Simulation accelerated fatigue test system for asphalt pavement

A fatigue test, asphalt pavement technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of long time and high cost of fatigue test devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

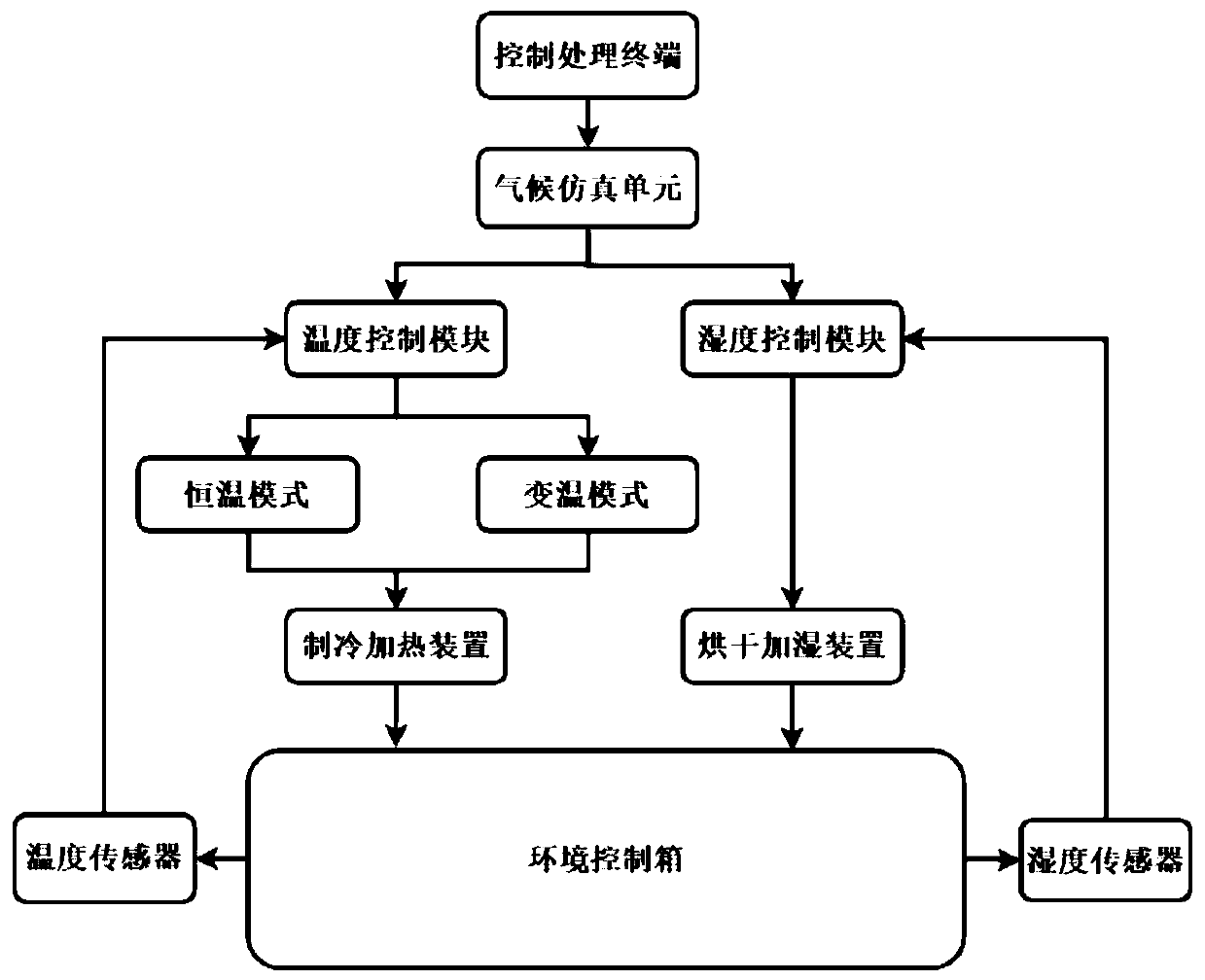

[0026] see Figure 1-3 , the present invention is a simulation accelerated fatigue test system for asphalt pavement:

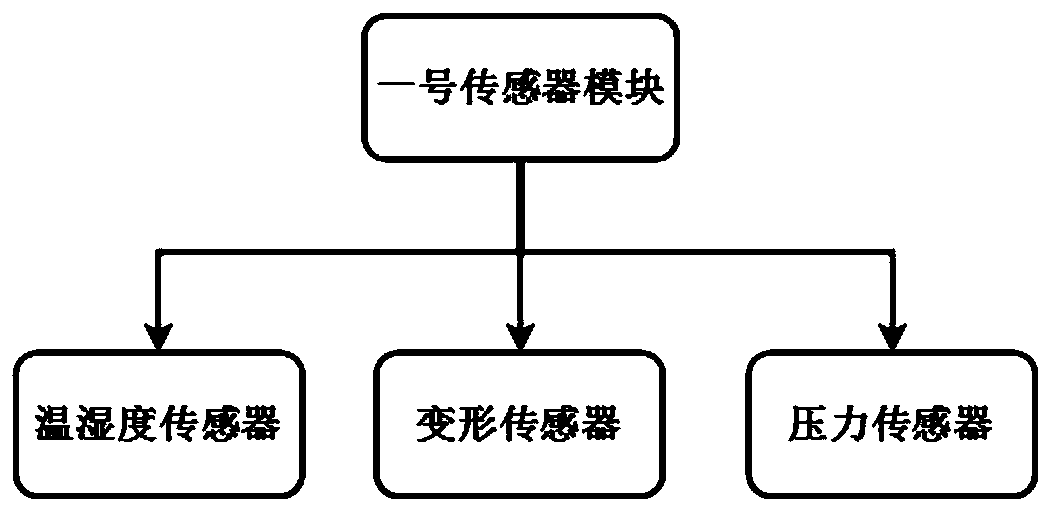

[0027] Including control processing terminal, climate simulation unit, environmental control box, load and strain measurement unit, rut depth measurement unit and data processing unit; the signal output terminal of the control processing terminal is connected with the climate simulation unit; the control processing terminal is equipped with control and data processing Software; the output end of the climate simulation unit is respectively connected to a temperature control module and a humidity control module; one end of the temperature control module and the humidity control module are connected to the environmental control box; the output end of the control processing terminal is connected to a PLC; the PLC is the controller; the PLC controller The model is FX1S-10MT-001; the PLC output is connected to the loading and strain measuring unit; the loading and s...

Embodiment 2

[0037] A specific application of this embodiment is: the present invention can carry out simulation tests on the test piece under various climatic conditions under the control of the control processing terminal, namely the computer, and measure the rut depth, fatigue crack, strain, stress and temperature of the test piece And other indicators; and automatically collect, form stress-strain curves and export data through the control processing terminal, that is, the computer; the time relationship of rut depth, temperature, humidity and crack growth data; the simulation test is carried out through the climate simulation unit, the temperature control module and The humidity control module controls the temperature and humidity data of the environment control box through the cooling and heating device and the drying and humidifying device. The temperature sensor and the humidity sensor are used to monitor the temperature and humidity data of the environment control box and feed back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com