Improved needle machine

A needle loom and frame technology, applied in the field of needle looms, can solve problems such as difficult lifting of needles, bending of non-woven fibers, and many broken needles of products, so as to optimize the internal structure and pore distribution, and increase the content of longitudinal reinforcing fibers , Improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

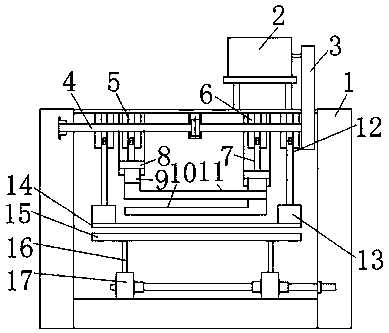

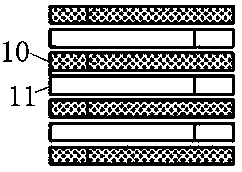

[0011] Such as figure 1 and figure 2 As shown, a kind of improved acupuncture machine of the present invention, it comprises frame 1, is provided with motor 2 on the upper side of described frame 1, and described motor 2 is connected with horizontal rotating shaft 4 through belt 3, so The horizontal rotating shaft 4 is installed on the frame 1 through bearings, and two connecting rod necks are arranged on the horizontal rotating shaft 4, which are respectively connecting rod neck I5 and connecting rod neck II6, and the connecting rod neck is connected with the connecting rod 7 , the connecting rod 7 is connected to the piston 8, the piston 8 is connected to the push rod 9, the push rod 9 is connected to the needle plate, the needle plate is divided into needle plate I10 and needle plate II11, needle plate I10 and needle plate The plates II11 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com