Cylinder block structure of hybrid opposed-piston and mixed-layer rotor-stator engine

A technology of opposing pistons and engines, applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of high center of gravity of the engine, large engine volume, too long cylinder, etc., and achieve the solution of installation position and installation space. Conflict, easy maintenance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

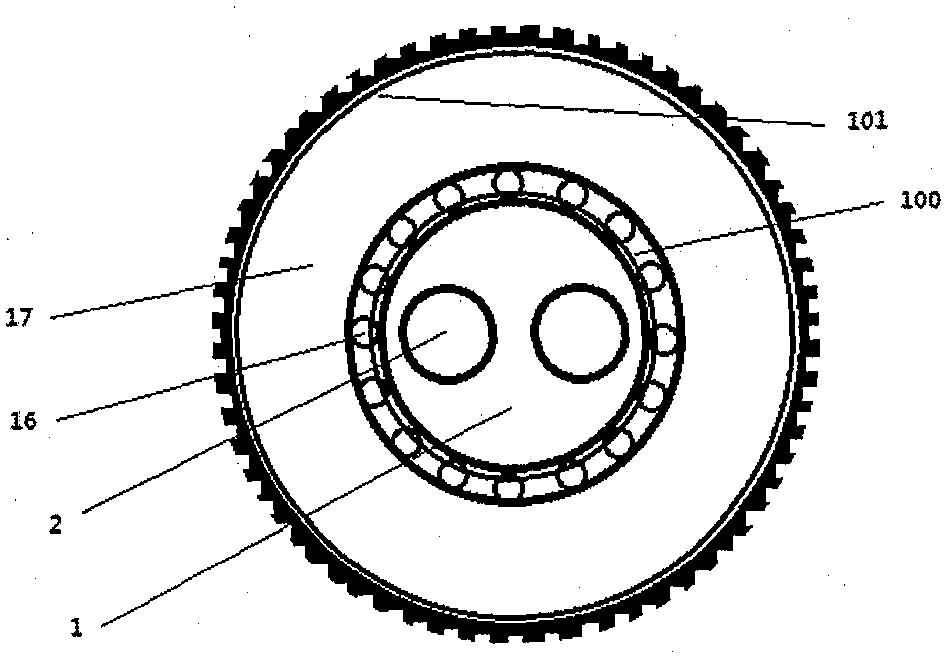

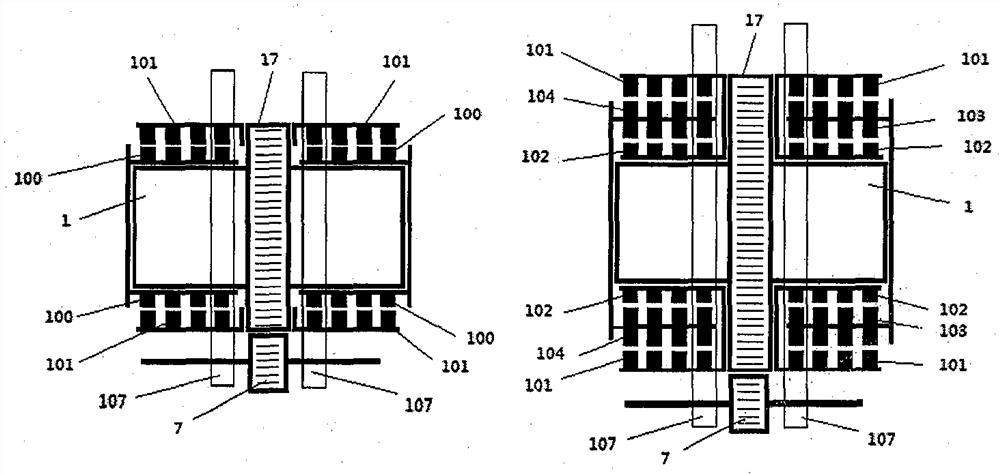

[0071] exist figure 1 Among them, the triangular integral casting cylinder body is integrally cast by the opposed piston cylinder (4), three square columns (3) and a round shaft with two large round holes, and the opposed piston (59) in the cylinder is connected to the connecting rod (10) The gear (7) driving the mixed-flushing and mixed-stroke main transmission shaft (5), the gear (9) of the sub-shaft crankshaft (8) and the flywheel gear (17) of the non-rotating round shaft (1) of the central shaft are meshed In operation, the electromagnetic stator (100) sleeved on the non-rotating round shaft (1) of the central shaft drives each other with the permanent magnet rotors (101) installed on both sides of the bearing (16), and the non-rotating round shaft (1) of the central shaft The axial center horizontal large circular hole (2) is screwed together with the large circular hole on the top surface of the engine fixing bracket arc arched panel (12) and the large circular hole in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com