Capsule defect shot blasting full-inspection device

A capsule and defect technology, applied in the field of image processing capsule defect shot blasting detection, can solve the problems of low application efficiency, inaccurate 360-degree detection of capsules, complex structure of the detection system, etc., achieving comprehensive detection, high detection efficiency and high degree of automation , the effect of simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

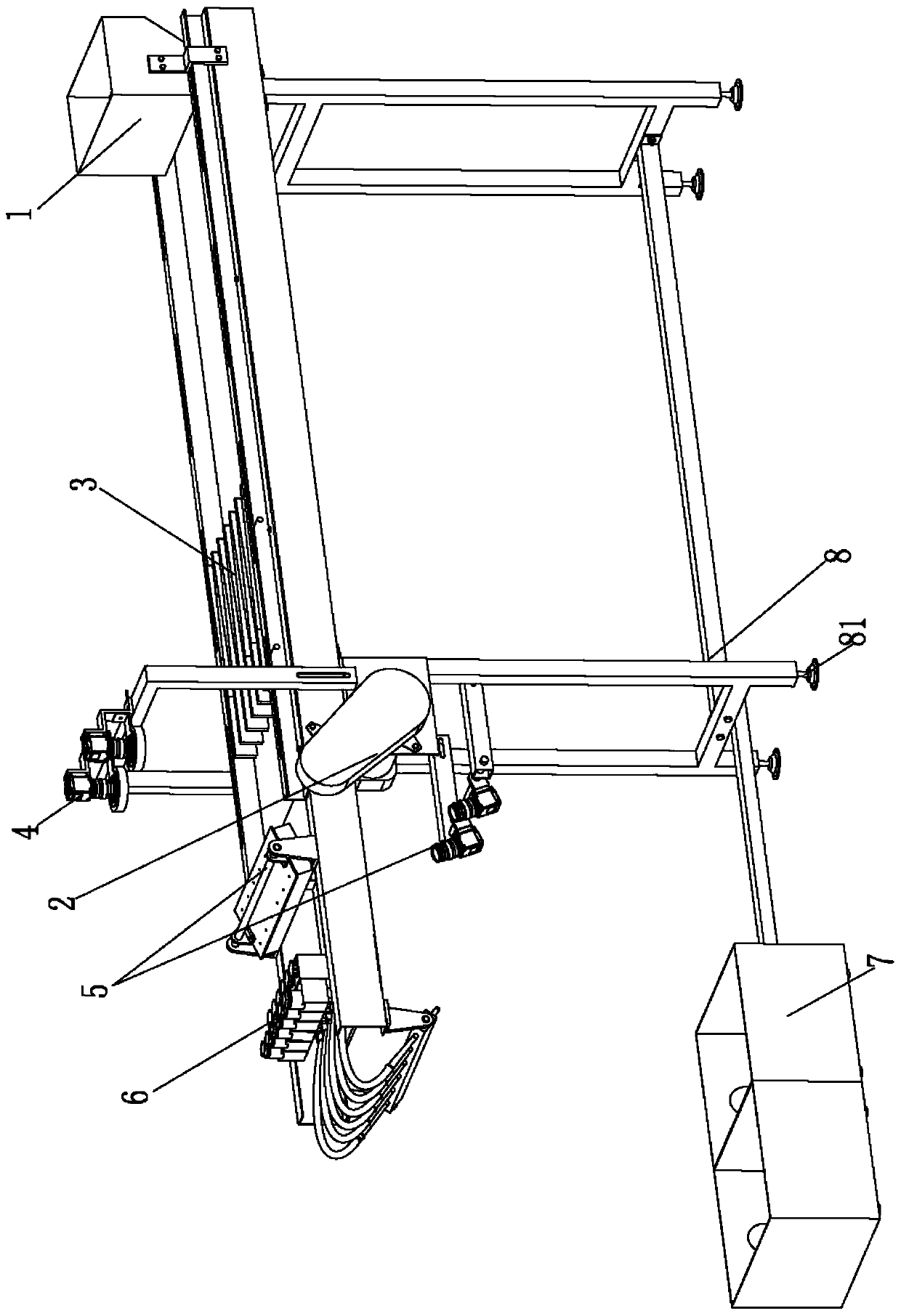

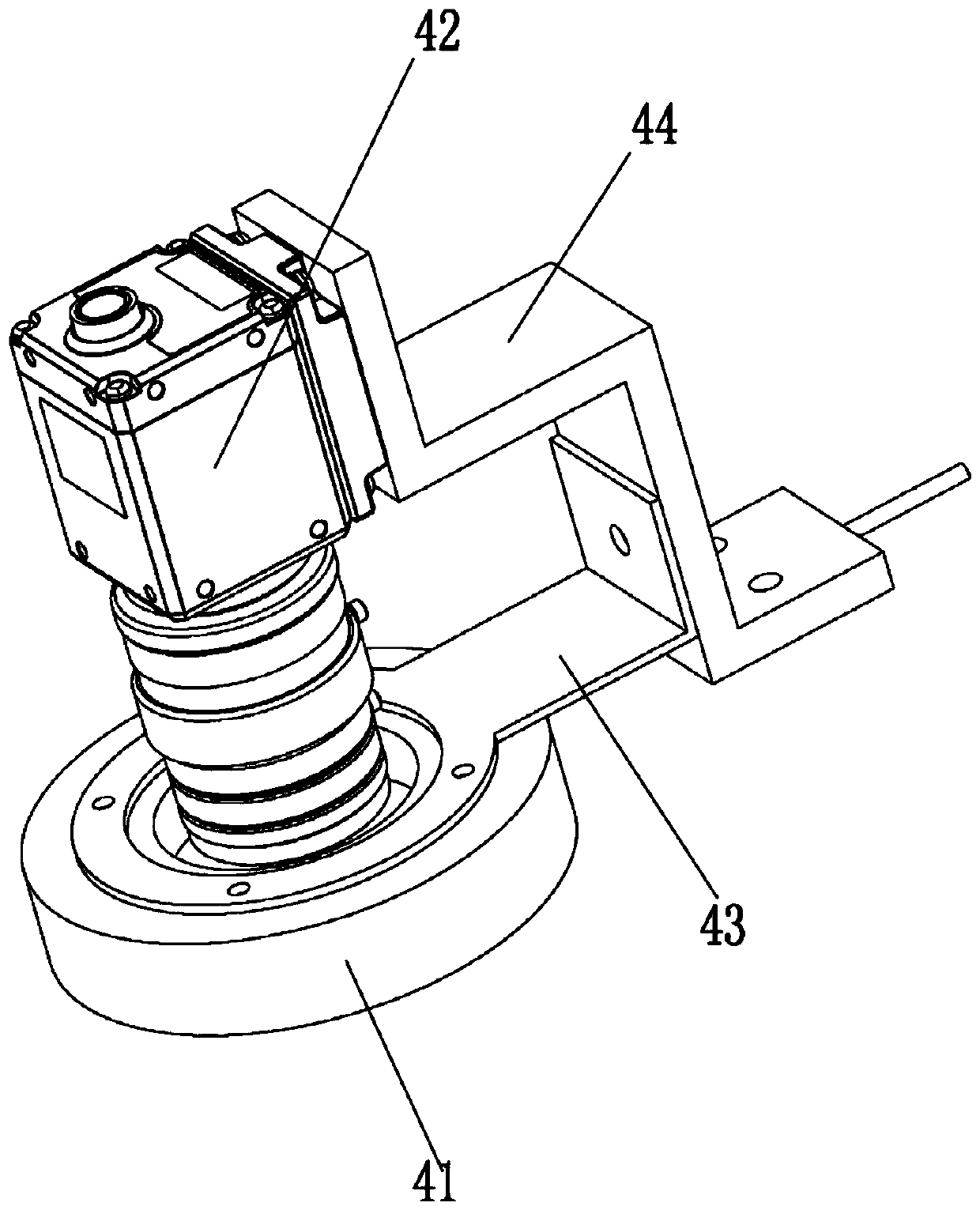

[0027] Please refer to the attached figure 1 to attach Figure 6 As shown, the present invention is a full inspection device for capsule defect shot blasting, which consists of a support frame 8 and a feeding device 1 installed on the support frame 8, a motor and a transmission chain 2, a belt conveyor 3, and a first image acquisition device 4. The second image acquisition device 5, the jet rejecting device 6 and the collecting device 7 are composed of several parts.

[0028] Wherein, the feeding device 1 is located above one end of the belt conveying device 3, and the capsules to be detected are contained therein.

[0029] The motor and the transmission chain 2 are connected and drive the belt conveyor 3, and the capsules fed from the feeding device 1 are conveyed by the belt conveyor 3, and the capsules are separated into linear motions along the conveyor belt track.

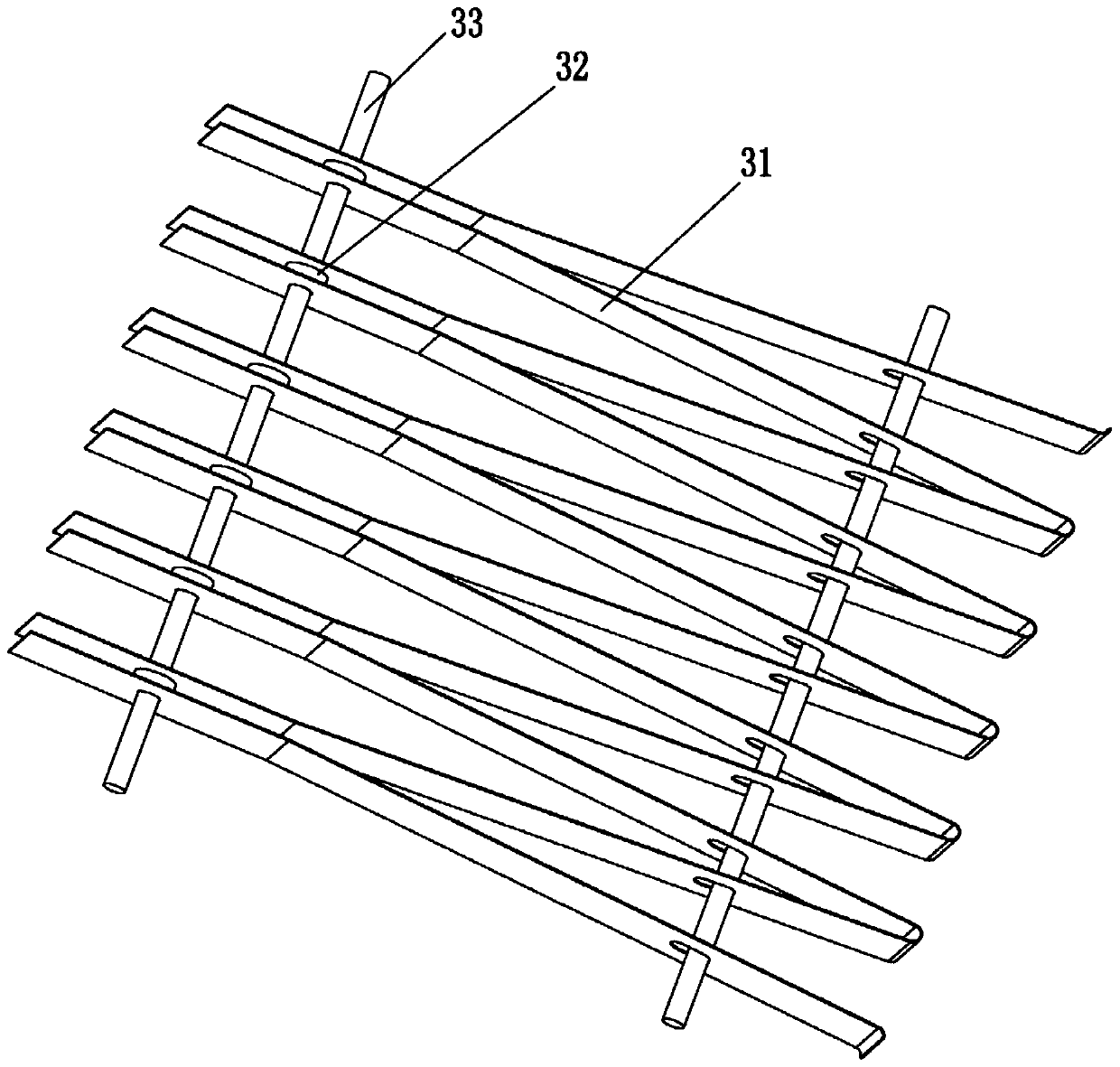

[0030] The belt conveyor 3 includes a separator shaft 33 passing through the separator 31 . The separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com