Fireproof wooden door with mortise and tenon structures

A mortise and tenon, wooden door technology, applied in the field of fireproof wooden doors, can solve the problems of slow assembly speed, unfavorable inventory, etc., and achieve the effect of improving fireproof performance, stable structure, preventing fire penetration and poisonous smoke intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

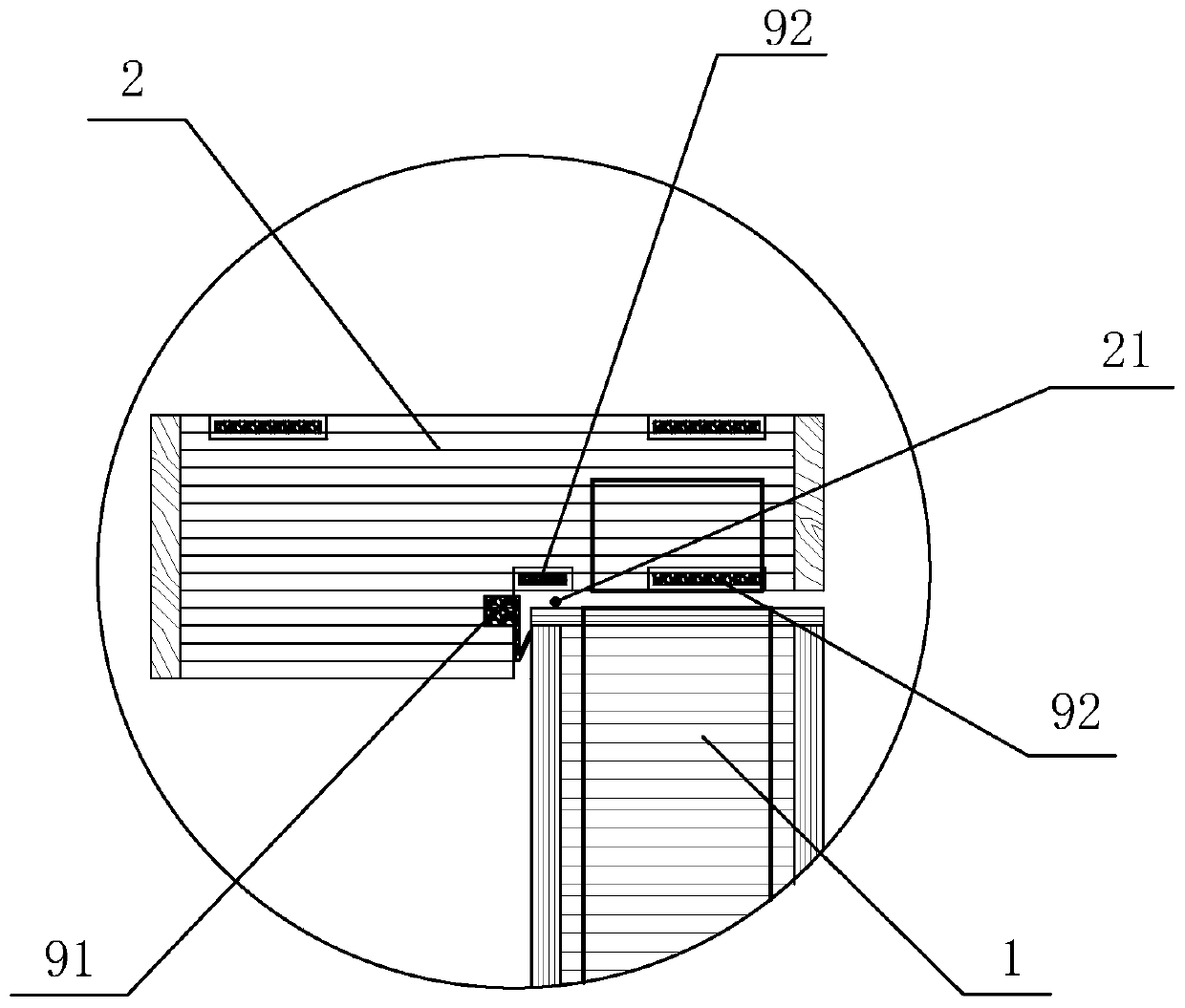

[0037] See attached Figure 1-7 , a fireproof wooden door with mortise and tenon structure, including a door leaf 1 and a door frame 2 made of fireproof boards. The riser 4 is arranged on the upper edge and the lower edge of the door leaf and is connected with the transverse edge of the door core plate 3, and the edge 5 is connected with the longitudinal edge of the door core plate 3; the door core plate 3 includes several pieces, and adjacent The lateral sides between the door core boards 3 are connected by a lock header 6 . Specifically, the core panel 3 includes a first core panel 31 and a second core panel 32 from top to bottom, the upper edge of the first core panel 31 and the lower edge of the second core panel 32 pass through a The connecting plate 7 is connected with the riser 4; the lower edge of the first door core board 31 and the upper edge of the second door core board 32 are connected through the lock riser 6; the left and right sides of the first door core boar...

Embodiment 2

[0047] See attached Figure 6-11 The difference between this embodiment and the above-mentioned embodiment is that the fireproof wooden door of the mortise and tenon structure is a double door, the door leaf 1 includes two leaves, and the door leaf 1 is provided with a fireproof door 11 at the contact opening 11 when the door leaf 1 is closed. sealing strip.

[0048] The fireproof sealing strip includes a first fireproof sealing strip 91 , a second fireproof sealing strip 92 and a third fireproof sealing strip 93 .

[0049] The first fireproof sealing strip 91 is made of elastic fireproof material obtained by compounding expanded graphite and flexible resin, and it includes a strip-shaped main body 911. One side of the main body 911 extends horizontally with a wide side 912. The wide side The side of the side 912 far away from the main body 911 is obliquely bent with an elastic hem 913 . The included angle is an acute angle q, preferably 45°, and the main body 911 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com