Alga graded filtering device for removing algae in coupling manner

A technology of graded filtration and algae, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems that algae cannot be discharged through graded filtration, and algae clogging cannot be prevented, so as to achieve the effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

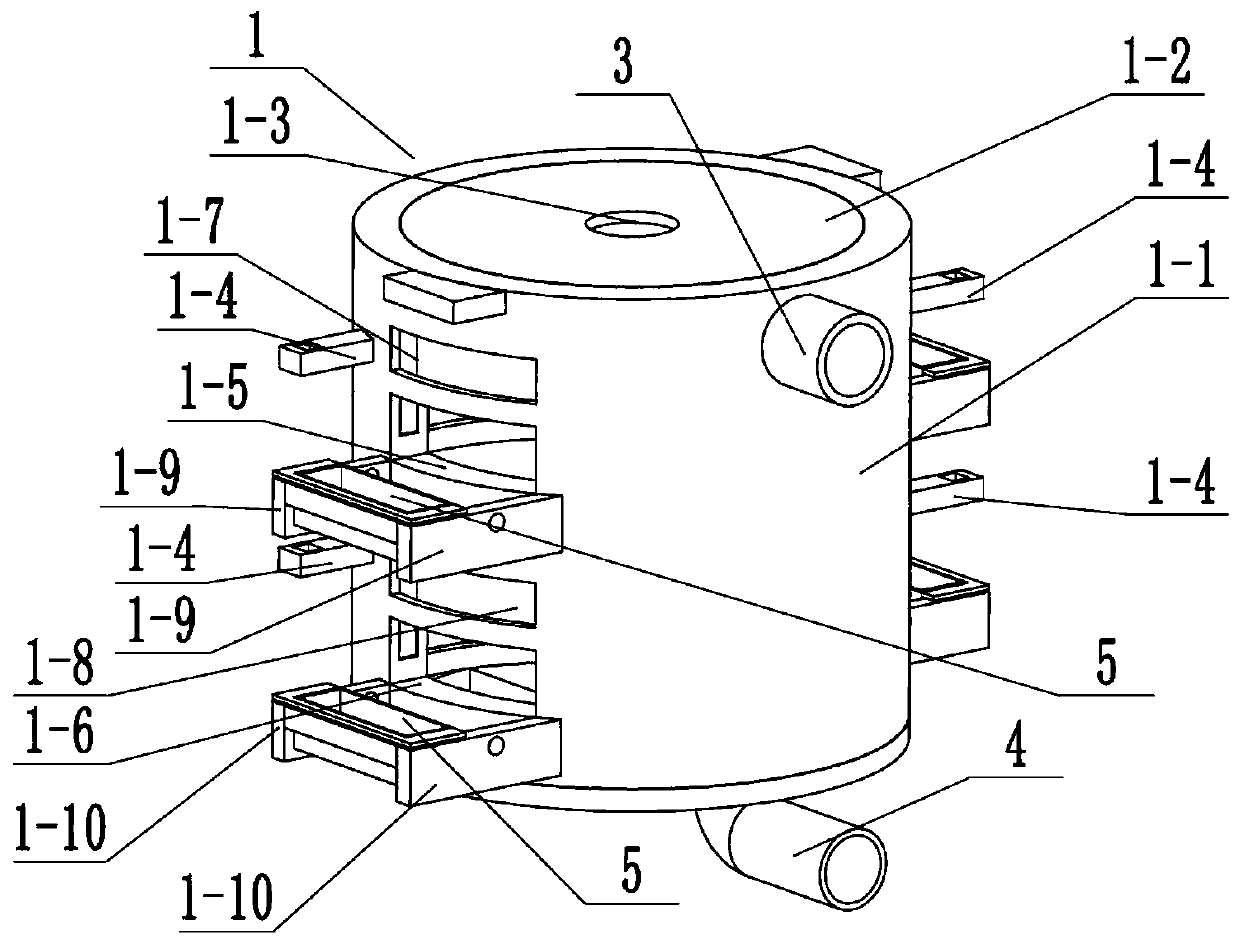

[0031] Such as Figure 1 to Figure 11 As shown, an algae grading filter device for coupling algae removal includes an algae sub-filter tank 1, a collection driver 2, a feed pipe 3, a liquid recovery pipe 4, four algae recovery frames 5, and two algae recovery pushers 6. The collection driver 2 is rotatably connected to the upper end of the algae sub-filter 1, the feed pipe 3 and the liquid recovery pipe 4 are respectively fixedly connected and communicated with the upper and lower ends of the algae sub-filter 1, and the left and right sides of the collection driver 2 The four algae recovery frames 5 are respectively arranged on the outer wall of the algae sub-filter 1, and the two algae recovery propellers 6 are connected to the side of the algae sub-filter 1 respectively. Left and right ends. A batch of algae-containing liquid is added to the algae sub-filter 1 through the feed pipe 3, and the collection driver 2 is connected to the power, and the algae in the algae sub-filt...

specific Embodiment approach 2

[0033] Such as Figure 1 to Figure 11 As shown, this embodiment will further explain Embodiment 1. The algae filter tank 1 includes a tank body 1-1, an upper end cover 1-2, a central rotating hole 1-3, and four rack sliding positioning rods 1 -4. Two upper discharge outlets 1-5, two lower discharge outlets 1-6, two upper valve chutes 1-7, two lower valve chutes 1-8, four upper fixed connecting rods 1 -9 and four lower fixed connecting rods 1-10, the upper end of the tank body 1-1 is fixedly connected to the upper end cover 1-2, and the central rotating hole 1-3 is arranged at the center of the upper end cover 1-2, and the tank body The left and right ends of 1-1 are respectively fixedly connected with two rack sliding positioning rods 1-4, the two upper discharge outlets 1-5 are respectively arranged on the upper sides of the left and right ends of the tank body 1-1, and the two lower discharge outlets 1-6 are respectively arranged on the lower side of the left and right ends...

specific Embodiment approach 3

[0035] Such as Figure 1 to Figure 11 As shown, this embodiment will further illustrate Embodiment 2. The algae separation filter tank 1 also includes an upper separation filter plate 1-11, a plurality of coarse separation circular holes 1-12, and two upper recovery push grooves 1-11. 13. The lower sub-filter plate 1-14, multiple fine-separation round holes 1-15 and two lower recovery push grooves 1-16, the upper sub-filter plate 1-11 and the lower sub-filter plate 1-14 are fixed from top to bottom Connected to the inner wall of the tank body 1-1, multiple coarse round holes 1-12 are arranged vertically through the upper filter plate 1-11, and multiple fine round holes 1-15 are arranged vertically through the lower filter plate 1 On -14, two upper recovery push grooves 1-13 are respectively arranged up and down on the left and right ends of the upper sub-filter plate 1-11, and two lower recovery push grooves 1-16 are respectively arranged up and down on the lower sub-filter pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com