Universal sodium-cooled fast reactor assembly single-body hydraulic experiment bench and experiment method thereof

A technology for sodium-cooled fast reactors and hydraulic experiments, which is used in reactors, nuclear reactor monitoring, and greenhouse gas reduction. It can solve problems such as poor scalability, less flow characteristics of all components, and lack of experimental research. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

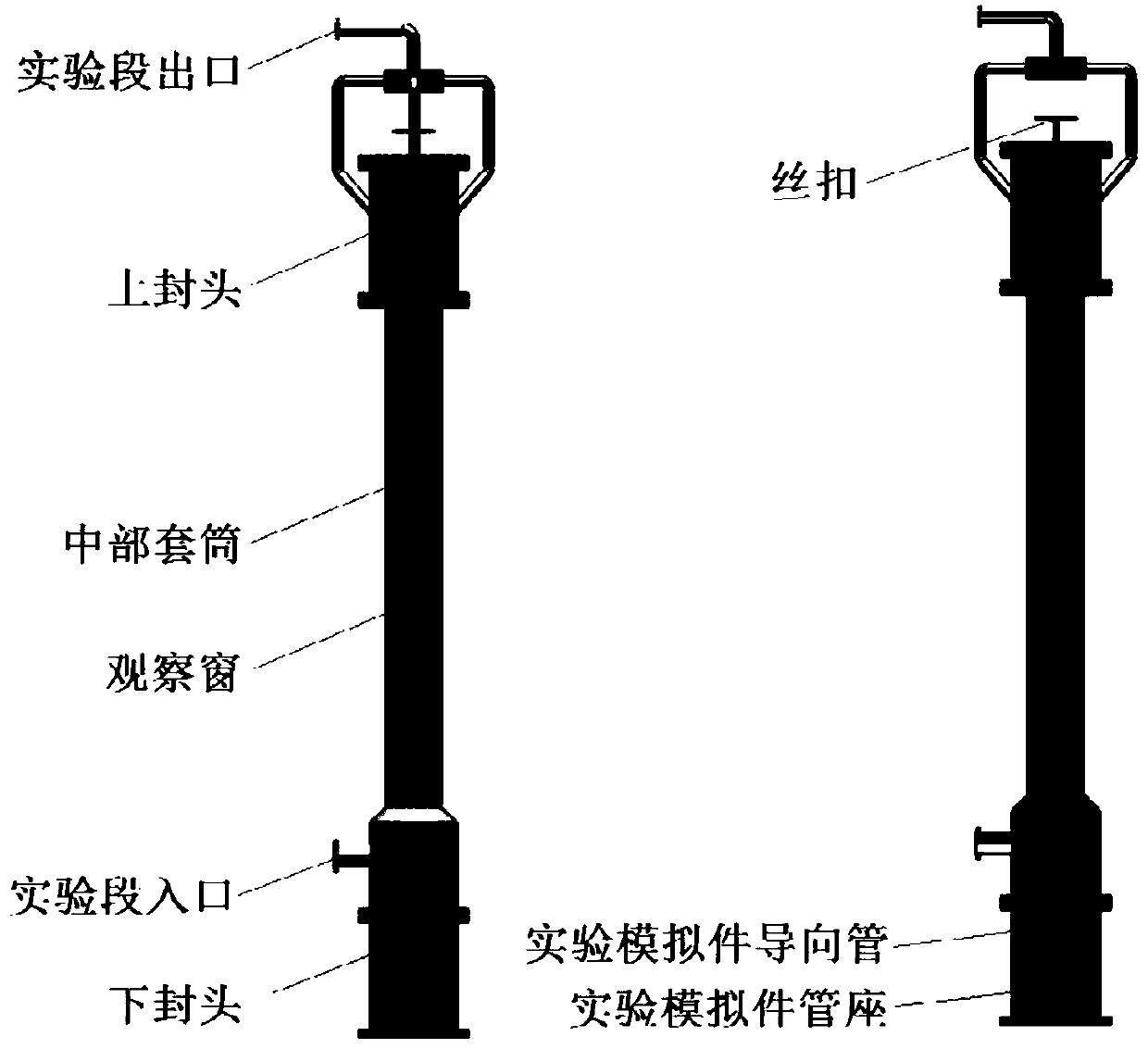

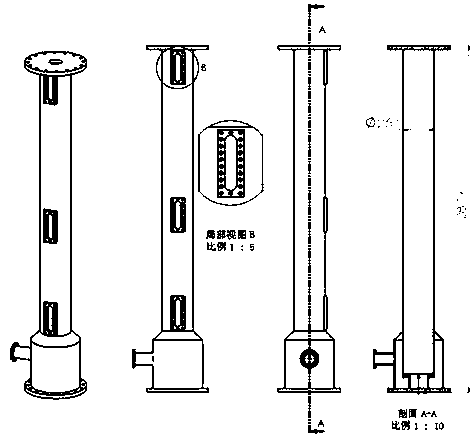

[0032] The embodiments will be described in detail below in conjunction with the accompanying drawings.

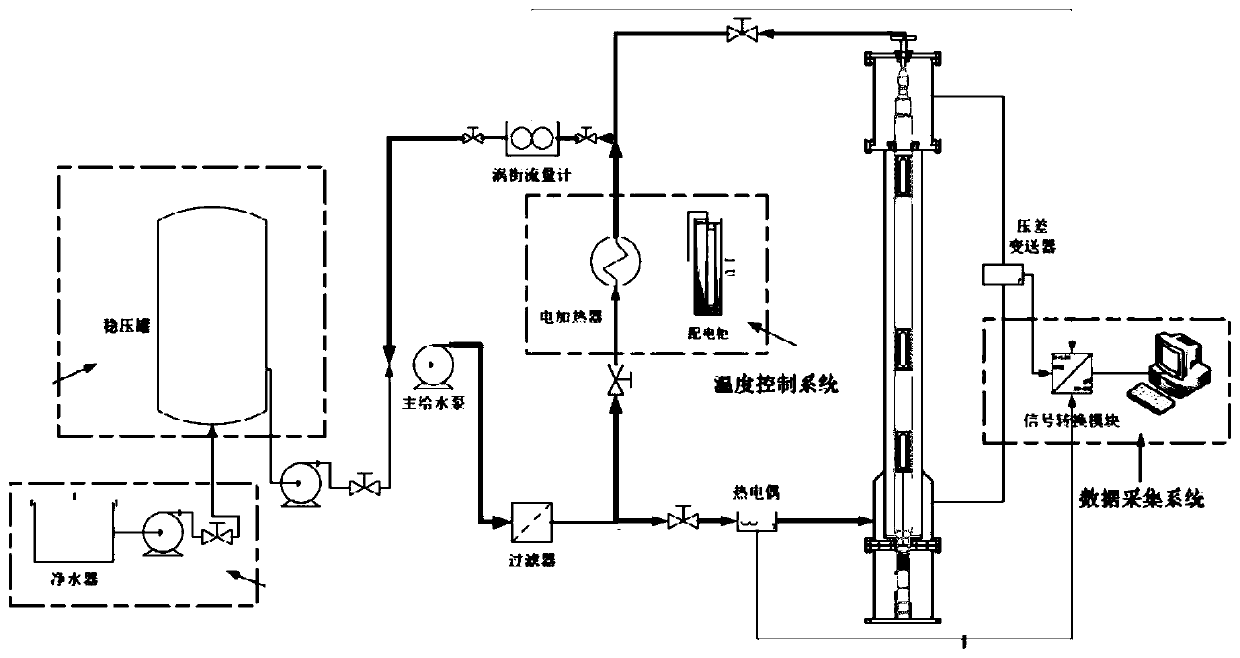

[0033] The experimental platform of the present invention is composed of a water purification system, a voltage stabilizing system, a main circulation system and an experimental section. The purification system includes deionized water equipment and a feed water pump. Due to the fine structure of the simulated components used in the experimental section, if there are large impurities in the experimental working fluid, it is easy to cause surface scaling or even impurity accumulation to block the flow channel. Therefore, The experiment uses deionized water equipment to prepare deionized water, and its conductivity is less than 0.5μs / cm, which meets the water quality requirements of the experiment, thus ensuring the reliability of the flow condition from the source and also conducive to the accuracy of the measurement; the voltage stabilization system mainly includes high Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com