Vacuum sweeper truck bed and vacuum sweeper

A technology for vacuuming vehicles and carriages, which is applied in the field of sanitation vehicles. It can solve the problems of low utilization rate of filtration area, short continuous operation cycle, and influence on work efficiency, and achieve simple and efficient installation and maintenance, long continuous working time, and high filter element utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

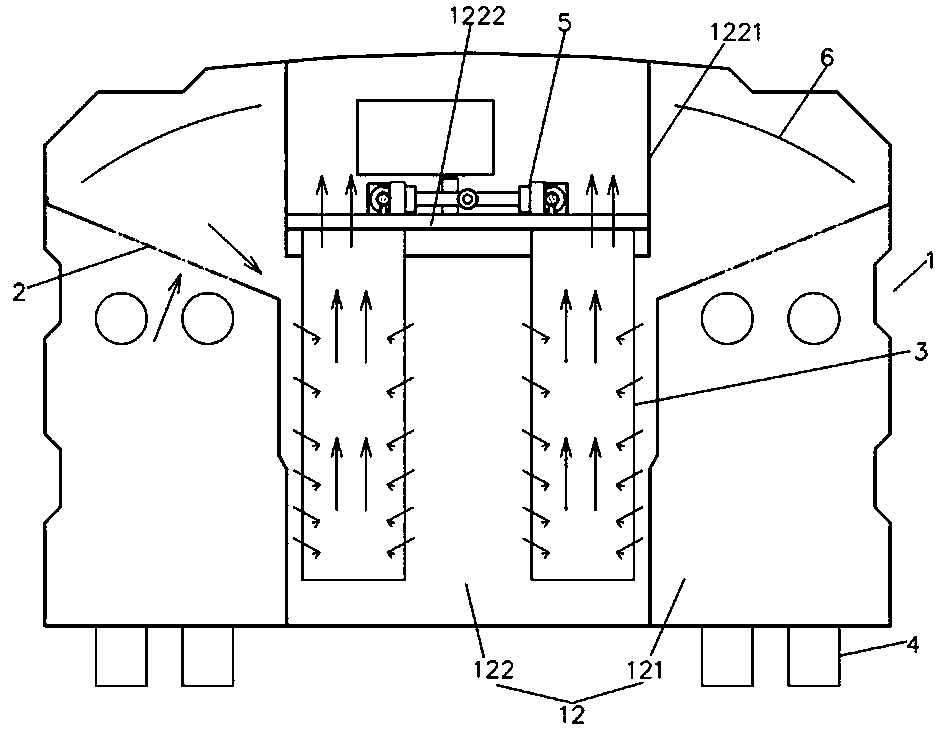

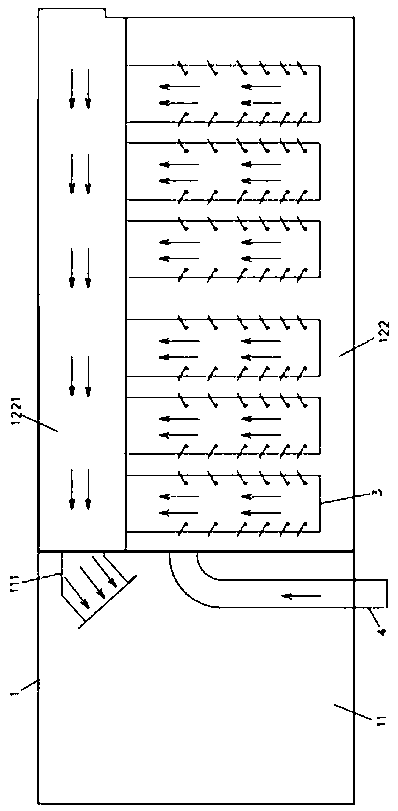

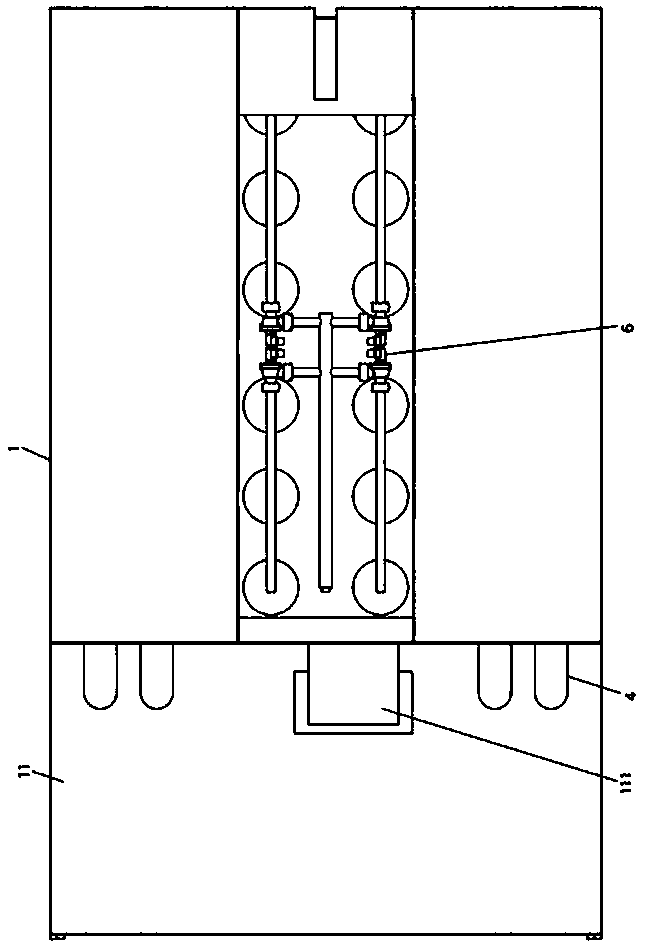

[0032] Embodiment one: if Figures 1 to 3 As shown, the dust collection vehicle compartment of this embodiment includes a box body 1, the box body 1 is a cuboid shape arranged horizontally along the front and rear directions, and its interior is provided with mutually independent air outlet bins 11 and dust removal bins 12 along the front and rear directions. At least one side of the left and right direction inside the dust removal chamber 12 is provided with an air inlet chamber 121, and the remaining part forms a filter chamber 122. An air duct 1221 extending to the front and rear ends is provided along the front and rear direction, and the air outlet 111 communicating with the air duct 1221 is provided inside the above-mentioned air outlet bin 11; the coarse-effect filter device 2, the above-mentioned coarse-effect filter device 2 is detachable The above-mentioned air hole is installed at the above-mentioned air hole; the filter element 3, the above-mentioned filter element...

Embodiment 2

[0050] Embodiment 2: This embodiment provides a dust collection truck compartment, including the dust collection truck compartment in Embodiment 1. During the assembly process, the power supply of the electrical components inside the compartment is connected to the vehicle power supply of the entire dust collection truck, and involves The control circuit or controller of the electronically controlled device is installed in the cab of the vacuum cleaner, which is convenient for the driver to operate with one button.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com