Ingredient composition for low-temperature compressed-gas fermented vegetables, low-temperature compressed-gas vegetable fermentation method thereof and processing method of fermented vegetables

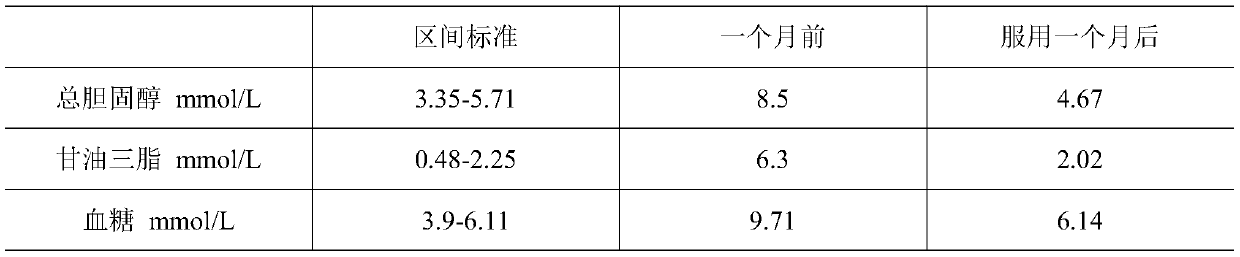

A technology of fermented vegetables and processing methods, applied in the fields of fruit and vegetable preservation, application, food science, etc., can solve the problems of difficult temperature control, shorten fermentation time, etc., achieve slow gas production, help nutrient absorption, and prevent cardiovascular diseases Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] An ingredient composition for low-temperature compressed air fermented vegetables, said ingredient composition used for low-temperature compressed air fermented vegetables is mainly composed of mustard heads, pomelo peels, purslane, edible salt, said low-temperature compressed air fermented vegetables In the ingredient composition of fermented vegetables, the parts by weight of mustard head are 20 parts, the parts by weight of pomelo peel are 20 parts, the parts by weight of purslane are 10 parts, the parts by weight of edible salt are 5 parts, 0.1 parts chitosan.

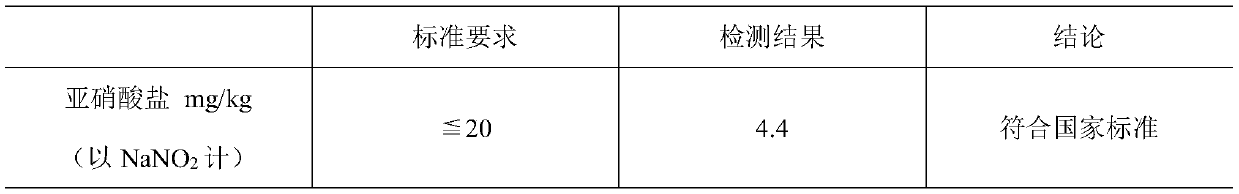

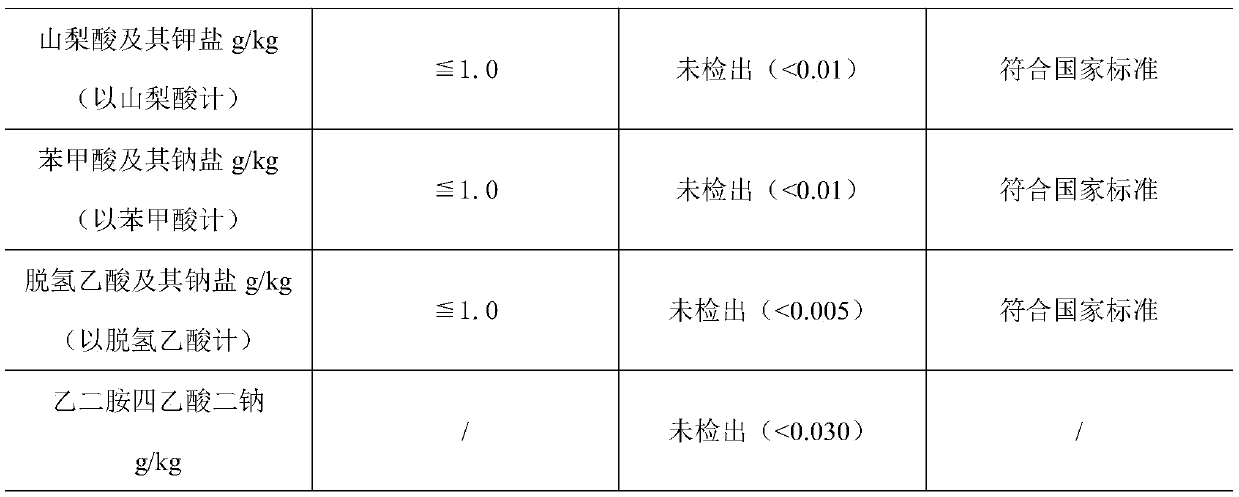

[0028] The ingredient composition used for low-temperature compressed air fermented vegetables described in this embodiment, mustard head, pomelo peel, and purslane have natural antiseptic effects, which can ensure that no beetroot is produced during the vegetable fermentation process, and the added chitosan and vegetable fermentation After the nitrite produced in the process is mixed, it reacts to generate ...

specific Embodiment approach 2

[0030] A method for fermenting vegetables with low-temperature compressed air, which uses the ingredient composition for low-temperature compressed-air fermented vegetables described in Embodiment 1.

[0031] A low-temperature compressed gas vegetable fermentation method described in this embodiment, after mixing fresh vegetables and an ingredient composition for low-temperature compressed gas fermented vegetables according to the ratio of 95:5, under the condition of a temperature of 2-5 ° C, sealed fermentation 130 day, the fermentation pressure was 0.1Mpa, and the fresh vegetables were cruciferous vegetables.

[0032] In the low-temperature compressed gas vegetable fermentation method described in this embodiment, the fresh vegetable is Chinese cabbage.

[0033] In the low-temperature compressed air vegetable fermentation method described in this embodiment, the vegetables are stacked in layers in the fermentation tank before fermentation. The odd-numbered layers adopt the ...

specific Embodiment approach 3

[0044] The low-temperature compressed air vegetable fermentation method is a method for processing fermented vegetables. The method for processing fermented vegetables includes processing vegetable stock and processing vegetables. The processing of vegetables includes processing shredded vegetables, processing vegetable fillings, processing vegetable hearts, and processing vegetables. processing of vegetables.

[0045] The method for processing fermented vegetables described in the low-temperature compressed air vegetable fermentation method described in this embodiment, the processing method of vegetable stock is to take fermented vegetable stock, filter, heat at 100°C for 5-10 minutes, cool to room temperature, and fill to obtain vegetable stock .

[0046] The processing method of the fermented vegetables of the low-temperature compressed gas vegetable fermentation method described in the present embodiment, the processing method of vegetables comprises the following steps: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com