Rotation and reciprocation stereoscopic pulping and double-drum supercharging rotation screening pulping and pulp screening equipment

A pulping, double-drum technology, used in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulping efficiency, low yield of good pulp, low pulp quality, etc., to increase strength and improve crushing and decomposition efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

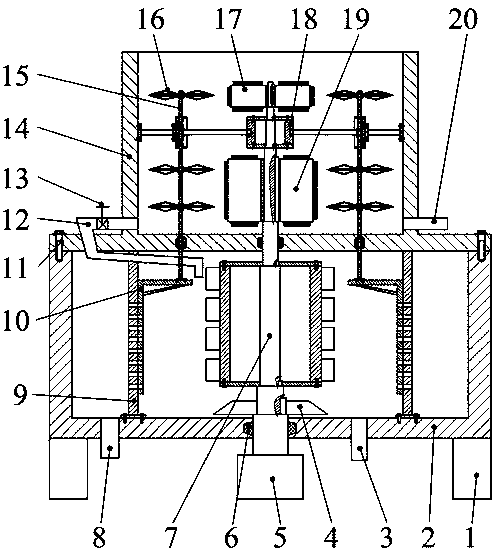

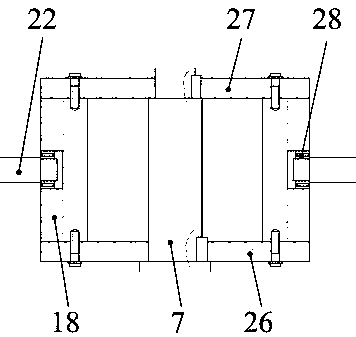

[0061] like figure 1 As shown in the figure, the crushing and screening equipment for rotary three-dimensional pulping and double-drum pressurized rotary screen of the present invention mainly includes a combined raw pulp screening device, a rotary power drive device, a rotary three-dimensional pulping device and a double-drum pressurized rotary screen. The drum pressurized rotary screen device, the rotary power drive device is installed on the combined raw pulp screen device, the rotary three-dimensional pulping device and the double-drum pressurized rotary screen device are installed in the combined raw pulp screen device from top to bottom. .

[0062] The present invention realizes the generation of the slurry and the screening of the good slurry by combining the good slurry screening device, that is, the mixed liquid of the scrap and water is crushed and decomposed in the barrel 14 to generate the slurry, and the slurry is screened in the screening barrel 2 to select the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com