A method for quickly determining the solid content of phosphoric acid by using a centrifuge

A rapid measurement and centrifuge technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of short measurement operation time, low product quality, adjustment lag, etc., and achieve short measurement operation time, simple operation process and easy operation The principle is easy to understand and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

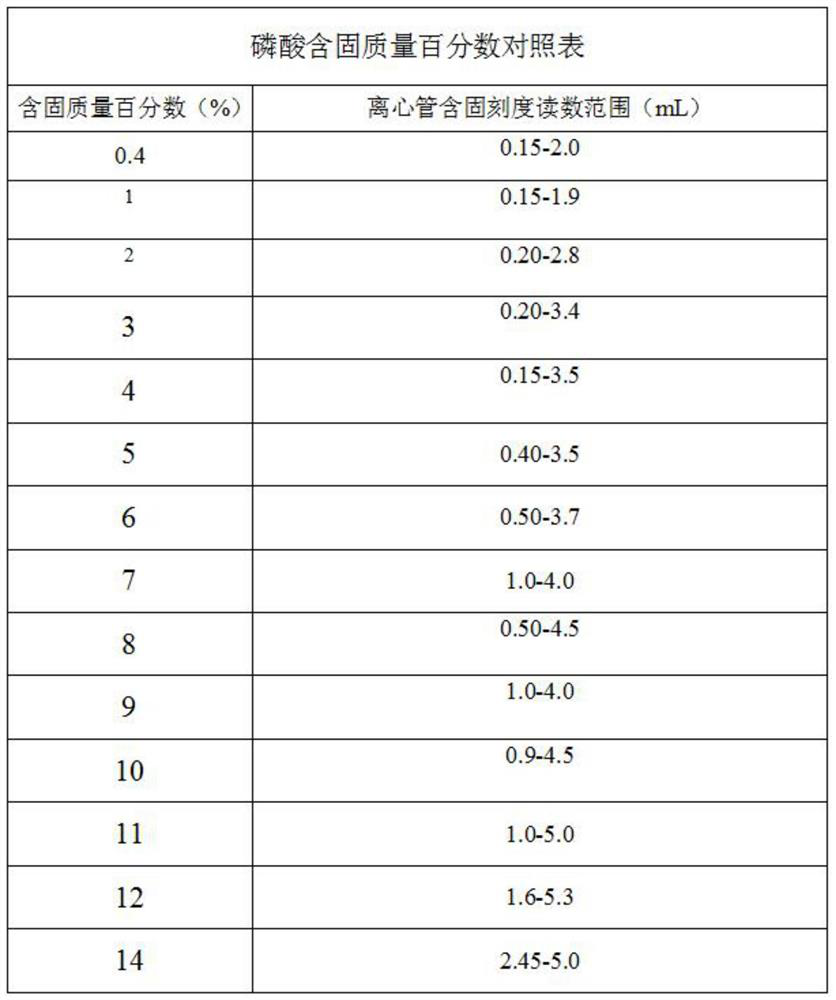

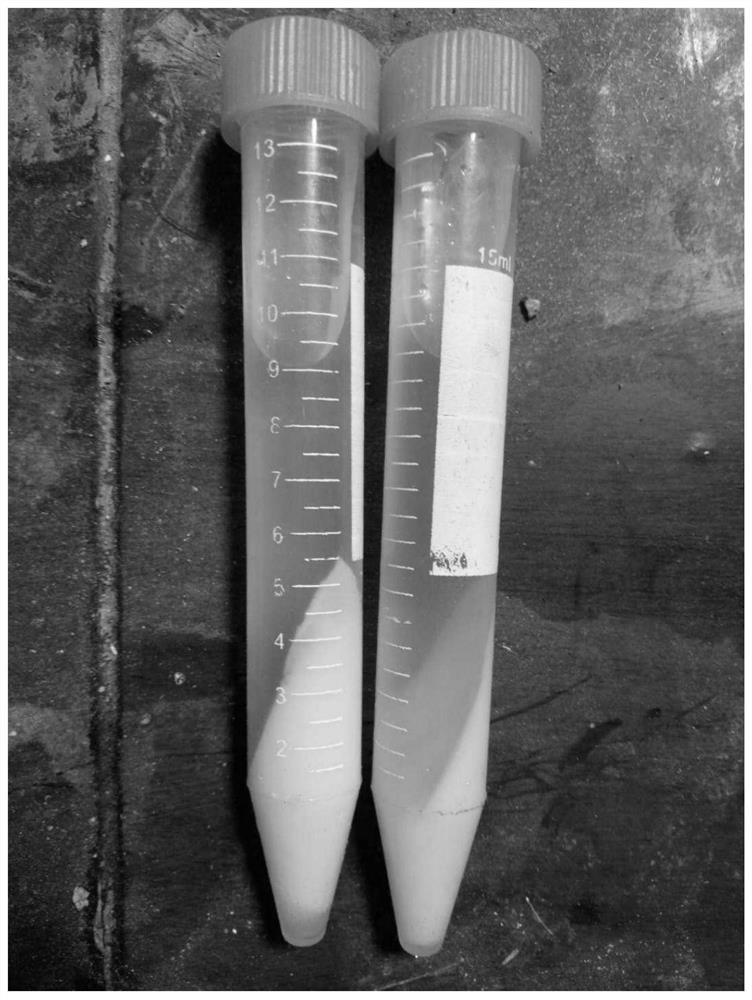

[0025] (1) Prepare 12 groups of phosphoric acid solutions with different solid gradients, the solid contents are respectively 0.4%, 1%, 2%, 3%, 4%, 5%, 6%, 8%, 10%, 11%, 12 %, 14%, and accurately measure the exact solid value of each solid-containing gradient phosphoric acid, measure 3 times, and then take the average value;

[0026] (2) For the phosphoric acid solution whose solid content has been accurately determined in step (1), the solid content of the centrifuge is determined. The amount of phosphoric acid added to each test tube is 12ml. The scale value of the test tube;

[0027] (3) Organize the experimental data of the centrifugal results of each group of centrifuges, carry out data analysis, and draw a standard curve diagram to form a centrifuge measurement test tube scale and a solid comparison table;

[0028] (4) Configure four types (clean acid: solid content less than 2%; muddy acid: solid content 2%-4%; silted acid: solid content 6%-8%; slag acid: solid content...

Embodiment 2

[0031] (1) prepare 10 groups of phosphoric acid solutions with different solid-containing gradients, the solid contents are respectively 0.4%, 1%, 2%, 4%, 6%, 8%, 10%, 11%, 12%, 14%, and Accurately measure the exact solid value of each solid-containing gradient phosphoric acid, measure 3 times, and then take the average value;

[0032] (2) For the phosphoric acid solution whose solid content has been accurately determined in step (1), the solid content of the centrifuge is measured. The amount of phosphoric acid added to each test tube is 10ml. The scale value of the test tube;

[0033] (3) Organize the experimental data of the centrifugal results of each group of centrifuges, carry out data analysis, and draw a standard curve diagram to form a centrifuge measurement test tube scale and a solid comparison table;

[0034] (4) Configure four types (clean acid: solid content less than 2%; muddy acid: solid content 2%-4%; silted acid: solid content 6%-8%; slag acid: solid content...

Embodiment 3

[0037] (1) Prepare 14 groups of phosphoric acid solutions with different solid gradients, the solid contents are 1%, 2%, 3%, 4%, 5%, 6%, 7%, 8%, 9%, 10%, 11 %, 12%, 13%, 14%, and accurately measure the exact solid value of each solid-containing gradient phosphoric acid, measure 3 times, and then take the average value;

[0038] (2) For the phosphoric acid solution whose solid content has been accurately determined in step (1), the solid content of the centrifuge is measured. The amount of phosphoric acid added to each test tube is 15ml. The scale value of the test tube;

[0039] (3) Organize the experimental data of the centrifugal results of each group of centrifuges, carry out data analysis, and draw a standard curve diagram to form a centrifuge measurement test tube scale and a solid comparison table;

[0040] (4) Configure four types (clean acid: solid content less than 2%; muddy acid: solid content 2%-4%; silted acid: solid content 6%-8%; slag acid: solid content 10% -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com