Trailer coupling having a connection device

A technology of coupling device and connecting device, which is applied in the direction of traction connector, vehicle parts, transportation and packaging, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

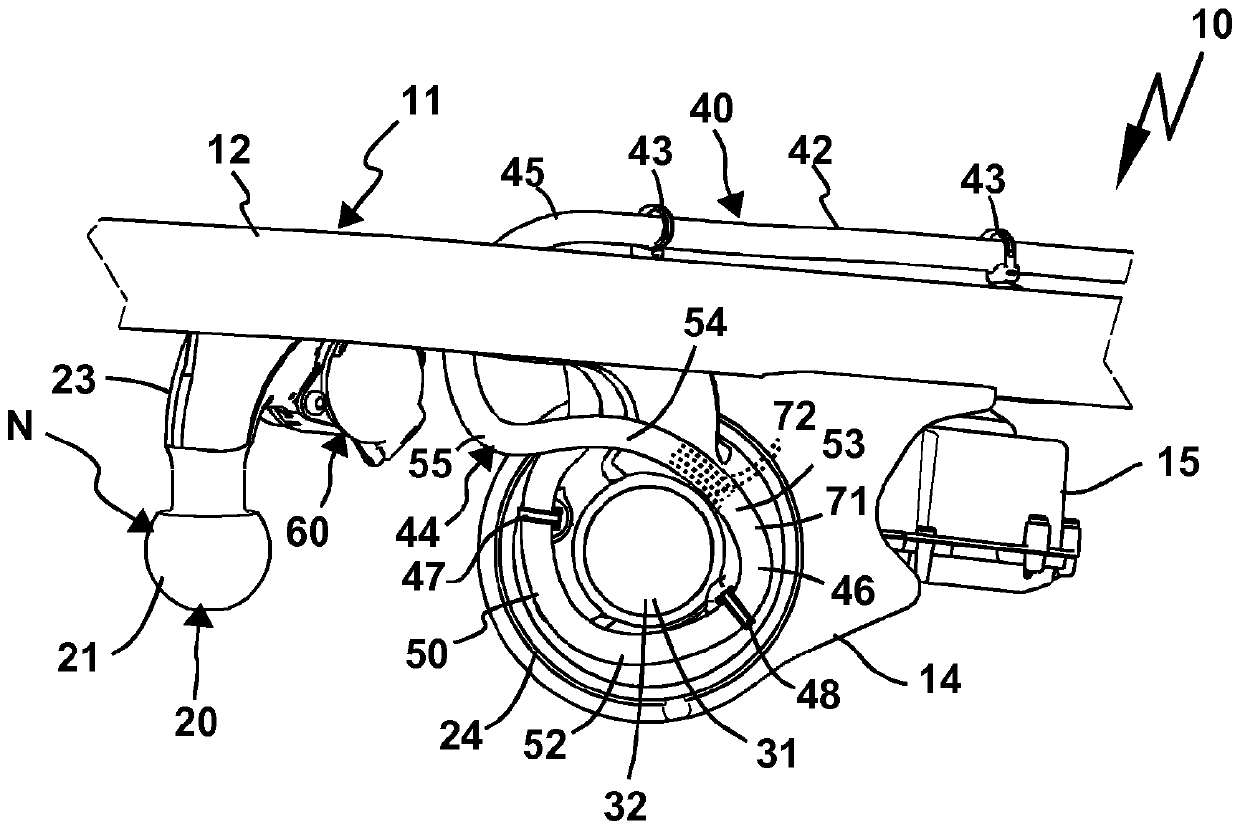

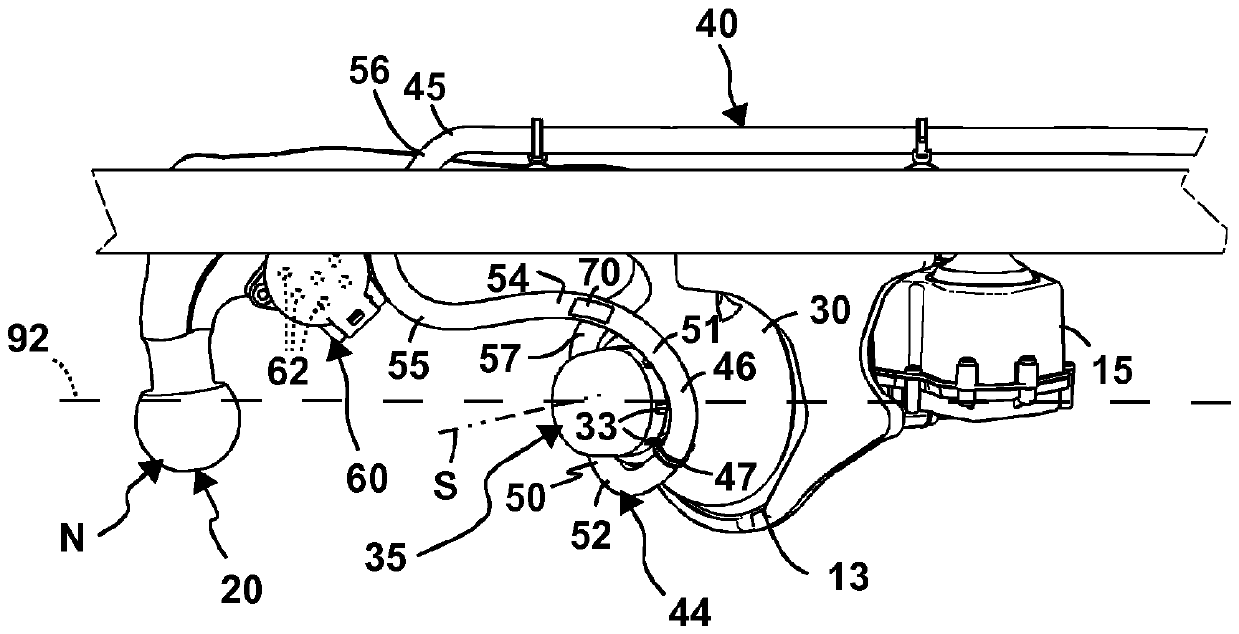

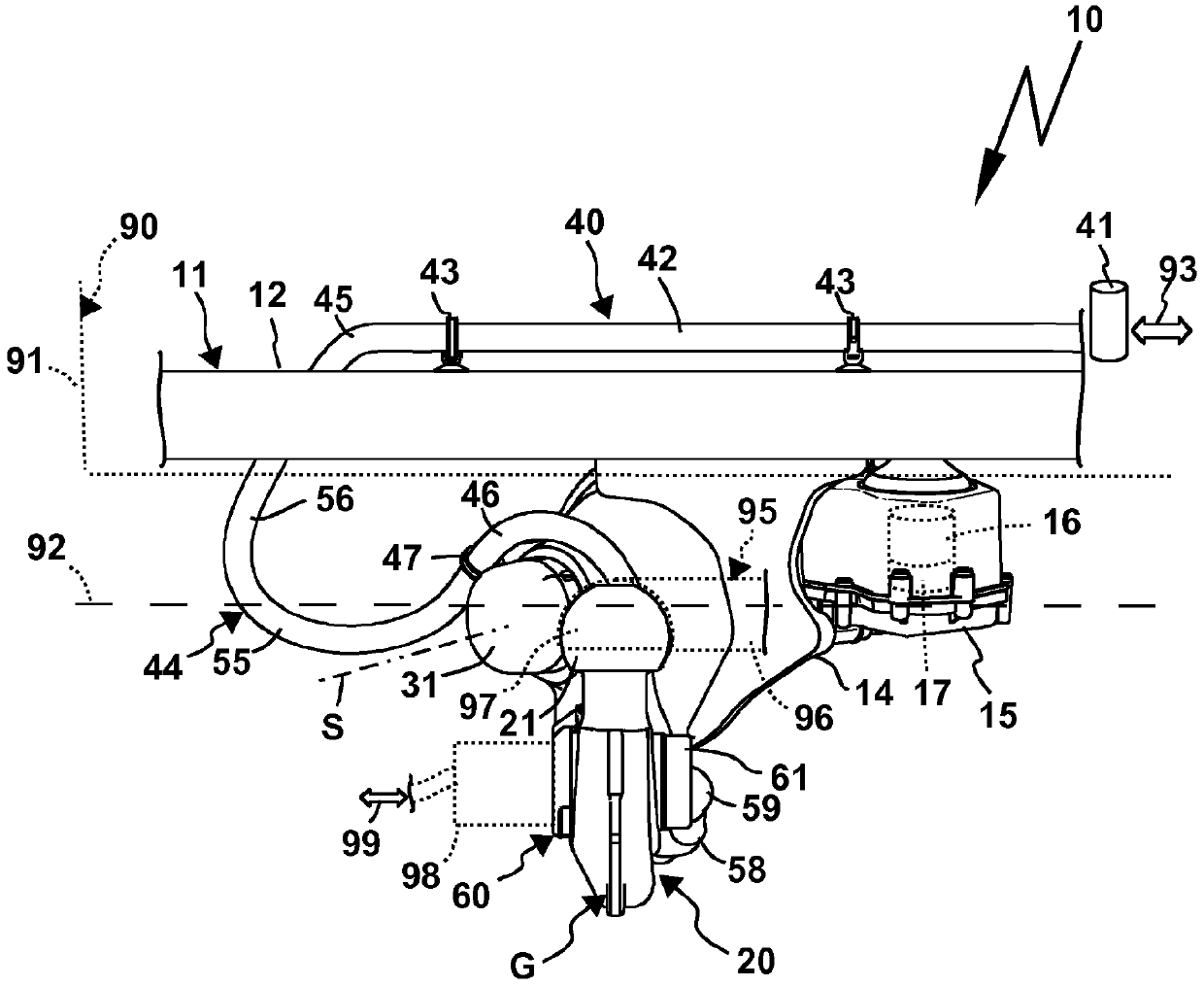

[0049] In the trailer coupling devices 10 , 110 shown in the figures, partially identical or functionally identical components are provided, for which reason the same or similar reference numerals are used in this regard. In order to illustrate the difference between the embodiments 10 and 110, reference numerals differing by 100 are generally used.

[0050] The trailer coupling 10 includes a bracket assembly 11 with a cross member 12 which extends, for example, transversely at the rear of the motor vehicle 90 . The cross member 12 is fastened to the body 91 of the motor vehicle 90 , for example via side members. The side members (not shown) are screwed together with the body 91, for example. The side member can extend laterally on the body in the direction of travel along the longitudinal direction of the motor vehicle 90 on the outer side or can also be arranged on the rear side of the vehicle.

[0051] The bracket assembly 12 is thus connected to the body 91 of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com