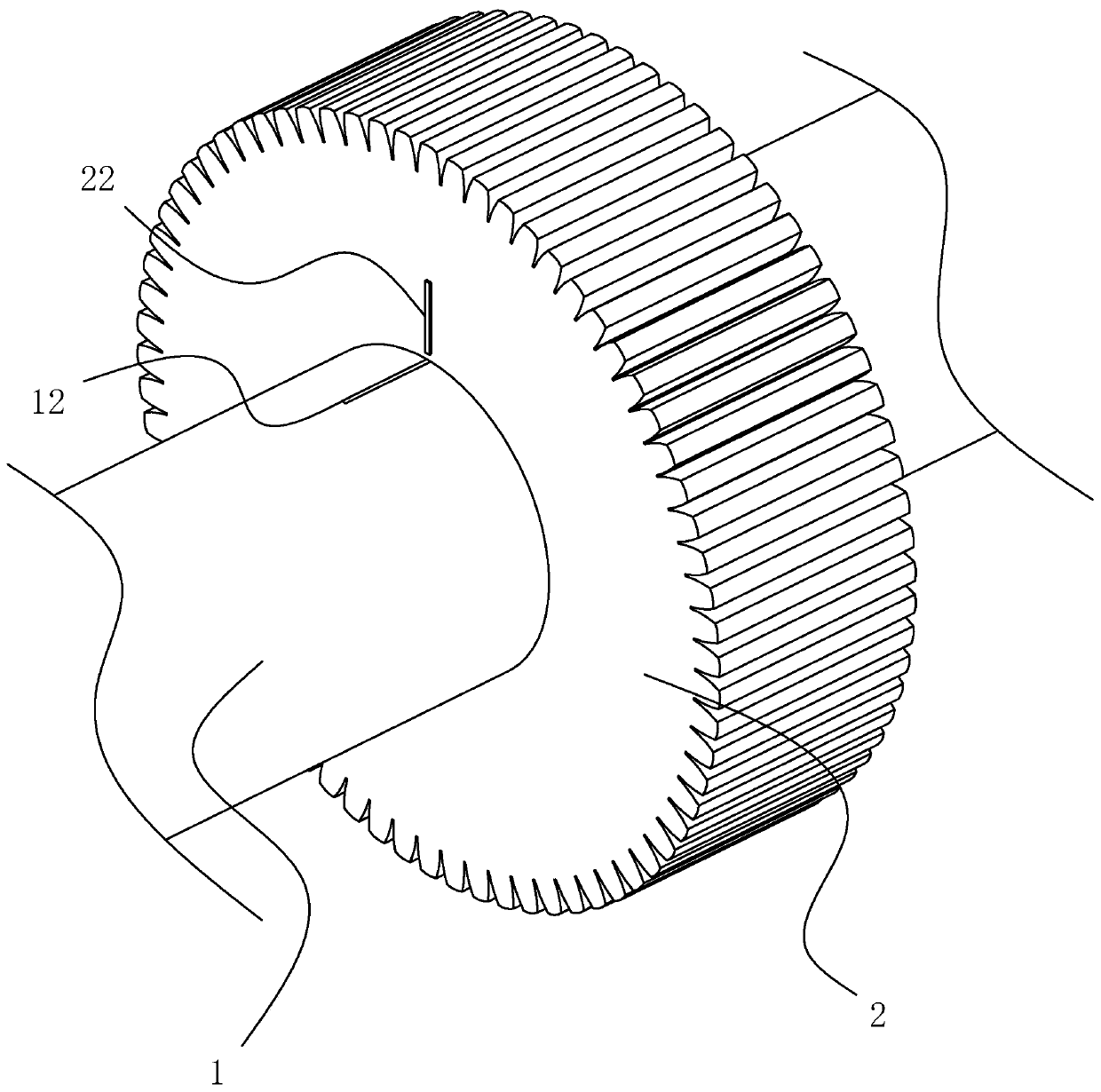

[0037] A gear shaft structure such as figure 2 As shown, it includes a metal round rod shaft 1, a gear 2 sleeved on the metal round rod shaft 1 for the transmission function, set on the metal round rod shaft 1 and capable of clamping with the gear 2 for torque transmission The clamping block 4 and the pressing rod 5 inserted into the metal round rod shaft 1 for pushing the clamping block 4 and the gear 2 to engage; wherein, a metal round rod shaft 1 is provided with a 1 The coaxial line is set for inserting the compression rod 5 into the inner cavity 13 of the metal round rod shaft 1. On the metal round rod shaft 1, there is a pair of two ends connected with the inner cavity 13 and the metal round rod shaft 1 respectively. The outer wall of the gear 2 is communicated with the notch 11 corresponding to the installation position of the gear 2 for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com