Automated analysis device and automated analysis method

A technology of automatic analysis device and control device, which is applied in the direction of analyzing materials, analyzing materials by chemical reaction, and analyzing materials by observing the influence on chemical indicators, which can solve problems such as easy accumulation of fouling, and achieve inhibition analysis. Decrease in accuracy or effect of ensuring cleaning performance and improving analysis accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

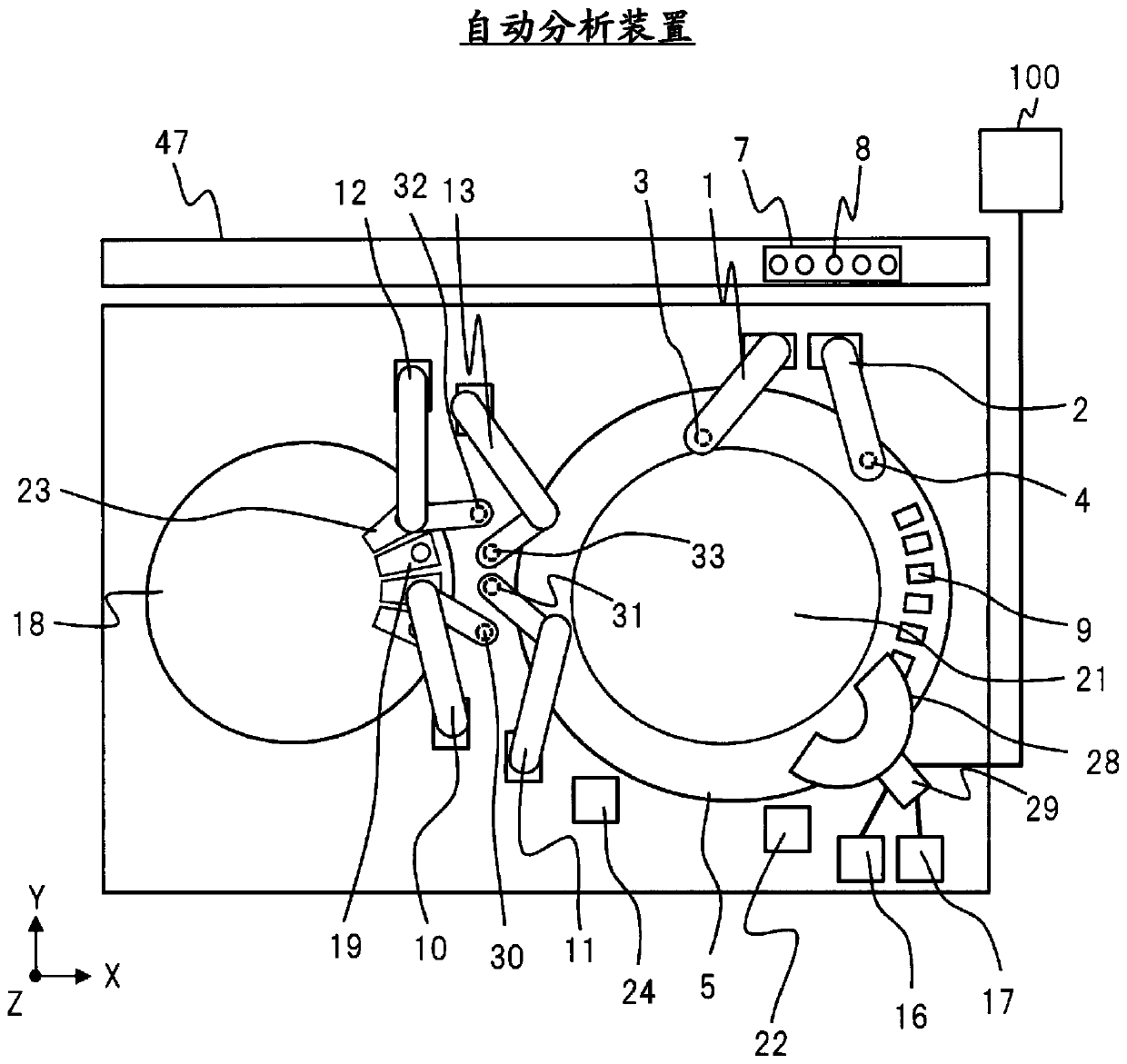

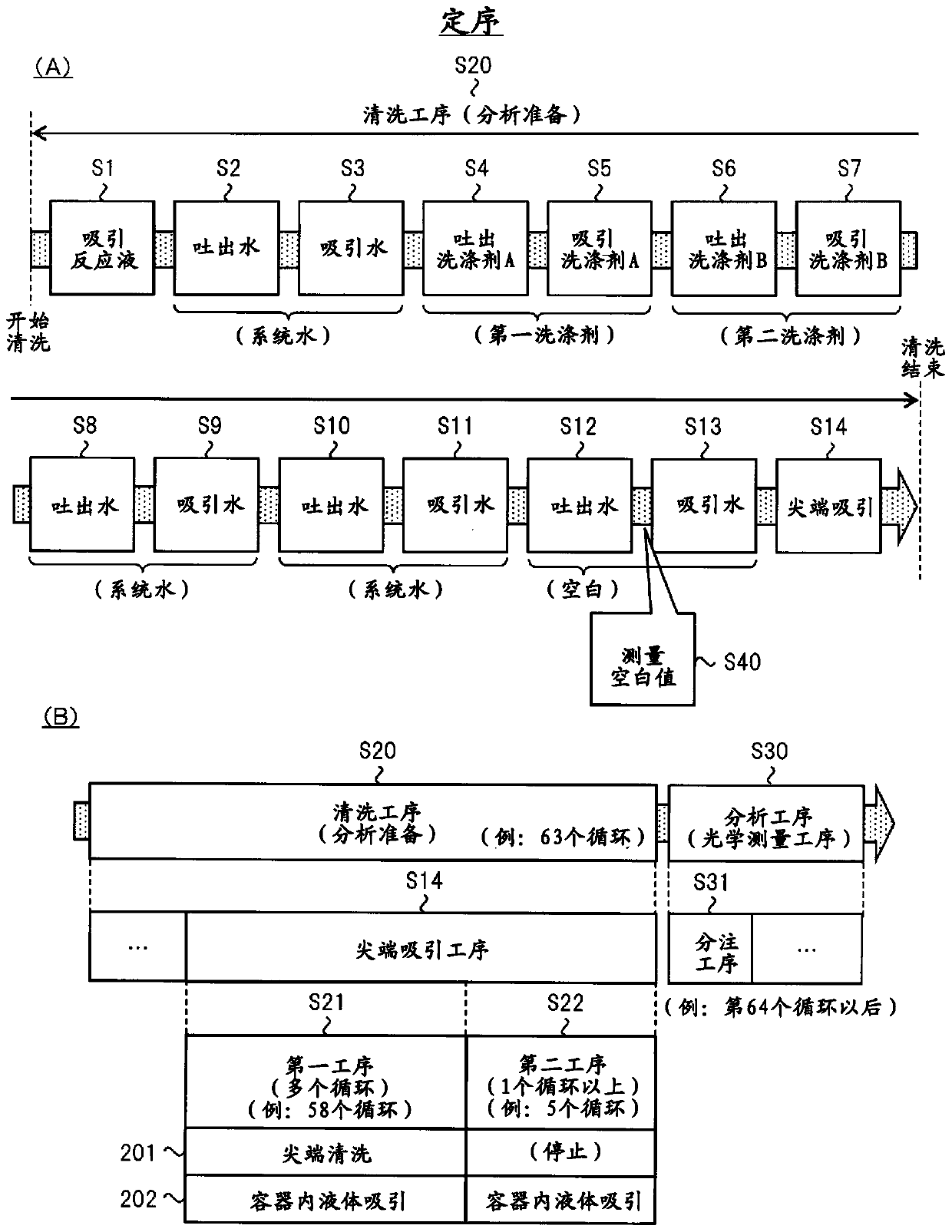

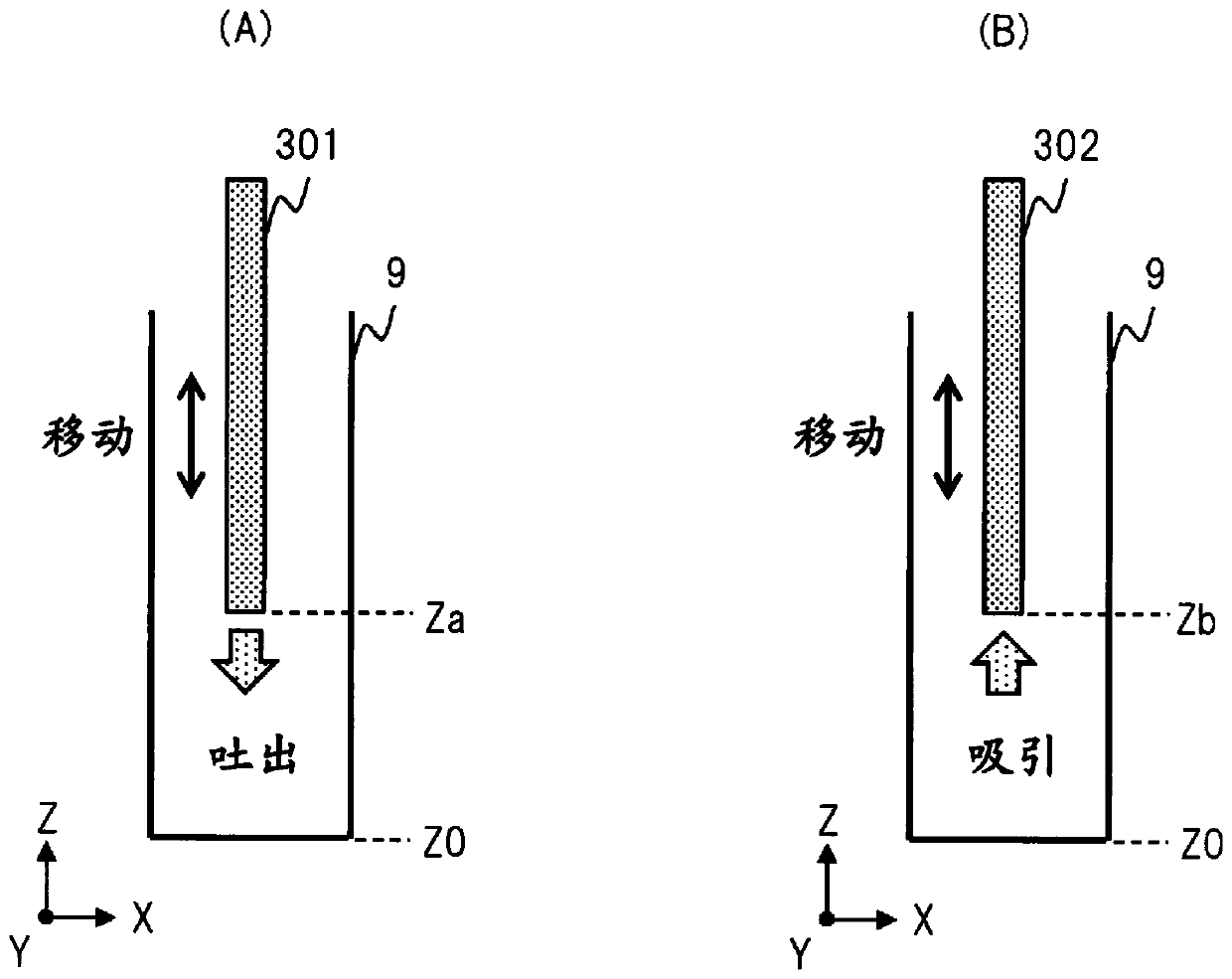

[0036] use Figure 1 to Figure 14 , the automatic analyzer according to Embodiment 1 of the present invention will be described. The automatic analyzer of Embodiment 1 has a unique cleaning function. The automatic analysis method of Embodiment 1 is a method having steps performed by the automatic analysis device of Embodiment 1.

[0037] [Automatic analyzer (1)]

[0038] figure 1 The structure of the automatic analyzer of Embodiment 1 is shown. The automatic analyzer includes a control device 100, a reaction disk 5, a reaction container 9, a reagent disk 18, a reagent bottle 23, a rack 7, a sample container 8, sample dispensing mechanisms 1, 2, sample dispensing nozzles 3, 4, Sample transfer mechanism 47, reagent dispensing mechanisms 10-13, reagent dispensing nozzles 30-33, spectrophotometer 22, stirring mechanism 24, reaction container cleaning mechanism 29, liquid delivery pump 16, vacuum suction pump 17, etc.

[0039] Except for the part of the control device 100 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com