Axial moving adjusting system for cylindrical welding part on welding roller frame

An adjustment system, axial movement technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of ineffective automatic adjustment function of the anti-axial movement roller frame, so as to solve the problem of difficult processing. , The shape is simple, the effect of avoiding the shaft displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

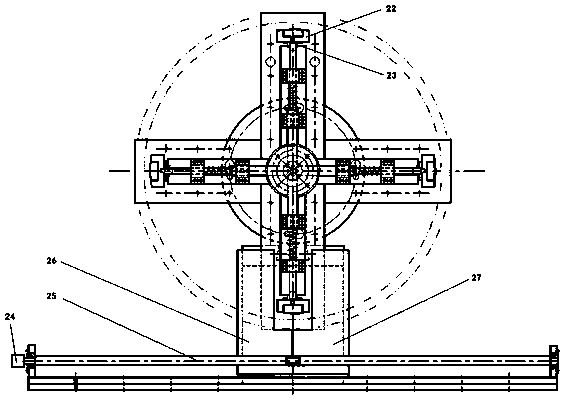

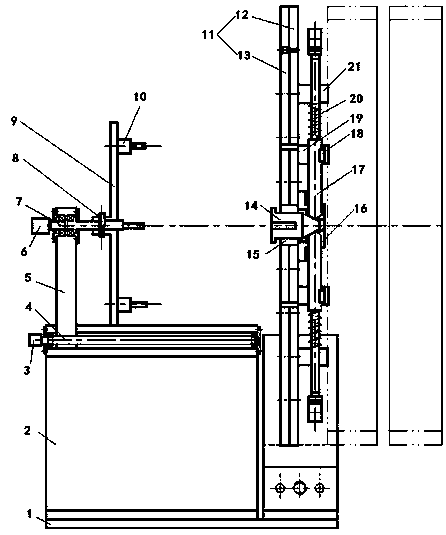

[0038] As shown in the figure, the specific implementation is as follows:

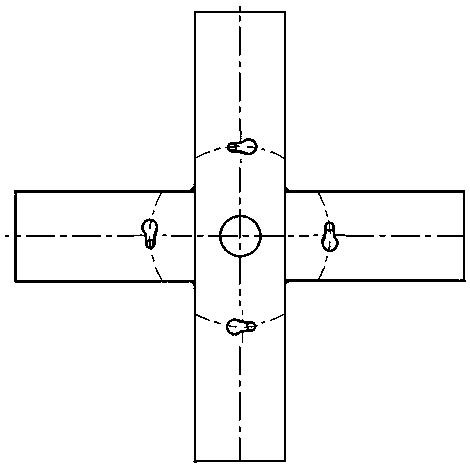

[0039] A system for adjusting the axial movement of a cylindrical weldment on a welding roller frame, including a pair of driving rollers 36 for supporting the cylindrical weldment 29. The driving rollers 36 are connected with a power mechanism to drive it to rotate. The rollers 36 are parallel to each other and are supported tangentially below the cylindrical weldment 29. One end of one of the driving rollers is also provided with a first driven roller 34 whose axis coincides with the axis of the driving roller. The first driven roller 34 It is tangent to the cylindrical weldment 29, and the first driven roller 34 slides horizontally along the direction of the center line of the two driving rollers 36, and the direction of the first driven roller 34 away from the cylindrical weldment 29 is defined as the a direction, which defines the first driven roller 34. The direction of a driven roller 34 approac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com