Pulping device based on overturning-stirring and reciprocating turbulent slushing

A turbulence device and pulping technology, applied in textiles and papermaking, raw material separation, papermaking, etc., can solve the problems of low pulp quality and low efficiency, achieve the effect of ensuring pulp quality and improving crushing and decomposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

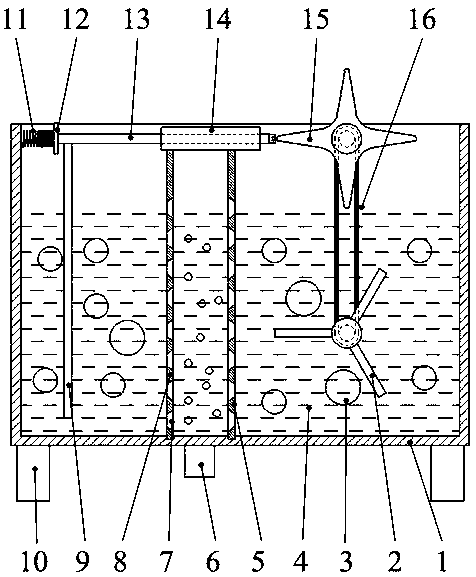

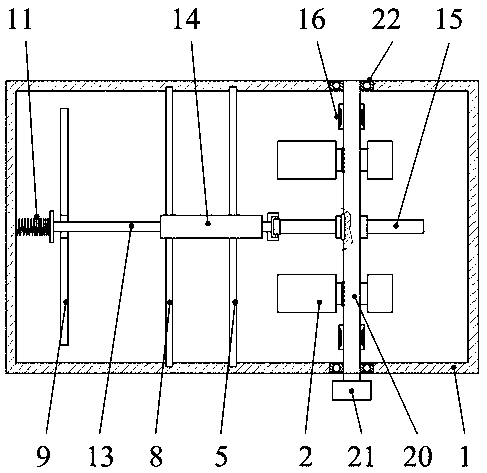

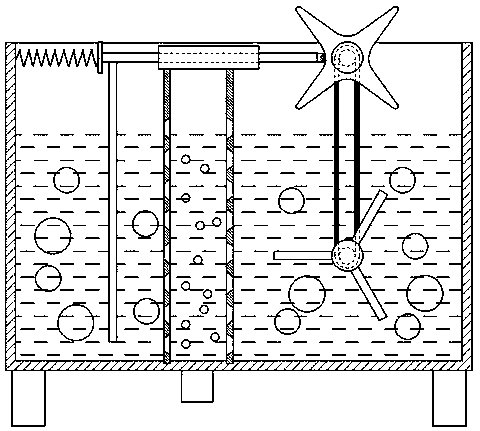

[0035] Such as figure 1 , figure 2 with image 3 As shown, a pulping device of the present invention based on turning stirring and reciprocating turbulence type pulping mainly includes a slurry generating device, a turning stirring device and a reciprocating flow turbulence device, and the slurry generating device is divided in turn from right to left. For the turning and stirring zone, the fine slurry filtering zone and the reciprocating flow disturbance zone, the turning and stirring device is arranged in the turning and stirring zone, and the reciprocating flow disturbing device is arranged in the reciprocating flow disturbing zone.

[0036] The turning and stirring area is surrounded by the side wall of the material box 1 and the filter plate A 5, the fine pulp filter area is surrounded by the side wall of the material box 1, the filter plate A 5 and the filter plate B 8, and the reciprocating turbulence area is surrounded by the side wall of the material box 1 And filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com